Abstract

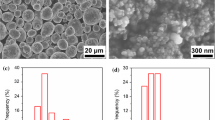

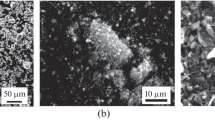

Copper matrix composites reinforced by in situ-formed hybrid titanium boride whiskers (TiBw) and titanium diboride particles (TiB2p) were fabricated by powder metallurgy. Microstructural observations showed competitive precipitation behavior between TiBw and TiB2p, where the relative contents of the two reinforcements varied with sintering temperature. Based on thermodynamic and kinetic assessments, the precipitation mechanisms of the hybrid reinforcements were discussed, and the formation of both TiBw and TiB2p from the local melting zone was thermodynamically favored. The precipitation kinetics were mainly controlled by a solid-state diffusion of B atoms. By forming a compact compound layer, in situ reactions were divided into two stages, where Zener growth and Dybkov growth prevailed, respectively. Accordingly, the competitive precipitation behavior was attributed to the transition of the growth model during the reaction process.

Similar content being viewed by others

References

I.A. Ibrahim, F.A. Mohamed, and E.J. Lavernia, Particulate reinforced metal matrix composites—A review, J. Mater. Sci., 26(1991), No. 5, p. 1137.

P. Sharma, D. Khanduja, and S. Sharma Production of hybrid composite by a novel process and its physical comparison with single reinforced composites, Mater. Today Proc., 2(2015), No. 4–5, p. 2698.

B.N. Sarada, P.L.S. Murthy, and G. Ugrasen, Hardness and wear characteristics of hybrid aluminium metal matrix composites produced by stir casting technique, Mater. Today Proc., 2(2015), No. 4–5, p. 2878.

J.H. Gu, X.N. Zhang, and M.Y. Gu, Mechanical properties and damping capacity of (SiCp+Al2O3-SiO2f)/Mg hybrid metal matrix composite, J. Alloys Compd., 385(2004), No. 1–2, p. 104.

S.Y. Sun, M.M. Wang, L.Q. Wang, J.N. Qin, W.J. Lu, and D. Zhang, The influences of trace TiB and TiC on microstructure refinement and mechanical properties of in situ synthesized Ti matrix composite, Composites Part B, 43(2012), No. 8, p. 3334.

X.L. Guo, W.J. Lu, L.Q. Wang, and J.N. Qin, A research on the creep properties of titanium matrix composites rolled with different deformation degrees, Mater. Des., 63(2014), p. 50.

M.J. Shen, X.J. Wang, C.D. Li, M.F. Zhang, X.S. Hu, M.Y. Zheng, and K. Wu, Effect of bimodal size SiC particulates on microstructure and mechanical properties of AZ31B magnesium matrix composites, Mater. Des., 52(2013), No. 7, p. 1011.

L.J. Huang, L. Geng, and H.X. Peng, Microstructurally inhomogeneous composites: Is a homogeneous reinforcement distribution optimal, Prog. Mater. Sci., 71(2015), p. 93.

Z. Li, Q. Guo, Z.Q. Li, G.L. F, D.B. Xiong, Y.S. Su, J. Zhang, and D. Zhang, Enhanced mechanical properties of graphene (reduced graphene oxide)/aluminum composites with a bioin-spired nanolaminated structure, Nano Lett., 15(2015), No. 12, p. 8077.

M.O. Bodunrin, K.K. Alaneme, and L.H. Chown, Aluminium matrix hybrid composites: A review of reinforcement philosophies; mechanical, corrosion and tribological characteristics, J. Mater. Res. Technol., 4(2015), No. 4, p. 434.

J. Singh and A. Chauhan, Characterization of hybrid aluminum matrix composites for advanced applications—A review, J. Mater. Res. Technol., 5(2016), No. 2, p. 159.

L. Geng, D.R. Ni, J. Zhang, and Z.Z. Zheng, Hybrid effect of TiBw and TiCp on tensile properties of in situ titanium matrix composites, J. Alloys Compd., 463(2008), No. 1–2, p. 488.

S.H. Liang, W.Z. Li, Y.H. Jiang, F. Cao, G.Z. Dong, and P. Xiao, Microstructures and properties of hybrid copper matrix composites reinforced by TiB whiskers and TiB2 particles, J. Alloy. Compd., 797(2019), p. 589.

Y.H. Jiang, D. Li, S.H. Liang, and F. Liu, Phase selection of titanium boride in copper matrix composites during solidification, J. Mater. Sci., 52(2017), p. 2957.

Y.H. Jiang, C. Wang, S.H. Liang, J.Q. Ren, X. Du, and F. Liu, TiB2(-TiB)/Cu in-situ composites prepared by hot-press with the sintering temperature just beneath the melting point of copper, Mater. Charact., 121(2016), p. 76.

Y.H. Liang, H.Y. Wang, Y.F. Yang, Y.L. Du, and Q.C. Jiang, Reaction path of the synthesis of TiC-TiB2 in Cu-Ti-B4C system, Int. J. Refract. Met. Hard Mater., 26(2008), No. 4, p. 383.

I. Ansara, A.T. Dinsdale, and M.H. Rand, Al-Mg COST507: Thermochemical Database for Light Metal Alloys, European Commission, Belgium, 1998.

D. Holland-Moritz, Short-range order and solid-liquid interfaces in undercooled metallic melts, Mater. Sci. Eng. A, 304–306(2001), p. 108.

M.W. Chase, NIST-JANAF thermochemical tables for oxygen fluorides, J. Phys. Chem. Ref. Data, 25(1996), No. 2, p. 551.

D. Turnbull, Formation of crystal nuclei in liquid metals, J. Appl. Phys., 21(1950), No. 10, p. 1022.

C.V. Thompson and F. Spaepen, Homogeneous crystal nucleation in binary metallic melts, Acta Metall., 31(1983), No. 12, p. 2021.

M. Füllgrabe, B. Ittermann, H.J. Stöckmann, F. Kroll, D. Peters, and H. Ackermann, Diffusion parameters of B in Cu determined by β-radiation-detected NMR, Phys. Rev. B, 64(2001), No. 22, art. No. 224302.

V.I. Dybkov, Reaction diffusion in heterogeneous binary systems, J. Mater. Sci., 21(1986), No. 9, p. 3078.

Z. Fan, Z.X. Guo, and B. Cantor, The kinetics and mechanism of interfacial reaction in sigma fibre-reinforced Ti MMCs, Composites Part A, 28(1997), No. 2, p. 131.

Y. Iijima, K. Hoshino, and K.I. Hirano, Diffusion of titanium in copper, Metall. Trans. A, 8(1977), No. 6, p. 997.

C. Zener, Theory of growth of spherical precipitates from solid solution, J. Appl. Phys., 20(1949), No. 10, p. 950.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Nos. U1502274, 51834009, and 51974244).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Lan, T., Jiang, Yh., Zhang, Xj. et al. Competitive precipitation behavior of hybrid reinforcements in copper matrix composites fabricated by powder metallurgy. Int J Miner Metall Mater 28, 1090–1096 (2021). https://doi.org/10.1007/s12613-020-2052-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-020-2052-x