Abstract

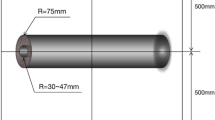

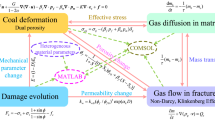

The excavation and drainage drilling for underground mining induces stress redistribution around the gas drainage borehole, thus forming three physical zones: residual state zone, strain softening zone and elastic zone. The formation process of these zones contains complex interactions among deformation, natural gas flow, and coal seam damage. A better understanding of these interactions could provide better guidance for the gas drainage engineering. Extensive studies have focused on the effect of effective stress or effective strain on permeability variation based on the poroelastic theory. Meanwhile, as there is few permeability models taking the post-peak failure effect into account, previous permeability variation analysis seldom commonly considered the elastoplastic characteristic of coal seam, which results in the permeability misestimation. Therefore, this study proposes a new approach to analyze this interaction process. The innovation of this approach is that it takes into account the influence of coal permeability enhancement in failure zone and the volumetric compaction in elastic zone around the drainage borehole. In this approach, analytical solutions of stress and strain are developed to include both the strain softening around a gas drainage borehole and the compaction in elastic zone. These solutions thus remove the flaws that previous studies did not consider the compaction in elastic zone. Further, a new permeability model is proposed by the introduction of damage enhancement coefficient for post-peak failure. Third, the permeability distribution of coal around a gas drainage borehole is calculated based on the analytical solutions and the new permeability model. Fourth, the gas flow equation is numerically solved to obtain gas pressure profiles. The gas content computed by this approach is verified by field data. Finally, parametric study is carried out to investigate the effect of the damage enhancement coefficient, initial geo-stress, drilling volume, and uniaxial strength on the gas pressure and the permeability around the gas drainage borehole. Based on these numerical analyses, it is found that the evolution of permeability is closely related to the physical properties of coal and the geological condition of coal seam. Higher initial geo-stress and lower failure strength have larger unloading zone and higher permeability enhancement. This compaction helps the coal seam form a flow-shielding zone near the interface between plastic zone and elastic zone. The gas flow in the coal around the drainage borehole can be divided into four different zones.

Similar content being viewed by others

Abbreviations

- R 0, R b, R p :

-

Radii of the borehole, residual state zone and strain softening zone (m)

- \(\sigma _{\theta }^{{\text{p}}}\), \(\sigma _{{\text{r}}}^{{\text{p}}}\) :

-

Hoop and radial stress components in the strain-softening zone (MPa)

- \({m_{\text{e}}}\), \({m_{\text{p}}}\), \({m_{\text{b}}}\) :

-

Dilatation coefficients in the elastic zone, the strain-softening zone and the residual state zone (–)

- \(\sigma _{{\text{c}}}^{*}\) :

-

Uniaxial residual strength (MPa)

- \({\sigma _{{R_{\text{p}}}}}\) :

-

Stress on the boundary between the strain-softening zone and the elastic zone (MPa)

- \(\Delta \varepsilon _{\theta }^{{}}\) :

-

Increments of hoop strain (–)

- \(E\) :

-

Young’s modulus of coal (MPa)

- \({p_{\text{i}}}\) :

-

Initial geo-stress (MPa)

- \(\alpha\) :

-

Biot coefficient (–)

- \(b\) :

-

Fracture aperture (m)

- \(\tau\) :

-

Tortuosity parameter (–)

- \(\gamma\) :

-

Mutation coefficient (–)

- \(\lambda\) :

-

Damage enhancement coefficient (–)

- \({\vec {q}_{\text{g}}}\) :

-

Velocity (m/s)

- \({\nu ^{\text{b}}}\) :

-

Volumetric strain in the residual state zone (–)

- p :

-

Gas pressure (MPa)

- \({Q_{\text{m}}}\) :

-

Gas source by injection (m3/s)

- \({\rho _{{\text{ga}}}}\) :

-

Gas density at standard conditions (kg/m3)

- \({\rho _{\text{c}}}\) :

-

Density of coal (kg/m3)

- \({V_{{\text{sg}}}}\) :

-

Content of absorbed gas

- K :

-

Bulk modulus of coal (MPa)

- \({k_{\text{g}}}\) :

-

Permeability of coal (m2)

- ϕ 0 :

-

Initial porosity (–)

- k 0 :

-

Initial permeability (m2)

