Abstract

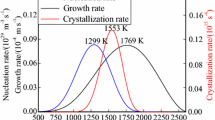

Chromium plays a vital role in stainless steel due to its ability to improve the corrosion resistance of the latter. However, the release of chromium from stainless steel slag (SSS) during SSS stockpiling causes detrimental environmental issues. To prevent chromium pollution, the effects of iron oxide on crystallization behavior and spatial distribution of spinel were investigated in this work. The results revealed that FeO was more conducive to the growth of spinels compared with Fe2O3 and Fe3O4. Spinels were found to be mainly distributed at the top and bottom of slag. The amount of spinel phase at the bottom decreased with the increasing FeO content, while that at the top increased. The average particle size of spinel in the slag with 18wt% FeO content was 12.8 µm. Meanwhile, no notable structural changes were observed with a further increase in FeO content. In other words, the spatial distribution of spinel changed when the content of iron oxide varied in the range of 8wt% to 18wt%. Finally, less spinel was found at the bottom of slag with a FeO content of 23wt%.

Similar content being viewed by others

References

Q. Zhao, C.J. Liu, X.H. Mei, H. Saxén, and R. Zevenhoven, Research progress of steel slag-based carbon sequestration, Fundam. Res., 2022. https://doi.org/10.1016/j.fmre.2022.09.023

J. Xiong, Y.L. Tong, J.L. Peng, and S.H. Zhang, Strength–toughness improvement of 13Cr4NiMo martensitic stainless steel with thermal cyclic heat treatment, J. Iron Steel Res. Int., 30(2023), No. 8, p. 1499.

C.Q. Wang, J. Li, H. Yang, and C.R. Li, Feasibility analysis of industrial waste acid treatment of stainless steel smelting slag, Mod. Metall., 38(2010), No. 1, p. 1.

X. Zhang, M. Zhang, and M. Guo, Advances and trends in high-temperature modification-crystallization control detoxification of stainless steel slag, Chin. J. Eng., 45(2023), No. 4, p. 577.

L.H. Cao, C.J. Liu, Q. Zhao, and M.F. Jiang, Analysis on the stability of chromium in mineral phases in stainless steel slag, Metall. Res. Technol., 115(2018), No. 1, art. No. 114.

Y.M. Li, Q. Zhao, X.H. Mei, C.J. Liu, H. Saxén, and R. Zevenhoven, Effect of Ca/Mg molar ratio on the calcium-based sorbents, Int. J. Miner. Metall. Mater., 30(2023), No. 11, p. 2182.

K. Pillay, H. von Blottnitz, and J. Petersen, Ageing of chromium(III)-bearing slag and its relation to the atmospheric oxidation of solid chromium(III)-oxide in the presence of calcium oxide, Chemosphere, 52(2003), No. 10, p. 1771.

W.L. Li and X.X. Xue, Effect of cooling regime on phase transformation and chromium enrichment in stainless-steel slag, Ironmaking Steelmaking, 46(2019), No. 7, p. 642.

Q. Zhao, K. Liu, L.F. Sun, et al., Towards carbon sequestration using stainless steel slag via phase modification and co-extraction of calcium and magnesium, Process. Saf. Environ. Prot., 133(2020), p. 73.

Q.Q. Mou, J.L. Li, Q. Zeng, and H.Y. Zhu, Effect of Fe2O3 on the size and components of spinel crystals in the CaO-SiO2-MgO-Al2O3-Cr2O3 system, Int. J. Miner. Metall. Mater., 26(2019), No. 9, p. 1113.

H.T. Shen and E. Forssberg, An overview of recovery of metals from slags, Waste Manage., 23(2003), No. 10, p. 933.

F. Kukurugya, P. Nielsen, and L. Horckmans, Up-concentration of chromium in stainless steel slag and ferrochromium slags by magnetic and gravity separation, Minerals, 10(2020), No. 10, art. No. 906.

M. Tossavainen, F. Engstrom, Q. Yang, et al., Characteristics of steel slag under different cooling conditions, Waste Manage., 27(2007), No. 10, p. 1335.

