Abstract

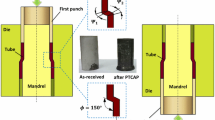

A new horizontal continuous casting method with heating-cooling combined mold (HCCM) technology was explored for fabricating high-quality thin-wall cupronickel alloy tubes used for heat exchange pipes. The microstructure and mechanical properties of BFe10 cupronickel alloy tubes fabricated by HCCM and traditional continuous casting (cooling mold casting) were comparatively investigated. The results show that the tube fabricated by HCCM has smooth internal and external surfaces without any defects, and its internal and external surface roughnesses are 0.64 μm and 0.85 μm, respectively. The tube could be used for subsequent cold processing without other treatments such as surface planning, milling and acid-washing. This indicates that HCCM can effectively reduce the process flow and improve the production efficiency of a BFe10 cupronickel alloy tube. The tube has columnar grains along its axial direction with a major casting texture of \(\left\{ {012} \right\}\left\langle {6\bar 21} \right\rangle\). Compared with cooling mold casting (δ = 36.5%), HCCM can improve elongation (δ = 46.3%) by 10% with a slight loss of strength, which indicates that HCCM remarkably improves the cold extension performance of a BFe10 cupronickel alloy tube.

Similar content being viewed by others

References

T.J. Glover, Copper-nickel alloy for the construction of ship and boat hulls, Br. Corros. J., 17(1982), No.4, p.155.

H.L. Li, H.F. Lou, and K.D. Ma, Question and Answer for Copper Production Technology, Metallurgical Industry Press, Beijing, 2008, p.89.

Z.M. Yan, X.T. Li, K. Qi, Z.Q. Cao, X.L. Zhang, and T.J. Li Study on horizontal electromagnetic continuous casting of CuNi10Fe1Mn alloy hollow billets, Mater. Des., 30(2009), No.6, p.2072.

A. Ohno, G. Motoyasu, and H. Kawai, Strengthening and bending deformability of Al-4.5 mass% Mg alloy billets produced by heated mold continuous casting method (OCC), Light Met., 40(1990), No.11, p.817.

Y.Q. Yu, F. Zhao, and W.G. Li, Microstructure and performance of BFe30-1-1 cupronickel tubes, Hot work. Technol., 2005, No.11, p.8.

C.L. Gan, X.F. Liu, H.Y. Huang, and J.X. Xie, Fabrication process, microstructure and mechanical properties of BFe10-1-1 alloy tubes by continuous unidirectional solidification, Acta Metall. Sin., 46(2010), No.12, p.1549.

J.X. Xie, H.F. Lou, Z.D. Wang, P.X. Hu, H. Zhang, Y.Z. Dong, J.L. Kang, G..W. Miao, X.Z. Fu, M. Yan, B.H. Guan, and X.L. Jiang, Compact Process for Fabrication of Copper and Copper Alloy Precision Tube, Chinese Patent, Appl. ZL200710065281.9, 2009.

J.X. Xie, J. Mei, X.H. Liu, and X.F. Liu, A Kind of Process and Equipment for Fabricating Cupronickel Pipes with Heating-Cooling Combined Mold Casting, Chinese Patent, Appl. 201010501407.4, 2010.

W.D. Griffiths and R. Kayikci, The effect of varying chill surface roughness on interfacial heat transfer during casting solidification, J. Mater. Sci., 42(2007), No.11, p.4036.

J.C. Ning, R. Zhu, K. Dong, and C.F. Zhou, Study on solidification of round billet horizontal continuous casting and quality of casting blank, J. Univ. Sci. Technol. Beijing (in Chinese), 31(2009), Suppl.1, p.168.

W. Li, G.S. Zhu, W.J. Wang, and X.H. Wang, Measurement of liquid core length of continuously cast slabs, J. Univ. Sci. Technol. Beijing (in Chinese), 25(2003), No. 4, p.315.

X.N. Meng, M.Y. Zhu, and N.L. Cheng, Formation mechanism of oscillation marks and optimization of oscillation parameters for slab continuous casting with high casting speed, Acta Metall. Sin., 43(2007), No.8, p.839.

A.Y. Deng, E.G. Wang, and J.C. He, Effect of structure parameters on power and magnetic field in electromagnetic soft-contact continuous casting, J. Iron Steel Res. Int., 15(2008), No.1, p.19.

X.T. Li, Q.L. Li, T.J. Li, Y.Q. Song, J.L. Zhang, and J.Z. Jin, Effect of electromagnetic field on surface quality, macrostructure and property of horizontal continuous casting of copper hollow billet, Chin. J. Nonferrous Met., 14(2004), No.12, p.2060.

Author information

Authors and Affiliations

Corresponding author

Additional information

[This work was financially supported by the National High Technology Research and Development Program of China (No.2011BAE23B00)]

Rights and permissions

About this article

Cite this article

Mei, J., Liu, Xh. & Xie, Jx. Microstructure and mechanical properties of BFe10 cupronickel alloy tubes fabricated by a horizontal continuous casting with heating-cooling combined mold technology. Int J Miner Metall Mater 19, 339–347 (2012). https://doi.org/10.1007/s12613-012-0561-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-012-0561-y