Abstract

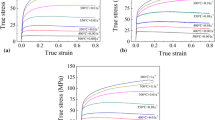

The high temperature compression test of Be/2024Al composites with 62wt% Be was conducted at 500–575°C and strain rate of 0.003–0.1 s−1. The strain-compensated Arrhenius model and modified Johnson–Cook model were introduced to predict the hot deformation behavior of Be/2024Al composites. The result shows that the activation energy of Be/2024Al composites was 363.364 kJ·mol−1. Compared with composites reinforced with traditional ceramics, Be/2024Al composites can be deformed with ultra-high content of reinforcement, attributing to the deformable property of Be particles. The average relative error of the two models shows that modified Johnson–Cook model was more suitable for low temperature condition while strain-compensated Arrhenius model was more suitable for high temperature condition. The processing map was generated and a hot extrusion experiment was conducted according to the map. A comparation of the microstructure of Be/2024Al composites before and after extrusion shows that the Be particle deformed coordinately with the matrix and elongated at the extrusion direction.

Similar content being viewed by others

References

J. Larose and J.J. Lewandowski, Pressure effects on flow and fracture of Be-Al alloys, Metall. Mater. Trans. A, 33(2002), No. 11, p. 3555.

J.Y. Li, Y. Xie, Y.Q. Yang, Z.G. Liu, D.X. Wang, and Y.J. Yin, Research progress of low density and high stiffness of Be-Al alloy fabricated by investment casting, Metals, 12(2022), No. 8, p. 1379.

W. Speer and O.S. Es-Said, Applications of an aluminum-beryllium composite for structural aerospace components, Eng. Fail. Anal., 11(2004), No. 6, p. 895.

C.R. Sandin, L.N. Allen, E.G. Amatucci, et al., Materials evaluation for the origins space telescope, J. Astron. Telesc, Instrum. Syst., 7(2021), No. 1, art. No. 011011.

F.C. Grensing and H. Don, Mechanical and thermal properties of aluminum-beryllium AM162, Adv. Powder. Metall. Part. Mater., (1995), p. 13.

C. Houska, Beryllium in aluminium and magnesium alloys, Met. Mater., 4(1988), No. 2, p. 100.

L.B. Yu, W.Y. Wang, B. Su, et al., Characterizations on the microstructure and micro-mechanics of cast Be-Al-0.4Sc-0.4Zr alloy prepared by vacuum induction melting, Mater. Sci. Eng. A, 744(2019), p. 512.

L.B. Yu, J. Wang, F.S. Qu, et al., Effects of scandium addition on microstructure, mechanical and thermal properties of cast Be-Al alloy, J. Alloys Compd., 737(2018), p. 655.

F. Contreras, E.A. Trillo, and L.E. Murr, Friction-stir welding of a beryllium-aluminum powder metallurgy alloy, J. Mater. Sci., 37(2002), No. 1, p. 89.

S.G. Song, T.J. Garosshen, and V.C. Nardone, Temperature induced worksoftening of Be/Al composite materials, Mater. Sci. Eng. A, 282(2000), No. 1–2, p. 67.

G. Schuster and C. Pokross, High-performance Be-Al casting alloys, [in] B.A. Sadler, ed., Light Metals 2013, Springer, Cham, 2016.

X.D. Liu, P.C. Zhang, S.X. He, Q.D. Xu, Z.Y. Dou, and H.J. Wang, Effect of beryllium content and heat treatment on microstructure and yield strength in Be/6061Al composites, J. Alloys Compd., 743(2018), p. 746.

V.C. Nardone and T.J. Garosshen, Evaluation of the tensile and fatigue behaviour of ingot metallurgy beryllium/aluminium alloys, J. Mater. Sci., 32(1997), No. 15, p. 3975.

Z.Y. Kuang, W.S. Yang, B.Y. Ju, et al., Achieving ultra-high strength in Be/Al composites by self-exhaust pressure infiltration and hot extrusion process, Mater. Sci. Eng. A, 862(2023), art. No. 144473.

