Abstract

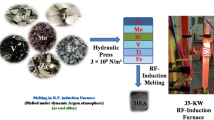

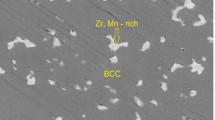

For the first time, we report here that the development of the novel Ti–Cu–Fe–Co–Ni high entropy alloys (HEAs) via vacuum arc melting technique using non consumable tungsten electrode under high purity Ar atmosphere on a water-cooled copper hearth. Ti–Cu–Fe–Co–Ni multicomponent alloys with varying Ti/Cu (x) molar ratio (x = 1/3, 3/7, 3/5, 9/11, 1, 11/9 and 3/2) have been prepared through the tailoring of microstructure to get understanding of the phase formation and the microstructural evolution of these multicomponent HEAs. X-ray diffraction and scanning electron microscopy coupled with energy dispersive spectroscopic results confirm the presence of (Cu)ss, (Co)ss and (β-Ti)ss dendrites with ultrafine eutectic between cubic (Cu)ss and Laves phase (Ti2Co type). The solidification pathways of novel alloys are critically discussed as follows. For x = 9/11, 1, 11/9 and 3/2; firstly, (β-Ti)ss dendrite is formed from the liquid, followed by the liquid phase separation between the cobalt-rich solid solution (Co)ss and copper-rich solid solution (Cu)ss and finally, the remaining liquid undergoes eutectic reaction between copper solid solution (Cu)ss and the Laves phase (Ti2Co Type), whereas for x = 1/3, 3/7 and 3/5; (β-Ti)ss dendrite is formed first from the liquid and then remaining liquid undergoes the liquid phase separation resulting two different dendrites of (Cu)ss and (Co)ss phases. Detailed thermodynamic calculations have been carried to rationalize the formation of stable solid solution phases of these newly developed multicomponent Ti–Cu–Fe–Co–Ni HEAs.

Similar content being viewed by others

References

Brandes E A and Brook G B, Smithells Metals Reference Book, 7th ed., Butterworths-Heinemann Ltd., Hartnolls Ltd., Bodmin, UK (1992)

Porter D A and Easterling K E, Phase Transformation in Metals and Alloys, 2nd ed. Nelson Thorne Ltd, Cheltenham, (2001)

Li B S, Wang Y P, Ren M X, Yang C and Fu H Z, Mater Sci Eng A 498 (2008) 482.

Cantor B, Chang I T H, Mater Sci Eng A 375–377 (2004) 213.

Inoue A and Takeuchi A, Acta Mater 59 (2011) 2243.

Yeh J W, Chen S K and Chen Y L, Frontiers in the Design of Materials, CRC Publications, Boca Raton (2007) p 31.

Yeh J W, Chen S K, Gan J Y, Chin T S, Shun T T, Tsau C H and Chang S Y, Adv Eng Mater 6 (2004) 299.

Varalakshmi S, Kamaraj M and Murty B S, Mater Sci Eng A 527 (2010) 1027.

Zhou Y J, Zhang Y, Wang Y L and Chen G L, Science 454 (2007) 260.

Zhou Y J, Zhang Y, Wang F J and Chen G L, Appl Phys Lett 92 (2008) 241917.

Zhang K B, Zhang Z Y, Zhang J Y, Wang W M, Lee S W and Niihara K, J All Comp 495 (2010) 33.

Tang W Y and Yeh J W, Metall Mater Trans A 40A (2009) 1479.

Yang X and Zhang Y, Mater Chem Phys 132 (2012) 233.

Yeh J W, Chang S Y, Hong Y D, Chen S K and Lin S J, Mater Chem Phys 103 (2007) 41.

Yeh J W, Lin S J, Chin T S, Gan J Y, Chen S K, Shun T T, Tsau C H and Chou S Y, Metall Mater Trans A 35 (2004) 2533.

Singh S, Wanderka N, Murty B S, Glatzel U, Banhart J, Acta Mater 59 (2011) 182.

Chou Y L, Yeh J W and Shih H C, Corr Sci 52 (2010) 2571.

Hsu C Y, Yeh J W, Chen S K and Shun T T, Metall Mater. Trans 35A (2004) 1465

Tong C J, Chen Y L, Chen S K, Yeh J W, Shun T T, Tsau C H, Lin S J and Chang S Y, Metall Mater Trans 36A (2005) 881.

20. Chen Y Y, Hong U T, Yeh J W and Shih H C: Appl Phys Lett, 87 (2005) 261918-1-3

Varalakshmi S, Kamaraj M and Murty B S, J All Comp 460 (2008) 253.

Praveen S, Murty B S and Kottada R S, Mater Sci Eng A 534 (2012) 83.

Varalakshmi S, Kamaraj M and Murty B S, Metall Mater Trans A 41A (2010) 2703.

Lin C H, Duh J G and Yeh J W, S Coat. Tech 201 (2007) 6304.

Lai C H, Tsai M H, Lin S J and Yeh J W, S Coat Tech 201 (2007) 6993.

Tsai M H, Lai C H, Yeh J W and Gan J Y, Appl Phys Lett 92 (2008) 052109.

Zhang H, Pan Y and He Y Z, Mater Design 32 (2011) 1910.

Zhang Y and Zhou Y J, Mater Sci Forum 561–565 (2007) 1337.

29. Zhang Y, Zhou Y J, Lin J P, Chen G L and Liaw P K, Adv Eng Mater 10 (2008) 534.

Takeuchi A and Inoue A, Mater Trans JIM 41 (2000) 1372.

Takeuchi A and Inoue A, Mater Trans JIM 46 (2005) 2817.

Takeuchi A and Inoue A, Mater Sci Eng A 304–306 (2001) 446.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mishra, A.K., Samal, S. & Biswas, K. Solidification Behaviour of Ti–Cu–Fe–Co–Ni High Entropy Alloys. Trans Indian Inst Met 65, 725–730 (2012). https://doi.org/10.1007/s12666-012-0206-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-012-0206-x