Abstract

Purpose

Present study aims to use oil palm frond (OPF) hydrolysate obtained from enzymatic hydrolysis as feedstock for ethanol production.

Methods

Pretreated OPF was used in this study. Optimization of ethanol production was performed using central composite design of response surface methodology. TAPPI Standard Methods were used to analyze the chemical composition of the pretreated OPF.

Results

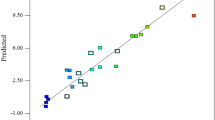

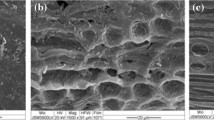

The results obtained indicated that the biomass contains 63.68% of cellulose, 21.92% of hemicellulose and 14.4% of lignin content. Enzymatic hydrolysis of pretreated OPF showed that the highest reducing sugar of 2444.6 µg/g was obtained when the biomass was hydrolysed using cellulase (40 U/g) and hemicellulase (10 U/g) for 150 min at 50 °C. The kinetic study indicated that the specific growth rate of S. cerevisiae HC10 during ethanol production was 0.034 h−1 with about 20.39 h of doubling time. The biomass yield coefficient and ethanol yield coefficient obtained were 0.1623 g cell/g sugar and 0.1191 g ethanol/g sugar, respectively. The highest ethanol yield was 79.4%. Fermentation profile for ethanol production demonstrated that the highest ethanol (7.23 g/L) was detected at 24 h of fermentation process. Under optimized conditions of inoculum, 30 mL; hydrolysate, 78.85 mL; pH, 4.50; and incubation time, 94.01 h, the highest ethanol yield was 13.79 g/L.

Conclusions

The results obtained from this study proved that OPF hydrolysate obtained from enzymes hydrolysis has high potential to be used as feedstock for ethanol production.

Similar content being viewed by others

References

Fasahati, P., Woo, H.C., Liu, J.J.: Industrial-scale bioethanol production from brown algae: effects of pretreatment processes on plant economics. Appl. Energy 139, 175–187 (2015)

Chaturvedi, V., Verma, P.: An overview of key pretreatment process employed for bioconversion of lignocellulosic biomass into biofuels and value-added products. Biotech 3, 415–431 (2013)

Lee, R.A., Lavoie, J.M.: From first- to third-generation biofuels: challenges of producing a commodity from a biomass of increasing complexity. Anim. Front. 3, 6–11 (2013)

Brennan, L., Owende, P.: Biofuels from microalgae—a review of technologies for production, processing, and extractions of biofuels and co-products. Renew. Sustain. Energy Rev. 14, 557–577 (2010)

Aro E.-M.: From first-generation biofuels to advanced solar biofuels. Ambio, 45 (Suppl. 1), 24–31 (2016)

Lorestani, A.A.Z.: Biological treatment of palm oil effluent (POME) using an up-flow anaerobic sludge fixed film (UASFF) bioreactor. Doctoral dissertation, Universiti Sains Malaysia (2006)

Abdullah, N., Sulaiman, F.: The oil palm wastes in Malaysia. In: Matovic, M.D. (ed.) Biomass Now-sustainable Growth and Use. Science, Technology, and Medicine open access publisher (2013)

Jamaludin, N.F.M.: Study on bioethanol production from oil palm trunk (OPT) sap by using Saccharomyces Cerevisiae Kyokai No.7 (ATCC 26422). Bachelor of Chemical Engineering (Biotechnology), Universiti Malaysia Pahang (2010)

Lim, S.H., Ibrahim, D., Che Omar, I.: Oil palm frond for the production of bioethanol. Int. J. Biochem. Biotechnol. 1, 007–011 (2012)

Crawford, Don, L., Ronald, L.: Crawford.: Microbial degradation of lignocellulose: the Lignin Component. Appl. Environ. Microbiol. 31(5), 714–717 (1976)

Subramaniyam, R., Vimala, R.: Solid State and submerged fermentation for the production of bioactive substances: a comparative study. Int. J. Sci. Nat. 3, 480–486 (2012)

Dombek, K.M., Ingram, L.O.: Ethanol production during batch fermentation with Saccharomyces cerevisiae: changes in glycolytic enzymes and internal pH. Appl. Environ. Microbiol. 53(6), 1286–1291 (1987)

Stanbury, P.F.: Principles of Fermentation Technology, Pergamon Press, UK Ch.1 (1984)

Mukhtar, Z.: Biological pretreatment of oil palm frond (OPF) for a better yield of fermentable sugar. Undergraduate Dissertation, Universiti Sains Malaysia (2015)

Dubois, M., Gilles, K.A., Hamilton, J.K., Rebers, P.A., Smith, F.: Colorimetric method for determination of sugars and related substances. Anal. Chem. 28, 350–356 (1956)

