Abstract

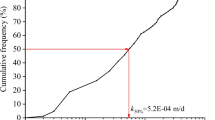

Groundwater-sealed liquid propane storage cavern is usually built in crystalline rock mass. Water curtain system is an indispensable facility to ensure the containment efficiency of the cavern due to the strong heterogeneity of fractured rock mass and the special properties of stored product. In this study, a propane cavern in Yantai, Shandong province is selected as a study case to investigate the reasonable water curtain pressure. Stochastic mathematical method was applied to calculate the permeability coefficient of the study area. A vertical 2D three-phase flow model based on THOUGH2 is established to study the migration characteristics of the stored product under different water curtain pressure and the influence of water curtain pressure on the gas containment of the cavern. It was found that the leakage of stored product can be restrained effectively when the water curtain pressure is greater than or equal to 0.8 MPa. When the water curtain is greater than or equal to 1.2 MPa, part of water in the water curtain is discharged from the simulation area, which will reduce the utilization rate of water resources and increase the operating cost. Therefore, the reasonable range of horizontal water curtain pressure is 0.8~1.1 MPa under this case or similar condition. The geological conditions and the migration characteristics of stored product considered in this paper, and the reasonable range of water curtain pressure obtained as well, can provide a new reference and methodology for the optimum determination of water curtain pressure in groundwater-sealed cavern engineering to increase the efficiency and reduce the cost of the work.

Similar content being viewed by others

References

Åberg B (1978) Prevention of gas leakage from unlined reservoir in rock[J]. Storage Excav Rock Caverns 2:399–413

Chung IW, Cho WC, Heo JH (2003) Stochastic hydraulic safety factor for gas containment in underground storage caverns. J Hydrol 284:77–91

Jun WU, Tan YJ, Deng HZ et al (2007) Heterogeneity of scale free network. Syst Eng Theory Pr 27(5):101–105

Kim J, Cho W, Chung IM et al (2007) On the stochastic simulation procedure of estimating critical hydraulic gradient for gas storage in unlined rock caverns. Geosci J 11(3):249–258

Komada H, Nakagawa K, Kitahara Y et al (1981) Study on seepage flow through rock mass surrounding caverns for petroleum storage. Subsurf Space 1:303–310

Lee Sangpil (2005) A study on the quantitative analysis for the gas tightness of LPG underground storage facilities. J Korean Soc Miner Energy Resour Eng 42(4):345–353

Li ZK, Wang KZ, Wang AM et al (2009) Experimental study of water curtain performance for gas storage in an underground cavern. J Rock Mech Geotech Eng 1(1):89–96

Li SC, Wang ZC, Yang P et al (2014) Discrete element analysis of hydro-mechanical behavior of a pilot underground crude oil storage facility in granite in China. Tunn Undergr Space Technol 40:75–84

Liang J, Lindblom U (1994) Analyses of gas storage capacity in unlined rock caverns. Rock Mech Rock Eng 27(3):115–134

Lin F, Ren F, Luan HB et al (2016) Effectiveness analysis of water-sealing for underground LPG storage. Tunn Undergr Space Technol 51:270–290

Pruess K (2004) The TOUGH codes—a family of simulation tools for multiphase flow and transport processes in permeable media[J]. Vadose Zone J 3(3):738–746

Pruess K, Battistelli A (2003) TMVOC, simulator for multiple volatile organic chemicals[C]//Tough Symposium, 2003

Pruess K, Oldenburg CM, Moridis GJ (1999) TOUGH2 user’s guide, 2nd edn. Lawrence Berkeley National Laboratory, California

Rehbinder G, Karlsson R, Dahlkild A (1988) A study of a water curtain around a gas store in rock. Appl Sci Res 45(2):107–127

Seung HR, Won MS (1999) An analysis of gas tightness around unlined storage cavern using a discrete fracture flow FEM model. Geosystem Eng 2(2):61–67

Shi HB (2010) Analysis and evaluation of water seal condition and surrounding rock stability for Huangdao water sealed underground petroleum storage caverns in rock. Beijing Jiaotong University, Beijing (in Chinese)

Sun JP, Zhao ZY (2010) Effects of anisotropic permeability of fractured rock masses on underground oil storage caverns. Tunn Undergr Space Technol 25:629–637

Wang ZL (2012) The Permeable field characteristics of fractured rock mass in Yantai Wanhua underground water-sealing (LPG) storage caverns: anisotropy, spatial variability and sequential indicator simulation. China University of Geosciences, Wuhan (in Chinese)

Wang JK, Wu ZY et al (2014) Necessity of water curtain for water-sealed underground oil storage cavern. J Yangtze River Sci Res Inst 31(1):110–113 (in Chinese)

Yamamoto H, Pruess K (2004) Numerical simulations of leakage from underground LPG storage caverns. Lawrence Berkeley National Laboratory, University of California, Berkeley, Berkeley

Yang DW, Kim DS (1998) Preliminary study for determining water curtain design factor by optimization technique in underground energy storage. Int J Rock Mech Min Sci 35(4):409–514

Zhang ZG, Tan ZS, Wan JL, Zhang HR (2003) Three-dimensional seepage analysis of underground LPG storage with water curtain. Chin J Geotech Eng 25(3):331–335 (in Chinese)

Zhong KL, Wang KZ, Wang AM et al (2009) Experimental study of water curtain performance for gas storage in an underground cavern. J Rock Mech Geotech Eng 1(1):89–96

Acknowledgements

This research was supported by an Integrative Study Program on Groundwater-sealed LPG storage caverns engineering from China Petroleum Engineering & Construction Corporation (East China Design Branch).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is a part of a Topical Collection in Environmental Earth Sciences on Water Resources and Hydraulic Engineering, guest edited by Drs. Yanqing Lian, Walton Kelly, and Fulin Li.

Rights and permissions

About this article

Cite this article

Hu, C., Chen, G., Yang, R. et al. A case study on optimum identification of water curtain hydraulic pressure using three-phase flow numerical simulation. Environ Earth Sci 78, 300 (2019). https://doi.org/10.1007/s12665-019-8278-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-019-8278-0