Abstract

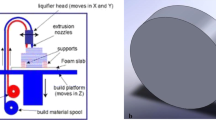

The aim of present research work is to study the effect of single particle size (SPS), dual particle size (DPS) and triple particle size (TPS) of SiC and Al2O3 reinforcement as hybrid solute on wear properties of aluminium matrix composite (AMC) prepared by stir casting in vacuum mould. The ABS plastic based master pattern (prepared with fused deposition modelling setup) for vacuum mould has been used in the present study. The friction and wear tests were carried out using a pin-on-disc type tribo-test machine under dry sliding condition. The results of study suggest that SPS based AMC exhibited better wear resistant properties as compared to DPS and TPS. The study also highlights the effect of other controllable process parameters of vacuum moulding process (namely: vacuum pressure, sand grain size and proportion of solutes) on wear behavior of AMC.

Similar content being viewed by others

References

Yao A W L, and Tseng Y C, Rapid Prototyp J 8 (2002) 180.

Lee C W , Chua C K , Cheah C M, and Tan L H, Int J Adv Manuf Technol 23 (2004) 93.

Ingole D S, Kuthe A M, Thakare S B, and Talankar A S, Rapid Prototyp J 15 (2009) 280.

Chakradeo A, and Kulkarni M A, Rapid prototyping—a tool for pre-surgical planning, in Proceeding of International conference on e-Manufacturing, Bhopal (2002) 271.

Sood A K, Ohdar R K, and Mahapatra S S, J Mater Sci 30 (2009) 4243.

Kumar P, Ahuja I P S, and Singh R, Int J Mater Eng Innov 3 (2012) 204.

Kumar S, Kumar P, and Shan H S, Mater Manuf Process 22 (2007) 879.

Singh R, J Inst Eng (India): Ser C 94 (2013) 93.

Kumar P, and Gaindhar J L, Qual Reliab Eng 11 (1995) 175.

Gaindhar J L, Jain C K, and Subbarathnanmaiah K, Trans Am Foundry men’s Soc 93 (1985) 303.

Singh R, and Singh J, Mater Sci Forum 751 (2013) 21.

Singh K, and Singh R, Appl Mech Mater 330 (2013) 91.

Skibo M D, and Schuster D M, Preparation of metal matrix composites under atmospheric pressure, U.S. Patent no. 6106588 A (2000).

Hashim J, Looney L, and Hashmi M S J, J Mater Process Technol 123 (2002) 251.

Sozhamannan G G, Prabu S B, and Venkatagalapathy V S K, J Surf Eng Mater Adv Technol 2 (2012) 11.

Singh R, Singh S, and Sahni K, Effect of double and triple particle size Al2O3 reinforcement on properties of aluminium matrix composite prepared by vacuum moulding, In: 5th International & 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014) December 12–14, IIT Guwahati, Assam, India (2014) pp. 12(1)–12(4).

Samal B P, Misra A K, Panigrahi S C, and Mishra S C, J Mater Metall Eng 3 (2013) 26.

Singh R, Singh S, and Singh S, Investigations for mechanical properties of metal matrix composite prepared by combining FDM, vacuum moulding and stir casting, 5th International & 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014) December 12–14, IIT Guwahati, Assam, India (2014) pp. 13(1)–13(5).

Acknowledgments

The authors are thankful to DST, New Delhi for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, R., Podder, D. & Singh, S. Effect of Single, Double and Triple Particle Size SiC and Al2O3 Reinforcement on Wear Properties of AMC Prepared by Stir Casting in Vacuum Mould. Trans Indian Inst Met 68, 791–797 (2015). https://doi.org/10.1007/s12666-015-0512-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-015-0512-1