Abstract

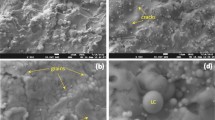

La2Zr2O7 thermal barrier coatings (TBCs) with dispersed Pt particles were prepared by cathode plasma electrolytic deposition (CPED) with ceramic balls added to the cathode region. Compared with the conventional CPED, when ceramic balls are used in the cathode region, the plasma discharge ignition current density decreases approximately 62-fold and the stable plasma discharges occur at the whole cathode surface. Such TBCs with a thickness of 100 μm exhibit a crack-free surface and are composed of pyrochlore-structured La2Zr2O7. Cyclic oxidation, scratching, and thermal insulation capability tests show that such TBCs not only exhibit high resistance to oxidation and spallation but also provide good thermal insulation. These beneficial effects are attributed to the excellent properties of TBCs, such as good thermal insulation because of low thermal conductivity, high-temperature oxidation resistance because of low-oxygen diffusion rate, and good mechanical properties because of the toughening effect of Pt particles.

Similar content being viewed by others

References

R. Vaβen, M.O. Jarligo, T. Steinke, D.E. Mack, and D. Stöver, Overview on advanced thermal barrier coatings, Surf. Coat. Technol., 205(2010), No. 4, p. 938.

R. Vaβen, H. Kaβner, A. Stuke, F. Hauler, D. Hathiramani, and D. Stöver, Advanced thermal spray technologies for applications in energy systems, Surf. Coat. Technol., 202(2008), No. 18, p. 4432.

G.W. Goward, Progress in coatings for gas turbine airfoils, Surf. Coat. Technol., 108-109(1998), p. 73.

X.Q. Cao, R. Vassen, and D. Stoever, Ceramic materials for thermal barrier coatings, J. Eur. Ceram. Soc., 24(2004), No. 1, p. 1.

N.P. Padture, M. Gell, and E.H. Jordan, Thermal barrier coatings for gasturbine engine applications, Science, 296(2002), No. 5566, p. 280.

R.A. Miller, Thermal barrier coatings for aircraft engines: history and directions, J. Therm. Spray Technol., 6(1997), p. 35.

M. Gupta, N. Curry, P. Nylén, N. Markocsan, and R. Vaβen, Design of next generation thermal barrier coatings: experiments and modeling, Surf. Coat. Technol., 220(2013), p. 20.

T.R. Kakuda, A.M. Limarga, T.D. Bennett, and D.R. Clarke, Evolution of thermal properties of EBPVD 7YSZ thermal barrier coatings with thermal cycling, Acta Mater., 57(2009), No. 8, p. 2583.

R. Vaβen and D. Stöver, Functional Gradient Materials and Surface Layers Prepared by Fine Particles Technology, Springer, Kiev, 2001, p. 199.

A.G. Evans, D.R. Mumm, J.W. Hutchinson, G.H. Meier, and F.S. Pettit, Mechanisms controlling the durability of thermal barrier coatings, Prog. Mater. Sci., 46(2001), No. 5, p. 505.

A.K. Rai, M.P. Schmitt, R.S. Bhattacharya, D.M. Zhu, and D.E. Wolfe, Thermal conductivity and stability of multilayered thermal barrier coatings under high temperature annealing conditions, J. Eur. Ceram. Soc., 35(2015), No. 5, p. 1605.

X.Q. Cao, R. Vassen, W. Jungen, S. Schwartz, F. Tietz, and D. Stöver, Thermal stability of lanthanum zirconate plasmasprayed coating, J. Am. Ceram. Soc., 84(2001), No. 9, p. 2086.

T. Strangman, D. Raybould, A. Jameel, and W. Baker, Damage mechanisms, life prediction, and development of EBPVD thermal barrier coatings for turbine airfoils, Surf. Coat. Technol., 202(2007), No. 4, p. 658.

V.K. Tolpygo, D.R. Clarke, and K.S. Murphy, Evaluation of interface degradation during cyclic oxidation of EBPVD thermal barrier coatings and correlation with TGO luminescence, Surf. Coat. Technol., 188-189(2004), p. 62.

A. Rabiei and A.G. Evans, Failure mechanisms associated with the thermally grown oxide in plasmasprayed thermal barrier coatings, Acta Mater., 48(2000), No. 15, p. 3963.

R. Vaβen, X. Cao, F. Tietz, D. Basu, and D. Stöver, Zirconates as new materials for thermal barrier coatings, J. Am. Ceram. Soc., 83(2000), p. 2023.

C.G. Levi, Emerging materials and processes for thermal barrier systems, Curr. Opin. Solid State Mater. Sci., 8(2004), No. 1, p. 77.

J.Q. Yao, Y.D. He, D.R. Wang, H. Peng, H.B. Guo, and S.K. Gong, Thermal barrier coating bonded by (Al2O3–Y2O3)/(Y2O3-stabilized ZrO2) laminated composite coating prepared by twostep cyclic spray pyrolysis, Corros. Sci., 80(2014), p. 37.

R. Bermejo, J. Pascual, T. Lube, and R. Danzer, Optimal strength and toughness of Al2O3–ZrO2 laminates designed with external or internal compressive layers, J. Eur. Ceram. Soc., 28(2008), No. 8, p. 1575.

S.M.A. Shibli, F. Chacko, and C. Divya, Al2O3–ZrO2 mixed oxide composite incorporated aluminium rich zinc coatings for high wear resistance, Corros. Sci., 52(2010), No. 2, p. 518.

