Abstract

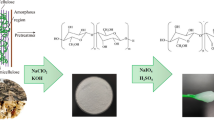

Synthesis of useful products from waste material improves the process economy and sustainability. Cellulose nanocrystals (CNCs) have unique properties like nanoscale dimensions and excellent mechanical strength. CNCs can be synthesized from Banana pseudostem, the renewable agro-waste. In a two-step process for isolation of CNCs, chemically purified cellulose (CPC) was obtained from raw fibers and CNCs were isolated from CPC by acid hydrolysis method. The effect of chemical treatments on properties of prepared CNCs was investigated. The effect of hydrolysis reaction time on the morphology of cellulose nanocrystals was also studied. It was observed that partial lignin and hemicellulose with other extractives were removed during alkali treatment. FTIR analysis indicated that peaks at 1730 cm−1 and 1250 cm−1 only were present in the spectrum of raw fibers. It indicated the removal of lignin, hemicellulose, and waxes after pre-treatment. The spectrum for treated cellulose indicated that most of the lignin and hemicelluloses were washed out in alkali treatment. Rod-like nanocrystals with average length 500 nm and diameter 80 nm were observed from FE-SEM images. Increase in crystallinity with successive treatments, from raw fibers (18.2%) to CNCs (64.2%), was observed from XRD analysis. CNCs have lower thermal stability than the raw fibers as observed from thermogravimetric analysis. The percentage crystallinity was found to be 18.2% for raw fibers. The diffractogram of raw fibers also indicated increase in % crystallinity value upon alkali treatment (52.4%) and bleaching treatment (62.6%). The hydrodynamic size (Z average) of CNC was 140.3 nm.

Similar content being viewed by others

Data Availability

No additional data and materials are associated with this article to support the findings of the article.

References

Mohanty, A. K., Misra, M., & Drzal, L. T. (2002). Sustainable bio-composites from renewable resources: Opportunities and challenges in the green materials world. Journal of Polymers and the Environment, 10(1), 19–26.

La Mantia, F. P., & Morreale, M. (2011). Green composites: A brief review. Composites Part A: Applied Science and Manufacturing, 42(6), 579–588.

Thakur, V. K., & Thakur, M. K. (2015). Recent advances in green hydrogels from lignin: A review. International Journal of Biological Macromolecules, 72, 834–847.

Saxena, M., Pappu, A., Sharma, A., Haque, R., & Wankhede, S. (2011). Composite materials from natural resources: Recent trends and future potentials. In: Tesinova P (Ed). IntechOpen. Advances in Composite Materials-Analysis of Natural and Man- Made Materials, 121–162. https://doi.org/10.5772/18264

Alzate Acevedo, S., Díaz Carrillo, A. J., Florez-Lopez, E., & Grande-Tovar, C. D. (2021). Recovery of banana waste-loss from production and processing: A contribution to a circular economy. Molecules, 26, 1–30. https://doi.org/10.3390/molecules26175282

Ultra, V. U., Mendoza, D. M., & Briones, A. M. (2005). Chemical changes under aerobic composting and nutrient supplying potential of banana residue compost. Renewable Agriculture and Food Systems, 20(2), 113–125.

Li, K., Fu, S., Zhan, H., Zhan, Y., & Lucia, L. (2010). Analysis of the chemical composition and morphological structure of banana pseudo-stem. BioResources, 5(2), 576–585.

Jústiz-Smith, N. G., Virgo, G. J., & Buchanan, V. E. (2008). Potential of Jamaican banana, coconut coir and bagasse fibres as composite materials. Materials Characterization, 59(9), 1273–1278.

El-Ramad, H., El-Henawy, A., Amer, M., Omara, A. E., Elsakhawy, T., Elbasiouny, H., Elbehiry, F., Elyazid, D. A., & El-Mahrouk, M. (2020). Agricultural waste and its nano-management: Mini review. Egypt Journal Soil Science, 60(4), 349–366.

Mukhopadhyay S, Fangueiro R, Arpaç Y, & Şentürk Ü (2008) Banana fibers- Variability and fracture behaviour. Journal of Engineered Fabrics & Fibers (JEFF), 3(2), 39–45.

Tashiro, K., & Kobayashi, M. (1991). Theoretical evaluation of three-dimensional elastic constants of native and regenerated celluloses: Role of hydrogen bonds. Polymer, 32(8), 1516–1526.

Siró, I., & Plackett, D. (2010). Microfibrillated cellulose and new nanocomposite materials: A review. Cellulose, 17(3), 459–494.

