Abstract

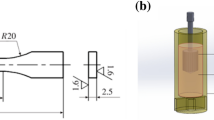

The effect of Mg and Si additon to Al matrix on infiltration kinetics and rates of Al alloys pressureless infiltration into porous SiCp preform was investigated by observing the change of infiltration distance with time as the Al alloys infiltrate into SiCp preforms at different temperatures. The results show that infiltration of SiCp preforms by Al melt is a thermal activation process and there is an incubation period before the infiltration becomes stable. With the increase of Mg content in the Al alloys from 0wt% to 8wt%, the infiltration will become much easier, the incubation period becomes shorter and the infiltration rate is faster, but these effects are not obvious when the Mg content is higher than 8wt%. As for Si addition to the Al alloys, it has no obvious effect on the incubation period, but the infiltration rate increases markedly with the increase of Si content from 0wt% to 12wt% and the rate has no obvious change when the content is bigger than 12wt%. The effect of Mg and Si on the incubation period is related to the infiltration mechanism of Al pressureless infiltration into SiCp preforms and their impact on the infiltration rate is a combined result from viscosity and surface tension of Al melt and SiC-Al wetting ability.

Similar content being viewed by others

References

C.H. Zweben, Advances in high-performance thermal management materials: a review, J. Adv. Mater., 39(2007), p.3.

M.I. Pech-Canul, R.N. Katz, and M.M. Makhlouf, Optimum parameters for wetting silicon carbide by aluminum alloys, Metall. Mater. Trans. A, 31(2000), No.2, p.565.

H.S. Lee, K.Y. Jeon, and H.Y. Kim, Fabrication process and thermal properties of SiCp/Al metal matrix composites for electronic packaging applications, J. Mater. Sci., 35(2000), No.24, p.6231.

J.M. Molina, E. Piñero, J. Narciso, et al., Liquid metal infiltration into ceramic particle preforms with bimodal size distributions, Curr. Opin. Solid State Mater. Sci., 9(2005), No.4–5, p.202.

J.M. Molina, R.A. Saravanan, R. Arpón, et al., Pressure infiltration of liquid aluminium into packed SiC particulate with a bimodal size distribution, Acta Mater., 50(2002), No.2, p.247.

M.I. Pech-Canual, R.N. Katz, and M.M. Makhlouf, Optimum conditions for pressureless infiltration of SiCp preforms by aluminum alloys, J. Mater. Process. Technol., 108(2000), No.1, p.68.

J.W. Liu, Z.X. Zheng, J.M. Wang, et al., Pressureless infiltration of liquid aluminum alloy into SiC preforms to form near-net-shape SiC/Al composites, J. Alloys Compd., 465(2008), No.1–2, p.239.

J.C. Chen, C.Y. Hao, and J.S. Zhang, Fabrication of 3D-SiC network reinforced aluminum-matrix composites by pressureless infiltration, Mater. Lett., 60(2006), No.20, p.2489.

F. Ortega-Celaya, M.I. Pech-Canul, J. López-Cuevas, et al., Microstructure and impact behavior of Al/SiCp composites fabricated by pressureless infiltration with different types of SiCp, J. Mater. Process. Technol., 183(2007), No.2–3, p.368.

M. Montoya-Dávila, M.I. Pech-Canul, and M.A. Pech-Canul, Effect of SiCp multimodal distribution on pitting behavior of Al/SiCp composites prepared by reactive infiltration, Powder Technol., 195(2009), No.3, p.196.

J.C. Lee, J.Y. Byun, S.B. Park, et al., Prediction of Si contents to suppress the formation of Al4C3 in the SiCp/Al composite, Acta Mater., 46(1998), No.5, p.1771.

S.B. Ren, X.H. Qu, and X.B. He, Microstructure changes and mechanism of Al alloy pressureless infiltration into porous SiC preform, J. Mater. Eng., 2009, Suppl.1, p.1.

Y.J. Liang and Y.C. Che, Data Manual of Thermodynamics of Inorganic Substance, Northeastern University Press, Shenyang, 1993, p.35.

Q.H. Hou, R. Mutharasan, and M. Koczak, Feasibility of aluminium nitride formation in aluminum alloys, Mater. Sci. Eng. A, 195(1995), p.121.

A. Contreras, V.H. López, and E. Bedolla, Mg/TiC composites manufactured by pressureless melt infiltration, Scripta Mater., 51(2004), No.3, p.249.

G.P. Martins, D.L. Olson, and G.R. Edwards, Modeling of infiltration kinetics for liquid metal processing of composites, Metall. Trans. B, 19(1988), No.1, p.95.

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was financially supported by the National Natural Science Foundation of China (No.51004010) and the Research Fund for the Doctoral Program of Higher Education of China (No.20090006120022).

Rights and permissions

About this article

Cite this article

Ren, Sb., Shen, Xy., Qu, Xh. et al. Effect of Mg and Si on infiltration behavior of Al alloys pressureless infiltration into porous SiCp preforms. Int J Miner Metall Mater 18, 703–708 (2011). https://doi.org/10.1007/s12613-011-0500-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-011-0500-3