C. Ren, Y.D. He, and D.R. Wang, Hightemperature cyclic oxidation behavior of Al2O3–YAG composite coating prepared by EPD and microwave sintering, Appl. Surf. Sci., 258(2012), No. 15, p. 5739.

X.X. Ma, Y.D. He, D.R. Wang, and J. Zhang, Enhanced hightemperature corrosion resistance of (Al2O3–Y2O3)/Pt microlaminated coatings on 316L stainless steel alloy, Corros. Sci., 54(2012), p. 183.

J. Yao, Y. He, D. Wang, and J. Lin, High-temperature oxidation resistance of (Al2O3–Y2O3)/(Y2O3-stabilized ZrO2) laminated coating on 8Nb–TiAl alloy prepared by a novel spray pyrolysis, Corros. Sci., 80(2014), p. 19.

K. Zhang, G. Wang, Z. Wang, C. Wang, and W. Han, Fabrication and superplasticity of Al2O3/3Y-TZP laminated composite, J. Eur. Ceram. Soc., 26(2006), No. 3, p. 253.

S. Nath, I. Manna, and J.D. Majumdar, Kinetics and mechanism of isothermal oxidation of compositionally graded yttria stabilized zirconia (YSZ) based thermal barrier coating, Corros. Sci., 88(2014), p. 10.

L. Wang, Y. Wang, X.G. Sun, J.Q. He, Z.Y. Pan, and C.H. Wang, Thermal shock behavior of 8YSZ and double-ceramic-layer La2Zr2O7/8YSZ thermal barrier coatings fabricated by atmospheric plasma spraying, Ceram. Int., 38(2012), No. 5, p. 3595.

J.Y. Li, H. Dai, X.H. Zhong, Y.F. Zhang, X.F. Ma, J. Meng, and X.Q. Cao, Lanthanum zirconate ceramic toughened by BaTiO3 secondary phase, J. Alloys Compd., 452(2008), No. 2, p. 406.

X. Ma, Y. He, and D. Wang, Preparation and high-temperature properties of Au nano-particles doped α-Al2O3 composite coating on TiAl-based alloy, Appl. Surf. Sci., 257(2011), No. 3, p. 10273.

J. Yao, Y. He, D. Wang, H. Peng, H. Guo, and S. Gong, Thermal barrier coatings with (Al2O3–Y2O3)/(Pt or Pt–Au) composite bond coat and 8YSZ top coat on Ni-based superalloy, Appl. Surf. Sci., 286(2013), p. 298.

A.L. Yerokhin, X. Nie, A. Leyland, A. Matthews, and S.J. Dowey, Plasma electrolysis for surface engineering, Surf. Coat. Technol., 122(1999), No. 2-3, p. 73.

E.I. Meletis, X. Nie, F.L. Wang, and J.C. Jiang, Electrolytic plasma processing for cleaning and metal-coating of steel surfaces, Surf. Coat. Technol., 150(2002), No. 2-3, p. 246.

T. Paulmier, J.M. Bell, P.M. Fredericks, Development of a novel cathodic plasma/electrolytic deposition technique: Part 2. Physico-chemical analysis of the plasma discharge, Surf. Coat. Technol., 201(2007), No. 21, p. 8771.

P. Gupta, G. Tenhundfeld, E.O. Daigle, and D. Ryabkov, Electrolytic plasma technology: science and engineering — an overview, Surf. Coat. Technol., 201(2007), No. 21, p. 8746.

E.V. Parfenov, A. Yerokhin, R.R. Nevyantseva, M.V. Gorbatkov, C.J. Liang, and A. Matthews, Towards smart electrolytic plasma technologies: an overview of methodological approaches to process modelling, Surf. Coat. Technol., 269(2015), p. 2.

Y.D. He, P. Wang, S.J. Deng, W.Z. Wang, S. Zhou, J. Zhang, and D.R. Wang, Thermal Barrier Coatings with Dispersed Noble Metal Particles Prepared by Cathode Plasma Electrolytic Deposition, Chinese Patent, Appl.201410265417.0, 2014.

F. Yang, X.F. Zhao, and P. Xiao, Thermal conductivities of YSZ/Al2O3 composites, J. Eur. Ceram. Soc., 30(2010), No. 15, p. 3111.

H. Vogt and H.D. Kleinschrodt, Ohmic interelectrode voltage drop in alumina reduction cells, J. Appl. Electrochem., 33(2003), No. 7, p. 563.

A.A. Dahlkild, Modelling the two-phase flow and current distribution along a vertical gas-evolving electrode, J. Fluid Mech., 428(2001), p. 249.

J.M. Meek, A theory of spark discharge, Phys. Rev., 57(1940), p. 722.

L. Minervini, R.W. Grimes, and K.E. Sickafus, Disorder in pyrochlore oxides, J. Am. Ceram. Soc., 83(2000), No. 8, p. 1873.

H.E. Evans, Cracking and spalling of protective oxide layers, Mater. Sci. Eng. A, 120-121(1989), p. 139.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Deng, Sj., Wang, P., He, Yd. et al. La2Zr2O7 TBCs toughened by Pt particles prepared by cathode plasma electrolytic deposition. Int J Miner Metall Mater 23, 704–715 (2016). https://doi.org/10.1007/s12613-016-1284-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-016-1284-2