Wei, H., Rodriguez, K., Renneckar, S., & Vikesland, P. J. (2014). Environmental science and engineering applications of nanocellulose-based nanocomposites. Environmental Science: Nano, 1(4), 302–316.

Habibi, Y., Lucia, L. A., & Rojas, O. J. (2010). Cellulose nanocrystals: Chemistry, self- assembly, and applications. Chemical Reviews, 110(6), 3479–3500.

Beck-Candanedo, S., Roman, M., & Gray, D. G. (2005). Effect of reaction conditions on the properties and behavior of wood cellulose nanocrystal suspensions. Biomacromolecules, 6(2), 1048–1054.

Dong, X. M., Revol, J. F., & Gray, D. G. (1998). Effect of microcrystallite preparation conditions on the formation of colloid crystals of cellulose. Cellulose, 5(1), 19–32.

Dong, X. M., Kimura, T., Revol, J. F., & Gray, D. G. (1996). Effects of ionic strength on the isotropic− chiral nematic phase transition of suspensions of cellulose crystallites. Langmuir, 12(8), 2076–2082.

Dufresne, A. (2006). Comparing the mechanical properties of high performances polymer nanocomposites from biological sources. Journal of Nanoscience and Nanotechnology, 6(2), 322–330.

Strømme, M., Mihranyan, A., & Ek, R. (2002). What to do with all these algae? Materials Letters, 57(3), 569–572.

Roman, M., & Winter, W. T. (2004). Effect of sulfate groups from sulfuric acid hydrolysis on the thermal degradation behavior of bacterial cellulose. Biomacromolecules, 5(5), 1671–1677.

Garcia, E. G. J. G., Mora, K. R., & Bernal, C. (2020). Cellulose nanofiber production from banana rachis. International Journal of Engineering Science and Computing, 10(2), 24683–24690.

Kargarzadeh, H., Ioelovich, M., Ahmad, I., Thomas, S., & Dufresne, A. (2017). Methods for extraction of nanocellulose from various sources. In: Kargarzadeh, H., Ahmad, I., Thomas, S., & Dufresne, A. (Eds.) Handbook of Nanocellulose and Cellulose Nanocomposites, 1st Edn. Wiley-VCH Verlag GmbH & Co. KGaA., 1–50.

Owoyokun, T., Berumen, C. M. P., Luevanos, A. M., Cantu, L., & Ceniceros, A. C. L. (2021). Cellulose nanocrystals: Obtaining and sources of a promising bionanomaterial for advanced applications. Biointerface Research in Applied Chemistry, 11(4), 11797–11816. https://doi.org/10.33263/BRIAC114.1179711816

Tibolla, H., Pelissari, F. M., Martins, J. T., Vicente, A. A., & Menegalli, F. C. (2018). Cellulose nanofibers produced from banana peel by chemical and mechanical treatments: Characterization and cytotoxicity assessment. Food Hydrocolloids, 75, 192–201. https://doi.org/10.1016/j.foodhyd.2017.08.027

Amina, K. N. M., Annamalaia, P. K., Morrowc, I. C., & Martina, D. (2015). Production of cellulose nanocrystals via a scalable mechanical method. RSC Advances, 5, 57133–57140. https://doi.org/10.1039/C5RA06862B

Cecci, R. R. R., Passos, A. A., Neto, T. C. d.A, & Silva, L. A. (2020). Banana pseudostem fibres characterization and comparison with reported data on jute and sisal fibers. SN Applied Sciences, 2(20). https://doi.org/10.1007/s42452-019-1790-8

Correa, A. C., Carmona, V. B., Simao, J. A., Galvani, F., Marconcini, J. M., & Mattoso, L. H. C. (2019). Cellulose nanocrystals from fibers of macauba (Acrocomia Aculeata) and gravata (Bromelia Balansae) from Brazilian pantanal. Polymers, 11(1785), 1–19. https://doi.org/10.3390/polym11111785

Gupta, G. K., & Shukla, P. (2020). Lignocellulosic biomass for the synthesis of nanocellulose and its eco-friendly advanced applications. Frontiers in Chemistry, 8(601256), 1–13. https://doi.org/10.3389/fchem.2020.601256

Muhamad, M., Hornsby, P., Carmichael, E., Zakaria, M., Seok, Y. B., Mohamed, S., & Sharma, S. (2019). Characterisation of cellulose nanofibres derived from chemical and mechanical treatments. MATEC Web of Conferences, 253(01002), 1–6. https://doi.org/10.1051/matecconf/201925301002

Mateo, S., Peinado, S., Morillas-Gutiérrez, F., La Rubia, M. D., & Moya, A. J. (2021). Nanocellulose from agricultural wastes Products and applications A review. Processes, 9, 1594. https://doi.org/10.3390/pr9091594

Das, D., Hussain, S., Ghosh, A., & Pal, A. (2018). Studies on cellulose nanocrystals extracted from Musa sapientum: Structural and bonding aspects. Cellulose Chemistry and Technology, 52, 1–13.