- \(\sigma _{\theta }^{{\text{e}}}\), \(\sigma _{{\text{r}}}^{{\text{e}}}\) :

-

Hoop and radial stress components in the elastic zone (MPa)

- \(\sigma _{\theta }^{{\text{b}}}\), \(\sigma _{{\text{r}}}^{{\text{b}}}\) :

-

Hoop and radial stress components in the residual state zone (MPa)

- \({\nu ^{\text{e}}}\), \({\nu ^{\text{p}}}\), \({\nu ^{\text{b}}}\) :

-

Volumetric strain in elastic zone, the strain-softening zone and the residual state zone (–)

- \(\sigma _{{\text{c}}}^{{\text{p}}}\) :

-

Uniaxial compressive strength (MPa)

- \({R_{\text{p}}}\) :

-

Boundary between the strain-softening zone and the elastic zone (m)

- \(\Delta {\varepsilon _{\text{r}}}\) :

-

Increments of radial strain (–)

- \({p_{\text{s}}}\) :

-

Supporting traction of cavity (MPa)

- \({k_{\text{s}}}\) :

-

Softening coefficient of coal (–)

- \({K_{\text{p}}}\) :

-

Modulus of pores (MPa)

- \({l_{\text{n}}}\) :

-

Sum of the lengths of the multi-fractures (m)

- \(\Delta p\) :

-

Pressure difference (MPa)

- \({c_{\text{f}}}\) :

-

Compression coefficient of fracture (MPa−1)

- \({\sigma _{\text{e}}}\) :

-

Effective stress (MPa)

- V L :

-

Adsorption capacity of coal (m3/kg)

- P L :

-

Langmuir pressure constant (MPa)

- \({\varepsilon _{\text{s}}}\) :

-

Sorption-induced volumetric strain (–)

- m :

-

Mass content (kg/m3)

- ρ g :

-

Density of CH4 at standard condition (kg/m3)

- \({p_0}\) :

-

Initial gas pressure (MPa)

- K s :

-

Bulk modulus of coal grains (MPa)

- t :

-

Time (s)

- \(\phi\) :

-

Coal porosity (–)

- \(\mu\) :

-

Gas dynamic viscosity (Pa s)

- \(\varphi\) :

-

Internal friction angle of coal (°)

References

Adhikary DP, Guo H (2015) Modelling of longwall mining-induced strata permeability change. Rock Mech Rock Eng 48(1):345–359

Alonso E, Alejano LR, Varas F, Fdez-Manin G, Carranza-Torres C (2003) Ground response curves for rock masses exhibiting strain–softening behaviour. Int J Numer Anal Methods Geomech 27(13):1153–1185

Booth P, Brown H, Nemcik J, Ren T, Civil SO (2017) Spatial context in the calculation of gas emissions for underground coal mines. Int J Min Sci Technol 27(5):787–794

Borisenko AA (1985) Effect of gas pressure on stresses in coal strata. J Min Sci 21:88–92

Brown ET, Bray JW, Ladanyi B, Hoek E (1983) Ground response curves for rock tunnels. J Geotech Eng 109(1):15–39

Carranza-Torres C (2004) Elasto–plastic solution of tunnel problems using the generalized form of the Hoek–Brown failure criterion. Int J Rock Mech Min Sci 41:629–639

Chen HD, Cheng YP, Zhou HX, Li W (2013) Damage and permeability development in coal during unloading. Rock Mech Rock Eng 46(6):1377–1390

Chen D, Pan Z, Shi JQ, Si G, Ye Z, Zhang J (2016) A novel approach for modelling coal permeability during transition from elastic to post-failure state using a modified logistic growth function. Int J Coal Geol 163(1):132–139

Chu T, Jiang D, Minggao YU (2017) Experimental study of the seepage properties of the compacted particle coal under gradual loading. J China Univ Min Technol 46(5):1058–1065

Clarkson CR, Jordan CL, Geirhart RR, Seidle JP (2007) Production data analysis of CBM wells. In: SPE 107705, presented at the SPE rocky mountain oil and gas technology symposium, April 15–17, Denver

Cui X, Bustin RM (2005) Volumetric strain associated with methane desorption and its impact on coalbed gas production from deep coal seams. AAPG Bull 89(9):1181–1202

Gilman A, Beckie R (2000) Flow of coal–bed methane to a gallery. Transp Porous Media 41(1):1–16

