Abstract

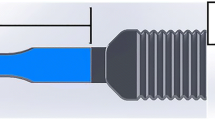

In this study, a serpentine channel pouring process was used to prepare the semi-solid Al–20%Si alloy slurry and refine primary Si grains in the alloy. The effects of the pouring temperature, number of curves in the serpentine channel, and material of the serpentine channel on the size of primary Si grains in the semi-solid Al–20%Si alloy slurry were investigated. The results showed that the pouring temperature, number of the curves, and material of the channel strongly affected the size and distribution of the primary Si grains. The pouring temperature exerted the strongest effect, followed by the number of the curves and then the material of the channel. Under experimental conditions of a four-curve copper channel and a pouring temperature of 701°C, primary Si grains in the semi-solid Al–20%Si alloy slurry were refined to the greatest extent, and the lath-like grains were changed into granular grains. Moreover, the equivalent grain diameter and the average shape coefficient of primary Si grains in the satisfactory semi-solid Al–20%Si alloy slurry were 24.4 μm and 0.89, respectively. Finally, the refinement mechanism and distribution rule of primary Si grains in the slurry prepared through the serpentine channel pouring process were analyzed and discussed.

Similar content being viewed by others

References

H. Yamagata, H. Kurita, M. Aniolek, W. Kasprzak, and J.H. Sokolowski, Thermal and metallographic characteristics of the Al?20% Si high-pressure die-casting alloy for monolithic cylinder blocks, J. Mater. Process. Technol., 199(2008), No. 1-3, p. 84.

L.G. Hou, Y.H. Cai, H. Cui, and J.S. Zhang, Microstructure evolution and phase transformation of traditional cast and spray-formed hypereutectic aluminium?silicon alloys induced by heat treatment, Int. J. Miner. Metall. Mater., 17(2010), No. 3, p. 297.

H.C. Liao, Y. Sun, and G.X. Sun, Effect of Al?5Ti?1B on the microstructure of near-eutectic Al?13.0%Si alloys modified with Sr, J. Mater. Sci., 37(2002), No. 16, p. 3489.

W.S. Liu, R.C. Wang, C.Q. Peng, J.Y. Mo, X.W. Zhu, and J. Peng, Research progress of spray deposited high Si?Al alloys for electronic packaging, Trans. Nonferrous Met. Soc. China, 22(2012), No. 12, p. 3446.

L. Lasa and J.M. Rodriguez-Ibabe, Wear behaviour of eutectic and hypereutectic Al?Si?Cu?Mg casting alloys tested against a composite brake pad, Mater. Sci. Eng. A, 363(2003), No. 1-2, p. 193.

T. Hejwowski and A. Weronski, The effect of thermal barrier coatings on diesel engine performance, Vacuum, 65(2002), No. 3-4, p. 427.

M. Sheng, Z.D. Tao, P. Jia, J.F. Leng, and H.R. Geng, Effects of Y and Y combined with Al?5Ti?1B on the microstructure and mechanical properties of hypoeutectic Al?Si alloy, JOM, 67(2015), No. 2, p. 330.

K. Nogita and A.K. Dahle, Effects of boron on eutectic modification of hypoeutectic Al?Si alloys, Scripta Mater., 48(2003), No. 3, p. 307.

L.L. Ge, R.P. Liu, G. Li, M.Z. Ma, and W.K. Wang, Solidification of Al?50 at.%Si alloy in a drop tube, Mater. Sci. Eng. A, 385(2004), No. 1-2, p. 128.

J. Schmitz, B. Hallstedt, J, Brillo, I. Egry, and M, Schick, Density and thermal expansion of liquid Al?Si alloys, J. Mater. Sci., 47(2012), No. 8, p. 3706.

C. Li, C.Q. Peng, K. Yu, R.C. Wang, J. Yang, and R. Liu, Microstructure and properties of spray deposition 70%Si?Al alloy for electronic packaging applications, Trans. Nonferrous Met. Soc. China, 19(2009), No. 2, p. 303.

T. Aruna, M. Rashmi, and S. Devendra, Strength and elongation of spray formed Al?Si?Pb alloys, Int. J. Miner. Metall. Mater., 21(2014), No. 12, p. 1222.

B. Yang, Y. Jiang, X.N. Ding, H.H. Zhong, and X.P. Li, Hot-pressing synthesis and characterization of Al?50%Si alloy electronic packaging mateaials, Powder Metall. Ind., 22(2012), No. 5, p. 24.

S. Nafisi and R. Ghomashchi, The microstructural characterization of semi-solid slurries, JOM, 58(2006), No. 6, p. 24.

M.C. Flemings, Behavior of metal alloys in the semisolid state, Metall. Trans. A, 22(1991), No. 5, p. 957.

M. Asta, C. Beckermann, A. Karma, W. Kurz, R. Napolitano, M. Plapp, G. Purdy, M. Rappaz, and R. Trivedi, Solidification microstructures and solid-state parallels: recent developments, future directions, Acta Mater., 57(2009), No. 4, p. 941.

J.W. Zhao, S.S. Wu, L.Z. Xie, P. An, and Y.W. Mao, Effects of vibration and grain refiner on microstructure of semisolid slurry of hypoeutectic Al?Si alloy, Trans. Nonferrous Met. Soc. China, 18(2008), No. 4, p. 842.

X. Li, Y.D. Li, Y. Ma, T.J. Chen, and Y. Hao, Effect of mixing ways on primary silicon of hypereutectic Al?Si alloys during controlled diffusion solidification, Chin. J. Nonferrous Met., 21(2011), No. 12, p. 3033.

R.D. Doherty and J.A. Szpunar, Kinetics of sub-grain coalescence: a reconsideration of the theory, Acta Metall., 32(1984), No. 10, p. 1789.

A. Mazahery and M.O. Shabani, Modification mechanism and microstructural characteristics of eutectic Si in casting Al?Si alloys: a review on experimental and numerical studies, JOM, 66(2014), No. 5, p. 726.

J.V. Goñi, J.M. Rodriguez-Ibabe, and J.J. Urcola, Strength and toughness of semi-solid processed hypereutectic Al/Si alloys, Scripta Mater., 34(1996), No. 3, p. 483.

J.F. Jiang, X. Lin, Y. Wang, J.J. Qu, and S.J. Luo, Microstructural evolution of AZ61 magnesium alloy predeformed by ECAE during semisolid isothermal treatment, Trans. Nonferrous Met. Soc. China, 22(2012), No. 3, p. 555.

Z. Liu, W.M. Mao, and Z.D. Zhao, Research on semi-solid slurry of a hypoeutectic Al?Si alloy prepared by low superheat pouring and weak electromagnetic stirring, Rare Met., 25(2006), No. 2, p. 177.

Z.Y. Liu, Preparation of Semi-solid Slurry by the Serpentine Channel and Rheo-diecasting Process of A380 Aluminum Alloy [Dissertation], University of Science and Technology Beijing, Beijing, 2015, p. 61.

R.P. Liu, D.M. Herlach, M. Vandyoussefi, and A.L. Greer, Morphologies of silicon crystals solidified on a chill plate, Metall. Mater. Trans. A, 35(2004), No. 3, p. 1067.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zheng, Zk., Mao, Wm., Liu, Zy. et al. Refinement of primary Si grains in Al–20%Si alloy slurry through serpentine channel pouring process. Int J Miner Metall Mater 23, 572–580 (2016). https://doi.org/10.1007/s12613-016-1268-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-016-1268-2