Abe, K., Iwamoto, S., & Yano, H. (2007). Obtaining cellulose nanofibers with a uniform width of 15 nm from wood. Biomacromolecules, 8(10), 3276–3278.

Abe, K., & Yano, H. (2009). Comparison of the characteristics of cellulose microfibril aggregates of wood, rice straw and potato tuber. Cellulose, 16(6), 1017–1023.

Chen, W., Yu, H., Liu, Y., Chen, P., Zhang, M., & Hai, Y. (2011). Individualization of cellulose nanofibers from wood using high- intensity ultrasonication combined with chemical pretreatments. Carbohydrate Polymers, 83(4), 1804–1811.

Siqueira, G., Abdillahi, H., Bras, J., & Dufresne, A. (2010). High reinforcing capability cellulose nanocrystals extracted from Syngonanthus nitens (Capim Dourado). Cellulose, 17(2), 289–298.

Rosa, M. F., Medeiros, E. S., Malmonge, J. A., Gregorski, K. S., Wood, D. F., Mattoso, L. H. C., & Imam, S. H. (2010). Cellulose nanowhiskers from coconut husk fibers: Effect of preparation conditions on their thermal and morphological behavior. Carbohydrate Polymers, 81(1), 83–92.

Bendahou, A., Habibi, Y., Kaddami, H., & Dufresne, A. (2009). Physico-chemical characterization of palm from phoenix dactylifera–L, preparation of cellulose whiskers and natural rubber–based nanocomposites. Journal of Biobased Materials and Bioenergy, 3(1), 81–90.

Fahma, F., Iwamoto, S., Hori, N., Iwata, T., & Takemura, A. (2011). Effect of pre-acid- hydrolysis treatment on morphology and properties of cellulose nanowhiskers from coconut husk. Cellulose, 18(2), 443–450.

Shimada, K., Fujikawa, K., Yahara, K., & Nakamura, T. (1992). Antioxidative properties of xanthan on the autoxidation of soybean oil in cyclodextrin emulsion. Journal of agricultural and food chemistry, 40(6), 945–948.

Kumar, A., Negi, Y. S., Bhardwaj, N. K., & Choudhary, V. (2012). Synthesis and characterization of methylcellulose/PVA based porous composite. Carbohydrate Polymers, 88(4), 1364–1372.

Cherian, B. M., Leão, A. L., de Souza, S. F., Thomas, S., Pothan, L. A., & Kottaisamy,. (2010). Isolation of nanocellulose from pineapple leaf fibres by steam explosion. Carbohydrate Polymers, 81(3), 720–725.

Martínez-Sanz, M., Lopez-Rubio, A., & Lagaron, J. M. (2011). Optimization of the nanofabrication by acid hydrolysis of bacterial cellulose nanowhiskers. Carbohydrate Polymers, 85(1), 228–236.

Kargarzadeh, H., Ahmad, I., Abdullah, I., Dufresne, A., Zainudin, S. Y., & Sheltami, R. M. (2012). Effects of hydrolysis conditions on the morphology, crystallinity, and thermal stability of cellulose nanocrystals extracted from kenaf bast fibers. Cellulose, 19(3), 855–866.

Sain, M., & Panthapulakkal, S. (2006). Bioprocess preparation of wheat straw fibers and their characterization. Industrial Crops and Products, 23(1), 1–8.

Ahmad, I., Mosadeghzad, Z., Daik, R., & Ramli, A. (2008). The effect of alkali treatment and filler size on the properties of sawdust/UPR composites based on recycled PET wastes. Journal of applied polymer science, 109(6), 3651–3658.

Zuluaga, R., Putaux, J. L., Cruz, J., Vélez, J., Mondragon, I., & Gañán, P. (2009). Cellulose microfibrils from banana rachis: Effect of alkaline treatments on structural and morphological features. Carbohydrate Polymers, 76(1), 51–59.