Guan Z, Jiang Y, Tanabasi Y (2007) Ground reaction analyses in conventional tunnelling excavation. Tunn Undergr Space Technol 22(2):230–237

Hu QT, Zhang ST, Wen GC, Dai LC, Wang B (2015a) Coal–like material for coal and gas outburst simulation tests International. J Rock Mech Min Sci 74:151–156

Hu S, Zhou F, Liu Y, Xia T (2015b) Effective stress and permeability redistributions induced by successive roadway and borehole excavations. Rock Mech Rock Eng 48(1):319–332

Jin HW, Hu QT, Liu YB (2011) Failure mechanism of coal and gas outburst initiation. Proc Eng 26:1352–1360

Karacan C (2007) Development and application of reservoir models and artificial neural networks for optimizing ventilation air requirements in development mining of coal seams. Int J Coal Geol 72(3):221–239

Li CW, Fu S, Cui YG, Sun XY, Xie BJ, Yang W (2017) Study of the migration rule of high-concentration gas and spatial-temporal feature of gas hazard in the tunnel. J China Univ Min Technol 46(1):27–32

Lin BQ, Yang W, Wu HJ, Meng FW, Zhao YX, Zhai C (2010) A numeric analysis of the effects different factors have on slotted drilling. J China Univ Min Technol 39(2):153–157

Liu YB, Cao SG, Li Y, Wang J, Guo P, Xu J, Bai YJ (2010) Experimental study of swelling deformation effect of coal induced by gas adsorption. Chin J Rock Mech Eng 29(12):2485–2491

Liu Q, Cheng Y, Zhou H, Guo P, An F, Chen H (2015) A mathematical model of coupled gas flow and coal deformation with gas diffusion and Klinkenberg effects. Rock Mech Rock Eng 48(3):1163–1180

Liu T, Lin B, Yang W, Liu T, Zhai C (2017) An integrated technology for gas control and green mining in deep mines based on ultra-thin seam mining. Environ Earth Sci 76(6):243

Lu YE, Yang W (2013) Analytical solutions of stress and displacement in strain softening rock around a newly formed cavity. J Central South Univ 20:1397–1404

Men XX, Tang CA, Han ZH (2014) Numerical simulation on propagation mechanism of hydraulic fracture in fractured rockmass. Appl Mech Mater 488–489:417–420

Palmer I, Mansoori J (1996) How permeability depends on stress and pore pressure in coalbeds: a new model. In: 1996 SPE annual technical conference and exhibition society of petroleum engineers, Inc, Denver

Pan Z, Connell LD (2011) Modelling of anisotropic coal swelling and its impact on permeability behaviour for primary and enhanced coalbed methane recovery. Int J Coal Geol 85(3):257–267

Pan RK, Cheng YP, Yuan L, Yu MG, Dong J (2014) Effect of bedding structural diversity of coal on permeability evolution and gas disasters control with coal mining. Nat Hazards 73(2):1086–1092

Peng R, Ju Y, Wang JG, Xie H, Gao F, Mao L (2015) Energy dissipation and release during coal failure process in conventional triaxial compression. Rock Mech Rock Eng 48:509–526

Qu H, Liu J, Pan Z, Connell L (2014) Impact of matrix swelling area propagation on the evolution of coal permeability under coupled multiple processes. J Nat Gas Sci Eng 18:451–466

Saghafi A, Faiz M, Roberts D (2007) CO2 storage and gas diffusivity properties of coals from Sydney Basin, Australia. Int J Coal Geol 70(1):240–254

Salmachi A, Karacan C (2017) Cross-formational flow of water into coalbed methane reservoirs: controls on relative permeability curve shape and production profile. Environ Earth Sci 76(5):200

Salmachi A, Yarmohammadtooski Z (2015) Production data analysis of coalbed methane wells to estimate the time required to reach to peak of gas production. Int J Coal Geol 141:33–41

Salmachi A, Sayyafzadeh M, Haghighi M (2013) Infill well placement optimization in coal bed methane reservoirs using genetic algorithm. Fuel 111(18):248–258

Salmachi A, Rajabi M, Reynolds P, Yarmohammadtooski Z, Wainman C (2016) The effect of magmatic intrusions on coalbed methane reservoir characteristics: a case study from the Hoskissons coalbed, Gunnedah Basin, Australia. Int J Coal Geol 165:278–289

