Abstract

Copper (Cu)-bearing stainless steel has testified its effectiveness to reduce the risk of bacterial infections. However, its antibacterial mechanism is still controversial. Therefore, three 430 ferritic stainless steels with different Cu contents are selected to conduct deeper research by the way of bacterial inactivation from two aspects of material and biology. Hereinto, electrochemical and antibacterial results show that the increase in Cu content simultaneously improves the corrosion resistance and antibacterial property of 430 stainless steel. In addition, it is found that Escherichia coli (E. coli) on the surface 430 Cu-bearing stainless steel by the dry method of inoculation possesses a rapid inactivation ability. X-ray photoelectron spectroscopy (XPS) aids with ion chelation experiments prove that Cu (I) plays a more crucial role in the contact-killing efficiency than Cu (II), resulting from more production of reactive oxygen species (ROS).

Graphical abstract

摘要

含铜不锈钢已被证实能够有效地降低细菌感染所带来的风险。然而, 关于其抗菌机制仍存在争议。因此, 我们选择3种不同铜含量的430铁素体不锈钢, 通过细菌灭活的方法, 从材料学和生物学两个方面进行深入的研究。电化学和抗菌实验结果表明, 铜含量的增加同时提高了430不锈钢的耐蚀性能和抗菌性能。此外, 通过干法接种技术发现大肠杆菌在430含铜不锈钢表面可以快速的被灭活。XPS结合离子螯合实验证明, 由于Cu (I)可以促进产生更多的活性氧(ROS), 因此在接触杀灭过程中Cu (I)比Cu (II)起着更为重要的作用。

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

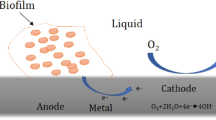

In recent years, some major public health events such as COVID-19, SARS and avian influenza are closely related to microbial contamination, posing a serious threat to human health and even a serious impact on the development of national and global economic construction [1, 2]. It is well known that Escherichia coli (E. coli) can induce serious bacterial infection frequently appearing at open wound [3, 4]. Hereinto, formation of the bacterial biofilm usually enhances the drug resistance against antibiotic, and the usage of antibiotic is a general method to treat bacterial infection. In addition, E. coli widely existing in daily life environment also causes other human illnesses due to its strong infectivity [5]. So, it is meaningful to develop the antibacterial materials especially antibacterial metal material, which possesses a character of structural and functional integration. Cu is also an indispensable trace element of numerous organisms and an important bactericidal element [6, 7]. Cu-bearing stainless steels have been proven to possess a broad-spectrum antibacterial performance and excellent mechanical properties due to the addition of the intrinsic antibacterial-activity of Cu in the steels [8,9,10,11]. Of note, 430 ferritic stainless steel is widely used in washing machine drums, indoor panels and kitchen facilities due to its good machining performance, stress corrosion resistance and low cost [12,13,14,15]. Therefore, the addition of Cu in 430 ferritic stainless steel is expected to improve the antibacterial properties of the material and further broaden its application fields.

However, recent results about the antibacterial mechanism of Cu-bearing stainless steel were still controversial. Traditional view considered that the release of Cu ions originated from Cu-rich precipitation in the stainless steel is the main antibacterial mechanism [16,17,18]. However, it is more contradictory that the released concentration of Cu ions is far less than the minimal inhibitory concentration (MIC). Recently, Zhang et al. [19] found that the degree of direct contact between bacteria and the surface of Cu-bearing martensitic stainless steel regulated the sterilization process of bacteria. Nevertheless, for the Cu-bearing ferritic stainless steel, the study about its antibacterial mechanism is not enough.

In this work, the antibacterial efficiency of a Cu-bearing ferritic stainless steel against E. coli was studied from the perspective of contact killing. Valance state of Cu ions on the metal surface and reactive oxygen species (ROS) level were focused to investigate the antibacterial mechanism of Cu-bearing ferritic stainless steel. The results will be helpful to promote the further development of antibacterial stainless steels.

2 Experimental

2.1 Materials and preparation of specimens

The experimental 430 stainless steel (SS) and 430-Cu SS specimens with dimensions of 10 mm × 10 mm × 5 mm used in this study were provided by TISCO (TAIYUAN IRON & STEEL (GROUP) Co., Ltd., China). Table 1 lists their compositions. The specimens were solution treated at 800 °C for 30 min, followed by air quenching. Subsequently, to obtain the Cu-rich precipitation in 430-Cu SS, the specimens were aged at 550 °C for 60 min, followed by air quenching [20]. Ultimately, the specimens were sequentially ground by silicon carbide papers (SiC) from 150 to 1000 grit. For the following experiments, the specimens were disinfected by 75% ethyl alcohol for 20 min in an ultrasonic bath and were exposed to ultraviolet (UV) light for 20 min to standardize the surface conditions.