Miller, G.L.: Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 31, 426–428 (1959)

Maurice, M.L.: Factors effecting ethanol fermentation via simultaneous saccharification and fermentation. Doctoral dissertation, Shanghai Jiao Tong University (2011)

Abdul Halim, F.A.: Oil palm frond juice: potential feedstock for bioethanol production. Undergraduate Dissertation, Universiti Sains Malaysia (2014)

Behera, S.S., Ray, R.C.: Solid state fermentation for production of microbial cellulases: recent advances and improvement strategies. Int. J. Biol. Macromol. 86, 656–669 (2016)

Sun, Y., Cheng, J.Y.: Hydrolysis of lignocellulosic materials for ethanol production: a review. Bioresour. Technol. 83, 1–11 (2002)

Lin, Z.X., Huang, H., Zhang, H.M., Zhang, L., Yan, L.S., Chen, J.W.: Ball milling pretreatment of corn stover for enhancing the efficiency of enzymatic hydrolysis. Appl. Biochem. Biotechnol. 162, 1872–1880 (2010)

Tye, Y.Y., Lee, K.T., Wan Abdullah, W.N., Leh C.P.: Potential of Ceiba pentandra (L.) Gaertn. (kapok fiber) as a resource for second generation bioethanol: effect of various simple pretreatment methods on sugar production. Bioresour. Technol. 116, 536–539 (2012)

Zhang, X.Y., Yu, H.B., Huang, H.Y., Liu, Y.X.: Evaluation of biological pretreatment with white rot fungi for the enzymatic hydrolysis of bamboo culms. Int. Biodeterior. Biodegrad. 60, 159–164 (2007)

Winkelhausen, E., Velickova, E., Amartey, S. A., Kuzmanova, S.: Ethanol production using immobilized Saccharomyces cerevisiae in lyophilized cellulose gel. Appl. Biochem. Biotechnol. 162, 2214–2220 (2010)

Gibson, B.R, Lawrence, S.J., Leclaire, J.P, Powell, C.D., Smart, K.A.: Yeast responses to stresses associated with industrial brewery handling. FEMS Microbiol. Rev. 31, 535–569 (2007)

Lee, C.K., Abdul Halim, F.A.: Oil palm frond juice: a potential feedstock for bioethanol production. Int. J. Sci. Res. Publ. 4(12), 520–526 (2014)

Maya Emira, M.S.: Production of bioethanol by Saccharomyces cerevisiae HC10 using oil palm frond juice (OPFJ). Undergraduate Dissertation, Universiti Sains Malaysia (2015)

Boender, L.G., De Hulster, E.A., Van Maris, A.J., Daran-Lapujade, P.A., Pronk, J.T.: Quantitative physiology of Saccharomyces cerevisiae at near-zero specific growth rates. Appl. Environ. Microbiol. 75, 5607–5614 (2009)

Kartawiria, I.S., Syamsub, K., Noorb, E., Sa’idb, E.: Sorghum talk Juice pre-treatment method for bioethanol fermentation process. Energy Proc. 65, 140–145 (2015)

Paredes-López, O., Camargo-Rubio, E., Ornelas-Vale, A.: Influence of specific growth rate on biomass yield, productivity, and composition of Candida utilis in batch and continuous culture. Appl Environ Microbiol. 31(4), 487–491 (1976)

Brock, T.D.: Microbial growth rates in nature. Bacteriol. Rev. 35(1), 39–58 (1971)

Estela-Escalante, W.R.M., Melzoch, K., Hatta-Sakoda, B.: Effect of aeration on the fermentative activity of Saccharomyces cerevisiae cultured in apple juice. Revista Mexicana de Ingeniería Química. 11, 211–226 (2012)

Cheng, N.G., Hasan, M., Kumoro, A.C.: Production of ethanol by fed-batch fermentation. J Sci. Technol. 17, 399–408 (2009)

Chen, M.H., Kaur, P., Dien, B., Below, F., Vincent, M.L., Singh, V.: Use of tropical maize for bioethanol production. World J. Microbiol. Biotechnol. 29, 1509–1515 (2013)

Acknowledgements

The authors would like to thank Universiti Sains Malaysia for providing short-term grant (304/PTEKIND/6312113). Special thanks to staffs of School of Industrial Technology, especially the laboratory assistant namely Mr. Azmaizan Yaakob and Mrs. Najmah Hamid. They have been very helpful in giving equipment assistance and providing for all my laboratory needs.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Farah Amani, A.H., Toh, S.M., Tan, J.S. et al. The Efficiency of Using Oil Palm Frond Hydrolysate from Enzymatic Hydrolysis in Bioethanol Production. Waste Biomass Valor 9, 539–548 (2018). https://doi.org/10.1007/s12649-017-0005-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-017-0005-z