Shi JQ, Durucan S (2004) Drawdown induced changes in permeability of coalbeds: a new interpretation of the reservoir response to primary recovery. Transp Porous Media 56(1):1–16

Singh AK, Singh R, Maiti J, Kumar R, Mandal PK (2011) Assessment of mining induced stress development over coal pillars during depillaring. Int J Rock Mech Min Sci 48:805–818

State Administration of Coal Mine Safety of China (2006) Cord for coal mine gas drainage China standard, Beijing

Tang CA, Tham LG, Lee PKK, Yang TH, Li LC (2002) Coupled analysis of flow, stress and damage (FSD) in rock failure. Int J Rock Mech Min Sci 39(4):477–489

Wang S, Elsworth D, Liu J (2013) Permeability evolution during progressive deformation of intact coal and implications for instability in underground coal seams. Int J Rock Mech Min Sci 58:34–45

Xue Y, Gao F, Gao Y, Cheng H, Liu Y, Hou P, Teng T (2016) Quantitative evaluation of stress-relief and permeability-increasing effects of overlying coal seams for coal mine methane drainage in Wulan coal mine. J Nat Gas Sci Eng 32:122–137

Xue Y, Gao F, Liu X, Liang X (2017) Permeability and pressure distribution characteristics of the roadway surrounding rock in the damaged zone of an excavation. Int J Min Sci Technol 27(2):211–219

Xue Y, Dang F, Shi F, Li R, Cao Z (2018) Evaluation of gas migration and rock damage characteristics for underground nuclear waste storage based on a coupled model. Sci Technol Nucl Installations 2018:2973279. https://doi.org/10.1155/2018/2973279

Yang XJ, Baleanu D (2013) Fractal heat conduction problem solved by local fractional variation iteration method. Therm Sci 17(2):625–628

Yang XL, Huang F (2010) Influences of strain softening and seepage on elastic and plastic solutions of circular openings in nonlinear rock masses. J Central South Univ Technol 17:621–627

Yarmohammadtooski Z, Salmachi A, White A, Rajabi M (2017) Fluid flow characteristics of Bandanna Coal Formation: a case study from the Fairview Field, eastern Australia. Aust J Earth Sci 64(3):319–333

Yin GZ, Jiang CB, Wang JG, Xu J (2013) Combined effect of stress, pore pressure and temperature on methane permeability in anthracite coal: an experimental study. Transp Porous Media 100(1):1–16

Yin GZ, Jiang CB, Wang JG, Xu J (2015) Geomechanical and flow properties of coal from loading axial stress and unloading confining pressure tests. Int J Rock Mech Min Sci 76:155–161

Yuan WB, Chen J (1986) Analysis of plastic zone and loose zone around opening in softening rock. J China Coal Soc 11(3):77–86

Zhang C, Wang J, Zhao J (2010) Unified solutions for stresses and displacements around circular tunnels using the unified Strength. Theory Sci China (Technological Sciences) 53(6):1694–1699

Zhu WC, Wei CH, Liu J, Xu T, Elsworth D (2013) Impact of gas adsorption induced coal matrix damage on the evolution of coal permeability. Rock Mech Rock Eng 46(6):1353–1366

Zhu WC, Gai D, Wei CH, Li SG (2016) High-pressure air blasting experiments on concrete and implications for enhanced coal gas drainage. J Nat Gas Sci Eng 36:1253–1263

Zhu W, Liu L, Liu J, Wei C, Peng Y (2018) Impact of gas adsorption-induced coal damage on the evolution of coal permeability. Int J Rock Mech Min Sci 101:89–97

Acknowledgements

This study is sponsored by the National Natural Science Foundation of China (no. 51679199), the China Postdoctoral Science Foundation (no. 2018M633549), the Special Funds for Public Industry Research Projects of the Ministry of Water Resources (no. 201501034-04 and 201201053-03), Initiation Fund of Doctor’s Research (no. 107-451117008) and the Key Laboratory for Science and Technology Coordination & Innovation Projects of Shaanxi Province (no. 2014SZS15-Z01).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xue, Y., Dang, F., Liu, F. et al. An elastoplastic model for gas flow characteristics around drainage borehole considering post-peak failure and elastic compaction. Environ Earth Sci 77, 669 (2018). https://doi.org/10.1007/s12665-018-7855-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-018-7855-y