2.2 Electrochemical measurements

Electrochemical tests including open-circuit potential (OCP), potentiodynamic polarization (PD) and electrochemical impendence spectroscopy (EIS) in 3.5% NaCl solution were performed to evaluate the corrosion resistance of the experimental steels. Potentiostat/galvanostat (Reference 600TM, Gamry Instruments, Inc., USA) with three-electrode cells was used to conduct these experiments at 24 °C. Thereinto, the tested specimens as the working electrode with a contact area of 1 cm2 were sealed by silicone rubber to avoid crevice corrosion. A saturated calomel electrode (SCE) and a platinum electrode (PE) were employed as the reference electrode and the counter electrode, respectively. OCP was firstly operated for 3600 s to maintain the chemical stability of specimens. Afterward, EIS with a frequency from 0.01 to 100,000 Hz and an amplitude sinusoidal signal of 5 mV was measured to evaluate the corrosion resistance of passive film, and relevant values were derived by ZSimpWin 3.10 software. PD with a scan rate of 0.33 mV·s−1 and a potential from −0.5 to 2.0 VSCE was simultaneously implemented to compare the corrosion resistance of the Cu-bearing 430 steel with the contract steel. Each specimen was tested at least three times to ensure reproducibility of the above measurements.

2.3 Bacterial strains and medium

In this work, Gram-negative bacteria ATCC25922 (Escherichia coli) was purchased from Microbial Culture Collection Centre, Guangdong Institute of Microbiology, China. A Luria–Bertani (LB) medium with pH = 7.2 ± 0.2 was used to culture the above bacterial strains at a humidity thermo-tank with a relative moisture of 70% at 37 °C for 24 h. A beef extract peptone medium consisting of NaCl (5.0 g), peptone (10.0 g), beef extract (5.0 g), agar (20.0 g) and distilled water (1 L) was used to provide the nutrient substance for bacterial survival, and the pH value of medium was adjusted to be 7.2–7.4. Prior to experiments, all the laboratory supplies were sterilized at 121 °C for 20 min in a high-pressure steam sterilization pot.

2.4 Antibacterial activity

Plate counting method was adopted to assess the antibacterial performance of the experimental materials [21]. First, the concentration of bacterial suspension was monitored by the optical density (OD) at a wavelength of 600 nm using an ultraviolet spectrophotometer (752 N, INESA), and then, the bacterial suspension was serially diluted with PBS solution from initial 1 × 108 to 1 × 103 colony forming units (CFU)·ml−1. Subsequently, for the aim of ensuring that the bacterial suspension was well spread out on the surfaces of specimens, the specimens were placed into a 24-pore plate and inoculated with 50 μl bacterial suspension with bacterial concentration of 1 × 106 CFU·ml−1 at 37 °C and relative moisture of 70% for 24 h. Then, the inoculated specimens were put into centrifuge tubes with 2.5 ml PBS for each and oscillated by a vortex oscillator for 40 s. Afterward, 100 μl of the oscillated bacterial suspension was dropped onto the agar plates, which was co-cultured with beef extract peptone medium for 24 h, respectively. The antibacterial rate was calculated by the following formula:

where A denotes the antibacterial rate, ACG is the number of bacterial colonies on the surface of 430 SS, and AEG is the number of bacterial colonies on the surface of 430-Cu SS. At least three duplicate experiments were performed for each specimen.

2.5 Measurement of contact killing on material surfaces

Two antibacterial methods including dry plating and wet plating with the same colony forming units (CFU) were adopted to assess the contact killing mechanism of the Cu-bearing 430 ferritic stainless steel. 5 μl bacterial suspension with concentration of ~ 1 × 107 CFU·ml−1 and 50 μl bacterial suspension with concentration of approximately 1 × 106 CFU·ml−1 were applied for the dry and wet plating studies, respectively. Other detailed operation procedures were described before in the plate counting method.

2.6 Morphology observations by SEM

Scanning electron microscope (SEM, Hitachi, S-3400 N) with a coupled backscattered electrons detector was applied to observe the morphologies of bacterial adhesion on the material surfaces. The bacterial suspensions on the material surfaces were washed off with PBS solution three times. Afterward, the specimens were immersed in 2.5% glutaraldehyde at 4 °C for 4 h, separately sequential dehydrated with 1 ml ethanol with different concentrations (50%, 60%, 70%, 80%, 90%, 95%, 100%) for 20 min to immobilize the biofilms on the material surfaces [22, 23]. Ultimately, the specimens were dried at room temperature ((22 ± 2) °C) for 24 h and sputtered with conductive gold coating.