F. Engström, D. Adolfsson, Q. Yang, C. Samuelsson, and B. Björkman, Crystallization behaviour of some steelmaking slags, Steel Res. Int., 81(2010), No. 5, p. 362.

Z.J. Wang and I. Sohn, Understanding the solidification and leaching behavior of synthesized Cr-containing stainless steel slags with varying Al2O3/SiO2 mass ratios, Ceram. Int., 47(2021), No. 8, p. 10918.

Z.J. Wang and I. Sohn, Immobilizing chromium in stainless steel slags with MnO addition, J. Am. Ceram. Soc., 104(2021), No. 2, p. 697.

Y.M. Zhang, L.Y. Yi, L.N. Wang, et al., A novel process for the recovery of iron, titanium, and vanadium from vanadium-bearing titanomagnetite: Sodium modification–direct reduction coupled process, Int. J. Miner. Metall. Mater., 24(2017), No. 5, p. 504.

S.K. Das, Quantitative mineralogical characterization of chrome ore beneficiation plant tailing and its beneficiated products, Int. J. Miner. Metall. Mater., 22(2015), No. 4, p. 335.

Q. Zhao, J.Y. Li, K.W. You, and C.J. Liu, Recovery of calcium and magnesium bearing phases from iron–and steelmaking slag for CO2 sequestration, Process. Saf. Environ. Prot., 135(2020), p. 81.

L.H. Cao, C.J. Liu, Q. Zhao, and M.F. Jiang, Effect of Al2O3 modification on enrichment and stabilization of chromium in stainless steel slag, J. Iron Steel Res. Int., 24(2017), No. 3, p. 258.

L. Holappa, M. Kekkonen, A. Jokilaakso, and J. Koskinen, A review of circular economy prospects for stainless steelmaking slags, J. Sustain. Metall., 7(2021), No. 3, p. 806.

L. Liu, M.L. Hu, C.G. Bai, X.W. Lü, Y.Z. Xu, and Q.Y. Deng, Effect of cooling rate on the crystallization behavior of perovskite in high titanium-bearing blast furnace slag, Int. J. Miner. Metall. Mater., 21(2014), No. 11, p. 1052.

Q. Zhao, C.J. Liu, L.H. Cao, et al., Shear-force based stainless steel slag modification for chromium immobilization, ISIJ Int., 59(2019), No. 3, p. 583.

X.R. Wu, X.M. Dong, R.T. Wang, H.H. Lu, F.B. Cao, and X.M. Shen, Crystallization behaviour of chromium in stainless steel slag: Effect of feo and basicity, J. Residuals Sci. Technol., 13(2016), Suppl. 1, p. S57.

T.X. Yu, T. Jiang, J. Wen, H.Y. Sun, M. Li, and Y. Peng, Effect of chemical composition on the element distribution, phase composition and calcification roasting process of vanadium slag, Int. J. Miner. Metall. Mater., 29(2022), No. 12, p. 2144.

S. Zhang, Y.L. Zhang, and S.W. Wu, Effects of ZnO, FeO and Fe2O3 on the spinel formation, microstructure and physico-chemical properties of augite-based glass ceramics, Int. J. Miner. Metall. Mater., 30(2023), No. 6, p. 1207.

Q. Zeng, J.L. Li, Q.Q. Mou, H.Y. Zhu, and Z.L. Xue, Effect of FeO on spinel crystallization and chromium stability in stainless steel-making slag, JOM, 71(2019), No. 7, p. 2331.

Z.J. Wang and I. Sohn, Selective elemental concentration during the solidification of stainless steel slags for increased Cr recovery with MnO addition, J. Am. Ceram. Soc., 103(2020), No. 10, p. 6012.

Z.J. Wang, J. Yang, D.A. Pan, B. Liu, J.J. Tian, and S.G. Zhang, Present state of stainless steel slag resources disposal technique, J. Iron Steel Res., 27(2015), No. 2, p. 1.

J. Diao, B. Xie, Y. Wang, and C.Q. Ji, Mineralogical characterisation of vanadium slag under different treatment conditions, Ironmaking Steelmaking, 36(2009), No. 6, p. 476.

