Abstract

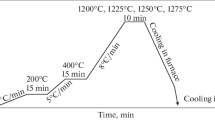

A multilayer tungsten carbide particle (WCp)-reinforced Ni-based alloy coating was fabricated on a steel substrate using vacuum cladding technology. The morphology, microstructure, and formation mechanism of the coating were studied and discussed in different zones. The microstructure morphology and phase composition were investigated by scanning electron microscopy, optical microscopy, X-ray diffraction, and energy-dispersive X-ray spectroscopy. In the results, the coating presents a dense and homogeneous microstructure with few pores and is free from cracks. The whole coating shows a multilayer structure, including composite, transition, fusion, and diffusion-affected layers. Metallurgical bonding was achieved between the coating and substrate because of the formation of the fusion and diffusion-affected layers. The Ni-based alloy is mainly composed of γ-Ni solid solution with finely dispersed Cr7C3/Cr23C6, CrB, and Ni+Ni3Si. WC particles in the composite layer distribute evenly in areas among initial Ni-based alloying particles, forming a special three-dimensional reticular microstructure. The macrohardness of the coating is HRC 55, which is remarkably improved compared to that of the substrate. The microhardness increases gradually from the substrate to the composite zone, whereas the microhardness remains almost unchanged in the transition and composite zones.

Similar content being viewed by others

References

K. Simunovic, T. Saric, and G. Simunovic, Different approaches to the investigation and testing of the Ni-based self-fluxing alloy coatings — a review: Part 1. General facts, wear and corrosion investigations, Tribol. Trans., 57(2014), No. 6, p. 955.

Y.S. Park and D.H. Bae, Assessment of the crack growth characteristics at the low fatigue limit of a multi-pass welded Ni-based alloy 617, J. Mech. Sci. Technol., 28(2014), No. 4, p. 1251.

Y.S. Lim, D.J. Kim, S.S. Hwang, H.P. Kim, and S.W. Kim, M23C6 precipitation behavior and grain boundary serration in Ni-based Alloy 690, Mater. Charact., 96(2014), p. 28.

K. Simunovic, T. Saric, and G. Simunovic, Different approaches to the investigation and testing of the Ni-based self-fluxing alloy coatings — a review: Part 2. Microstructure, adhesive strength, cracking behavior, and residual stresses investigations, Tribol. Trans., 57(2014), No. 6, p. 980.

N.Y. Sari and M. Yilmaz, Improvement of wear resistance of wire drawing rolls with Cr–Ni–B–Si+WC thermal spraying powders, Surf. Coat. Technol., 202(2008), No. 13, p. 3136.

F. Fernandes, A. Ramalho, A. Loureiro, J.M. Guilemany, M. Torrell, and A. Cavaleiro, Influence of nanostructured ZrO2 additions on the wear resistance of Ni-based alloy coatings deposited by APS process, Wear, 303(2013), No. 1-2, p. 591.

T. Liyanage, G. Fisher, and A.P. Gerlich, Influence of alloy chemistry on microstructure and properties in NiCrBSi overlay coatings deposited by plasma transferred arc welding (PTAW), Surf. Coat. Technol., 205(2010), No. 3, p. 759.

S. Yang, N. Chen, W.J. Liu, M.L. Zhong, Z.J. Wang, and H. Kokawa, Fabrication of nickel composite coatings reinforced with TiC particles by laser cladding, Surf. Coat. Technol., 183(2004), No. 2-3, p. 254.

T.S. Sidhu, S. Prakash, and R.D. Agrawal, Characterisations of HVOF sprayed NiCrBSi coatings on Ni-and Fe-based superalloys and evaluation of cyclic oxidation behaviour of some Ni-based superalloys in molten salt environment, Thin Solid Films, 515(2006), No. 1, p. 95.

T.P. Xuan and D. Min, Effect of rare earth on microstructure of vacuum melting Ni-based self-fluxing alloy coatings, J. Rare Earths, 22(2004), No. 4, p. 517.

C. Guo, J.M. Chen, J.S. Zhou, J.R. Zhao, L.Q. Wang, Y.J. Yu and H.D. Zhou, Effects of WC–Ni content on microstructure and wear resistance of laser cladding Ni-based alloys coating, Surf. Coat. Technol., 206(2012), No. 8-9, p. 2064.

C. Sudha, P. Shankar, R.V. Subba Rao, R. Thirumurugesan, M. Vijayalakshmi, and B. Raj, Microchemical and microstructural studies in a PTA weld overlay of Ni–Cr–Si–B alloy on AISI 304L stainless steel, Surf. Coat. Technol., 202(2008), No. 10, p. 2103.

K. Van Acker, D. Vanhoyweghen, R. Persoons, and J. Vangrunderbeek, Influence of tungsten carbide particle size and distribution on the wear resistance of laser clad WC/Ni coatings, Wear, 258(2005), No. 1-4, p. 194.

G. Goller, The effect of bond coat on mechanical properties of plasma sprayed bioglass-titanium coatings, Ceram. Int., 30(2004), No. 3, p. 351.

S. Nowotny, A. Techel, A. Luft, and W. Reitzenstein, Microstructure and wear properties of laser clad carbide coatings, [in] 12th International Congress on Applications of Lasers and Electro-Optics, Orlando, 1993, p. 9.

K.L. Scrivener, Backscattered electron imaging of cementitious microstructures: understanding and quantification, Cem. Concr. Compos., 26(2004), No. 8, p. 935.

Q. Li, D.W. Zhang, T.Q. Lei, C.Z. Chen, and W.Z. Chen, Comparison of laser-clad and furnace-melted Ni-based alloy microstructures, Surf. Coat. Technol., 137(2001), No. 2-3, p. 122.

P.X. Wang, Powder Metallurgy, Metallurgy Industry Press, Beijing, 1997, p. 268.

Z.Q. Cui and Y.C. Qin, Metallography and Heat Treatment, China Machine Press, Beijing, 2007, p. 311.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, Gr., Huang, Cp., Song, Wm. et al. Microstructure characteristics of Ni/WC composite cladding coatings. Int J Miner Metall Mater 23, 184–192 (2016). https://doi.org/10.1007/s12613-016-1226-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-016-1226-z