2.7 Live/dead staining

A live/dead staining, LIVE/DEAD® BacLight TM Bacterial Viability Kit (L7012, USA), was employed to detect the biologically active/inactive bacteria and evaluate their membrane damages on material surfaces. The kit contained two nucleic acid stains: red fluorescent propidium iodide (PI) stain and green fluorescent SYTO-9 stain. First, the inoculated bacterial suspension on the material surfaces was removed and rinsed with PBS solution three times. Then, the sessile bacteria were stained by dripping 20 μl kit (SYTO-9/PI) and 1 ml PBS in a humid and dark environment at 37 °C for 20 min. The specimens were dried and transferred onto microslides immediately, and observed by a confocal laser scanning microscopy (CLSM, MTC-600, USA). Among them, the damaged membrane penetrated by PI showed fluorescent red with wavelength of 514 nm, while the intact membrane penetrated by SYTO-9 showed fluorescent green with wavelength of 488 nm [24]. In addition, the operations of CLSM were carried out in a dark environment. NIS-Elements Viewer software was used to capture three-dimensional images.

2.8 Assay of Cu ions chelation

Cu (I) and Cu (II) on the surfaces of 430-Cu SS were chelated by bathocuproine disulfonic acid (BCS) with an adequate concentration of 5 mmol·L−1 and ethylene diamine tetraacetic acid (EDTA) with an adequate concentration of 10 mmol·L−1, respectively [25]. The bacterial suspension including PBS solution and different aliquot containing the chelators were subsequently inoculated on the surface of the specimens by dry plating method for 40, 80 and 120 min. Eventually, the result was determined by the calculation of antibacterial rate.

2.9 XPS test

X-ray photoelectron spectroscopy (XPS) with an equipment of ESCALAB 250 (Thermo Vacuum Generator, America) surface analysis system was performed to further analyze the chemical compositions and elemental valance on the surface of 430-Cu SS. The material surfaces were irradiated by a monochromatic source (an Al Kα line of 1486.6 eV excitation energy) from a twin Mg/Al anode operating at 150 W. The angle between analyzer and specimens was kept at 90º, and the etching rate was 0.1 nm·s−1. The spectra were analyzed by XPS peak software.

2.9.1 Determination of ROS

ROS Assay Kit (Beyotime, China) was employed to detect the intracellular ROS of E. coli on the material surfaces [26]. After incubated with E. coli for 2 h, the samples were gently rinsed twice with PBS, whereafter 1 ml PBS containing 10 μmol·L−1 2′,7′-dichlorodi-hydrofluorescein diacetate (DCFH-DA) was added onto the specimens, which was co-cultured at 37 °C for 30 min in a humid and dark environment, while 1 ml PBS containing 50 mg·ml−1 Rosup was added to the positive control group. Eventually, CLSM with excitation wavelength of 488 nm and emission wavelength of 525 nm was employed to capture the fluorescence images.

3 Results and discussion

3.1 Electrochemical characteristics

Figure 1a shows dynamic potential polarization curves of 430-Cu SS with different Cu contents; the corresponding electrochemical parameters including corrosion current density (icorr) and corrosion potential (Ecorr) were fitted by Gamry Echem Analyst™ software, as shown in Table 2. In general, icorr and Ecorr values can reflect the corrosion resistance of the material. A smaller icorr indicates a lower corrosion rate and a good corrosion resistance, while Ecorr represents thermodynamic tendency of the corrosion reaction, and a larger Ecorr means a higher corrosion resistance [27, 28]. Figure 1a clearly shows that Ecorr of 430-Cu SS demonstrated an increased tendency with the increase in Cu content, and icorr of 430-Cu SS has an opposite trend. Meanwhile, the data in Table 2 confirm that 430-Cu SS has a relatively low Ecorr and a higher icorr, indicating that its corrosion tendency is weaker than that of the ordinary 430 SS. In particular, when the Cu content reached 1.94%, the icorr value dropped to a minimum of 0.0705 μA·cm−2, while the icorr of 430 SS was 4.8 times higher than that of 430–3 SS, hinting that Cu addition improved the corrosion resistance of 430 SS to a large extent.