S.W. Wu, Y.L. Zhang, and S. Zhang, Chromium enrichment in different crystalline phases of Cr-containing slag under various basicities and equilibrium temperatures, J. Iron Steel Res. Int., 29(2022), No. 9, p. 1412.

X. Lu, X.L. Huang, R.F. Wei, et al., Novel method for improving iron recovery from electric arc furnace slag: On-site hot modification, J. Iron Steel Res. Int., 29(2022), No. 8, p. 1224.

Q. Zhao, C.J. Liu, L.H. Cao, X. Zheng, and M.F. Jiang, Stability of chromium in stainless steel slag during cooling, Minerals, 8(2018), No. 10, art. No. 445.

T.X. Nguyen, J. Patra, J.K. Chang, and J.M. Ting, High entropy spinel oxide nanoparticles for superior lithiation–delithiation performance, J. Mater. Chem. A, 8(2020), No. 36, p. 18963.

K.H. Tian, C.Q. Duan, Q. Ma, et al., High-entropy chemistry stabilizing spinel oxide (CoNiZnXMnLi)3O4 (X = Fe, Cr) for high-performance anode of Li-ion batteries, Rare Met., 41(2022), No. 4, p. 1265.

H.F. Shang and D.G. Xia, Spinel LiMn2O4 integrated with coating and doping by Sn self-segregation, Int. J. Miner. Metall. Mater., 29(2022), No. 5, p. 909.

F. Yuan, Z. Zhao, Y.L. Zhang, and T. Wu, Effect of Al2O3 content on the viscosity and structure of CaO-SiO2-Cr2O3-Al2O3 slags, Int. J. Miner. Metall. Mater., 29(2022), No. 8, p. 1522.

W.S. Dong, X.K. Wang, and S.Y. Peng, Preparation properties and use in catalysis of spinels, J. Petrochem. Univ. Sinopec, 9(1996), No. 4, p. 10.

Z.Y. Tang, J.J. Feng, and G.X. Xu, Study on multiple doping of spinel LiMn2O4, Acta Chim. Sin., 61(2003), No. 8, p. 1316.

Q. Zhao, C.J. Liu, B. Zhang, M.F. Jiang, J. Qi, H. Saxén, and R. Zevenhoven, Study on extraction of iron from chromite, Steel Res. Int., 86(2015), No. 12, p. 1541.

Y.Z. Huo, H.Z. Gu, A. Huang, et al., Characterization and mechanism of dissolution behavior of Al2O3/MgO oxides in molten slags, J. Iron Steel Res. Int., 29(2022), No. 11, p. 1711.

Q. Zhao, C.J. Liu, T.C. Gao, L. Gao, H. Saxén, and R. Zevenhoven, Remediation of stainless steel slag with MnO for CO2 mineralization, Process. Saf. Environ. Prot., 127(2019), p. 1.

J.L. Li, A.J. Xu, D.F. He, Q.X. Yang, and N.Y. Tian, Effect of FeO on the formation of spinel phases and chromium distribution in the CaO-SiO2-MgO-Al2O3-Cr2O3 system, Int. J. Miner. Metall. Mater., 20(2013), No. 3, p. 253.

Acknowledgements

The authors gratefully acknowledge supports by the National Natural Science Foundation of China (Nos. 52074078 and 52374327), the Applied Fundamental Research Program of Liaoning Province (No. 2023JH2/101600002), the Shenyang Young Middle-Aged Scientific and Technological Innovation Talent Support Program (No. RC220491), the Liaoning Province Steel Industry-University-Research Innovation Alliance Cooperation Project of Bensteel Group (No. KJBLM202202), and the Fundamental Research Funds for the Central Universities (Nos. N2201023 and N2325009).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

All authors declare no competing financial interest.

Rights and permissions

About this article

Cite this article

Yan, Z., Zhao, Q., Han, C. et al. Effects of iron oxide on crystallization behavior and spatial distribution of spinel in stainless steel slag. Int J Miner Metall Mater 31, 292–300 (2024). https://doi.org/10.1007/s12613-023-2713-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-023-2713-7