G.F. Liu, S.Z. Zhang, L.Q. Chen, and J.X. Qiu, Deformation behavior and microstructural evolution during hot compression of an α + β Ti-6.5Al-3.5Mo-l.5Zr-0.3Si alloy, Int. J. Miner. Metall. Mater., 18(2011), No. 3, p. 344.

A.K. Gupta, V.K. Anirudh, and S.K. Singh, Constitutive models to predict flow stress in austenitic stainless steel 316 at elevated temperatures, Mater. Des., 43(2013), p. 410.

Y.C. Lin, X.M. Chen, and G. Liu, A modified Johnson-Cook model for tensile behaviors of typical high-strength alloy steel, Mater. Sci. Eng. A, 527(2010), No. 26, p. 6980.

Y.H. Xiao and C. Guo, Constitutive modelling for high temperature behavior of 1Cr12Ni3Mo2VNbN martensitic steel, Mater. Sci. Eng. A, 528(2011), No. 15, p. 5081.

Y. Liu, M. Li, X.W. Ren, Z.B. Xiao, X.Y. Zhang, and Y.C. Huang, Flow stress prediction of Hastelloy C-276 alloy using modified Zerilli-Armstrong, Johnson-Cook, and Arrhenius-type constitutive models, Trans. Nonferrous Met. Soc. China, 30(2020), No. 11, p. 3031.

X. Tan, K. Liu, Z.X. Wang, X.B. Yan, W.S. Yang, and G.H. Wu, Mechanical behavior of deformable particles reinforced Al matrix composites, Mater. Sci. Eng. A, 806(2021), art. No. 140815.

P.Z. Shao, G.Q. Chen, B.Y. Ju, et al., Effect of hot extrusion temperature on graphene nanoplatelets reinforced Al6061 composite fabricated by pressure infiltration method, Carbon, 162(2020), p. 455.

M.S. Khorrami, M. Kazeminezhad, Y. Miyashita, and A.H. Kokabi, Improvement in the mechanical properties of Al/SiC nanocomposites fabricated by severe plastic deformation and friction stir processing, Int. J. Miner. Metall. Mater., 24(2017), No. 3, p. 297.

D.Y. Tian, R. Wang, and J. Zheng, Research on the mechanical properties and hot deformation behaviors of spray-deposited 7034 Al alloy processed by forward extrusion, J. Mater. Eng. Perform., 31(2022), No. 1, p. 37.

X.Z. Kai, Y.T. Zhao, A.D. Wang, C.M. Wang, and Z.M. Mao, Hot deformation behavior of in situ nano ZrB2 reinforced 2024Al matrix composite, Compos. Sci. Technol., 116(2015), p. 1.

Z. Fang, Y.T. Zhao, X.Z. Kai, et al., Hot deformation behavior of the AA6016 matrix composite reinforced with in situ ZrB2 and Al2O3 nanoparticles, Mater. Res. Express, 7(2020), No. 2, art. No. 026508.

C. Zener and J.H. Hollomon, Effect of strain rate upon plastic flow of steel, J. Appl. Phys., 15(1944), No. 1, p. 22.

Y. Wang, D.L. Lin, and C.C. Law, A correlation between tensile flow stress and Zener-Hollomon factor in TiAl alloys at high temperatures, J. Mater. Sci. Lett., 19(2000), No. 13, p. 1185.

J.J. Jonas, C.M. Sellars, and W.J.M. Tegart, Strength and structure under hot-working conditions, Metall. Rev., 14(1969), No. 1, p. 1.

L. Zhou, Z.Y. Huang, C.Z. Wang, X.X. Zhang, B.L. Xiao, and Z.Y. Ma, Constitutive flow behaviour and finite element simulation of hot rolling of SiCp/2009Al composite, Mech. Mater., 93(2016), p. 32.

S.M. Hao, J.P. Xie, A.Q. Wang, W.Y. Wang, and J.W. Li, Hot deformation behavior and processing map of SiCp/2024Al composite, Rare Met. Mater. Eng., 43(2014), No. 12, p. 2912.