Wada, M., Heux, L., & Sugiyama, J. (2004). Polymorphism of cellulose I family: Reinvestigation of cellulose IVI. Biomacromolecules, 5(4), 1385–1391.

El-Sakhawy, M., & Hassan, M. L. (2007). Physical and mechanical properties of microcrystalline cellulose prepared from agricultural residues. Carbohydrate Polymers, 67(1), 1–10.

Mandal, A., & Chakrabarty, D. (2011). Isolation of nanocellulose from waste sugarcane bagasse (SCB) and its characterization. Carbohydrate Polymers, 86(3), 1291–1299.

Samimi, S., Maghsoudnia, N., Eftekhari, R. B., Dorkoosh, F. (2019). Lipid-based nanoparticles for drug delivery systems. In: Mohapatra, S. S., Ranjan, S., Dasgupta, N., Mishra, R. K., & Thomas, S. (Eds.) Characterization and Biology of Nanomaterials for Drug Delivery Micro and Nano Technologies. Elsevier, pp. 47–76. https://doi.org/10.1016/B978-0-12-814031-4.00003-9

Fahmy, A., Zaid, H., & Ibrahim, M. (2019). Optimizing the electrospun parameters which affect the preparation of nanofibers. Biointerface Research in Applied Chemistry, 9, 4463–4473. https://doi.org/10.33263/briac96.463473

Naresh, U., Kumar, R. J., & Naidu, K. C. B. (2019). Structural, morphological, optical, magnetic and ferroelectric properties of Ba0.2La0.8Fe2O4 nanofibers. Biointerface Research in Applied Chemistry, 9, 4243–4247. https://doi.org/10.33263/briac95.243247

Lolo, J.A., Nikmatin, S., Alatas, H., Prastyo, D.D., Syafiuddin, A(2020). Fabrication of biocomposites reinforced with natural fibers and evaluation of their physiochemical properties. Biointerface Research in Applied Chemistry,10, 5803–5808. https://doi.org/10.33263/briac104.803808.

Subagyo, A., Chafidz, A. (2018). Banana pseudo-stem fiber: preparation, characteristics, and applications. In: Jideani, A. I. O., & Anyasi, T. A. (Eds.) IntechOpen. Banana Nutrition - Function and Processing Kinetics. https://doi.org/10.5772/intechopen.82204

Vigneswaran, C., Pavithra, V., Gayathri, V., & Mythili, K. (2015). Banana fiber: Scope and value added product development. Journal of Textile and Apparel, Technology and Management, 9, 1–7.

Bello, K., Sarojini, B. K., Narayana, B., & Rao, A. (2018). A study on adsorption behavior of newly synthesized banana pseudo-stem derived superabsorbent hydrogels for cationic and anionic dye removal from effluents. Carbohydrate Polymers, 181, 605–615.

Mohapatra, D., Mishra, S., & Sutar, N. (2010). Banana and its by-product utilisation: An overview. Journal of Scientific & Industrial Research, 69, 323–329.

Jordan, W., & Chester, P. (2017). Improving the properties of banana fiber reinforced polymeric composites by treating the fibers. Procedia Engineering, 200, 283–289.

Ray, D., Nayak, L., Ammayappan, L., Shambhu, V., & Nag, D. (2013). Energy conservation drives for efficient extraction and utilization of banana fibre. International Journal of Emerging Technology and Advanced Engineering, 3, 296–310.

Pappu, A., Patil, V., Jain, S., Mahindrakar, A., Haque, R., & Thakur, V. K. (2015). Advances in industrial prospective of cellulosic macromolecules enriched banana biofibre resources: A review. International Journal of Biological Macromolecules, 79, 449–458.

Acknowledgements

The authors are grateful to Technical Education Quality Improvement Program (TEQIP-III) for providing financial assistance to carry out this work. We also like to thank the University Institute of Chemical Technology, Kavayitri Bahinabai Chaudhari North Maharashtra University Jalgaon, India.

Funding

Funding received from Technical Education Quality Improvement Program (TEQIP-II), Department of Higher Education. MHRD, India, and the reference number for that funding is F.No. 16–14/2016-TS.VII.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. All authors also read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics Approval and Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Research Involving Human and Animals Statement

None.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zope, G., Goswami, A. & Kulkarni, S. Isolation and Characterization of Cellulose Nanocrystals Produced by Acid Hydrolysis from Banana Pseudostem. BioNanoSci. 12, 463–471 (2022). https://doi.org/10.1007/s12668-022-00960-8

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12668-022-00960-8