K.K. Wang, X.P. Li, Q.L. Li, G.G. Shu, and G.Y. Tang, Hot deformation behavior and microstructural evolution of particulate-reinforced AA6061/B4C composite during compression at elevated temperature, Mater. Sci. Eng. A, 696(2017), p. 248.

S.P. Liu, D.F. Li, and S.L. Guo, Critical conditions of dynamic recrystallization for B4Cp/6061Al composite, Rare Met. Mater. Eng., 46(2017), No. 7, p. 1815.

B.Q. Han, K.C. Chan, T.M. Yue, and W.S. Lau, High temperature deformation behavior of Al2124-SiCp composite, J. Mater. Process. Technol., 63(1997), No. 1–3, p. 395.

X.P. Li, C.Y. Liu, K. Luo, M.Z. Ma, and R.P. Liu, Hot deformation behaviour of SiC/AA6061 composites prepared by spark plasma sintering, J. Mater. Sci. Technol., 32(2016), No. 4, p. 291.

Z. Wang, A.Q. Wang, J.P. Xie, and P. Liu, Hot deformation behavior and strain-compensated constitutive equation of nano-sized SiC particle-reinforced Al-Si matrix composites, Materials, 13(2020), No. 8, art. No. 1812.

S.M. Hao, J.P. Xie, A.Q. Wang, W.Y. Wang, and J.W. Li, Hot deformation behavior and power dissipation map of middle volume fraction SiCp/Al composite, Trans. Mater. Heat Treat., 35(2014), No. 3, p. 30.

K.C. Nayak and P. Date, Development of constitutive relationship for thermomechanical processing of Al-SiC composite eliminating deformation heating, J. Mater. Eng. Perform., 28(2019), p. 5323.

A. Rudra, M. Ashiq, S. Das, and R. Dasgupta, Constitutive modeling for predicting high-temperature flow behavior in aluminum 5083 + 10wt pct SiCp composite, Metall. Mater. Trans. B, 50(2019), No. 2, p. 1060.

H.T. Chi, Thermal Deformation Behavior and Friction and Wear Property of TiB2p/2024Al Composite [Dissertation], Harbin Institute of Technology, Harbin, 2013, p. 31.

C.X. Lu, L.M. Wang, W. He, et al., Research progress in preparation process and elasticity modulus of SiC particle reinforced aluminum based composites, Electr. Eng. Mater., 2022, No. 4, p. 6.

N.N. Song, Z. Gao, Y.Y. Zhang, and X.D. Li, B4C nanoskeleton enabled, flexible lithium-sulfur batteries, Nano Energy, 58(2019), p. 30.

J.J. Li, Z.Y. Fu, J.Y. Zhang, et al., Microstructure and mechanical properties of gas pressure sinterning TiB2-Al2O3 multiphase ceramics, J. Chin. Ceram. Soc., 2007, No. 8, p. 973.

F.X. Cao, K.K. Deng, C.J. Wang, K.B. Nie, W. Liang, and J.F. Fan, Synergistic enhancement of the strength-ductility for stir casting SiCp/2024Al composites by two-step deformation, Met. Mater. Int., 27(2021), No. 12, p. 5450.

J.J. Lewandowski and J. Larose, Effects of processing conditions and test temperature on fatigue crack growth and fracture toughness of Be-Al metal matrix composites, Mater. Sci. Eng. A, 344(2003), No. 1–2, p. 215.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Nos. 52171136, 51871072, and 51871073), the Excellent Youth Scholars project of Natural Science Foundation of Heilongjiang Province (No. YQ2021E 016), and Heilongjiang Touyan Team Program.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

About this article

Cite this article

Xia, Y., Kuang, Z., Zhu, P. et al. Hot deformation behavior and microstructure evolution of Be/2024Al composites. Int J Miner Metall Mater 30, 2245–2258 (2023). https://doi.org/10.1007/s12613-023-2662-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-023-2662-1