Possible reason for improvement of the corrosion resistance is attributed to the formation of a dense and stable passivation film on the surface of 430-Cu SS [29, 30]. The passivation film is mainly composed of metal oxide, which reduces the electrochemical reaction rate by blocking the transfer of electrons, and effectively prevents the invasion of corrosion reactants and highly permeable ions [31, 32]. Figure 1b, c shows Nyquist diagram and Bode diagram of 430-Cu SS obtained by EIS analysis, where Z′ and Z″ represent real part and imaginary part of impedance, |Z| and f represent impedance amplitude and frequency, respectively. In general, a larger arc radius in Nyquist diagram means a greater polarization resistance and a lower corrosion rate [33, 34]. As shown in Fig. 1b, the capacitance arcs gradually enlarged with the increase in Cu content in 430 SS, indicating that the addition of Cu plays a crucial role in inhibiting the occurrence of corrosion reaction. As depicted in Fig. 1c, the Bode diagram shows the same trend that the impedance gradually increased with the Cu content and the peak value of phase angle increased slightly. Besides, it can also be found that the phase angle diagrams of both 430 SS and 430-1 SS showed a single symmetrical phase angle peak; therefore, it only contains one time constant. However, the 430-2 and 430-3 SS appeared a broad asymmetrical peak in the mid-to-low frequency range (< 10 Hz), showing a superposition of at least two times constants. To further quantify EIS data, the ZSimpwin® software was used to generate the equivalent electrical circuit (EEC) combined with physical model of Rs(QpRp) and Rs(QpRp(QdlRct)) (Fig. 1d, e) and fitting physical parameters are shown in Table 2. Among them, Rs is the solution resistance, Rp is the film resistance of deposition of copper corrosion products and passivation film, Rct is the charge transfer resistance, Qp and Qdl represent the capacitor of passivation film and electrical double-layer, respectively. In Table 2, the solution resistances had no obvious difference. The change of total resistance (Rt) can reflect the corrosion behavior of material. As shown in Table 2, the Cu addition obviously improved the polarization resistance of 430 SS, hinting an enhanced corrosion resistance.

3.2 Antibacterial performance

Figure 2a shows the antibacterial rate (A) of the experimental stainless steels against E. coli, and the corresponding representative bacterial colony images are shown in Fig. 2b. It can be seen from Fig. 2a, b that the antibacterial rate of 430-Cu SS had an evident enhancement from initial ~ 60% to 99.9% with the increase in Cu content from 0.99% to 1.94%, showing a certain antibacterial activity. This is because higher Cu content increased the volume fraction of Cu-rich precipitation which benefits the release of Cu ions from the surface of SS and displays satisfactory antibacterial performance finally.

3.3 Dry plating method enhancing antibacterial effect

Previous experiments have confirmed that Cu content has an important effect on the antibacterial performance of 430-Cu SS. However, according to the previous studies, concentration of the released Cu ions is far less than the minimum inhibitory concentration of Cu ions against E. coli. Hence, the release of Cu ions from the surface of Cu-bearing SS as a main antibacterial mechanism is controversial. Instead, the mechanism of contact killing is receiving more attention in recent years [35,36,37,38]. In this work, both dry and wet inoculations were employed to regulate the degree of contact between bacteria and 430-Cu SS. As described in Fig. 3a, there is a significant difference in antibacterial performance between assessments by dry and wet methods in a short time. Using the dry plating method, the number of E. coli colonies on the material surface decreased significantly after 40-min inoculation. The antibacterial rate of 430-Cu SS after 2-h inoculation with E. coli was up to 99%. As shown in Fig. 3b, there were almost no bacterial colonies on the culture plate. In contrast, plenty of E. coli colonies were observed in the assessment by wet method after 2-h inoculation, with antibacterial rate of only 58.97%. In short, the results showed that the antibacterial efficiency assessed by dry method was always higher than that by wet method for a fixed inoculation time. Compared with the wet inoculation, the contact of bacteria with 430-Cu SS surface in the dry inoculation was more direct and continuous, and the extension of inoculation time further promoted the direct contact and the release of Cu ions, greatly enhancing the antibacterial efficiency of 430-Cu SS.

3.4 Visualization of antibacterial performance on material surface

To further elaborate the antibacterial performance of 430-Cu SS, live/dead staining technique coupled with SEM observation was employed to examine the morphology of bacteria on the material surfaces [39]. Figure 4a–d shows SEM images of E. coli attached on the material surfaces after inoculation by dry and wet methods for 2 h, respectively. Only sporadic bacteria with shriveled or cracked morphologies were found on the surface of 430-Cu SS treated by the dry method, as shown in Fig. 4a. As a comparison, a vast majority of E. coli with rod-like and enriched shape attached on the surface of 430 SS, as shown in Fig. 4c. However, compared to the dry method, E. coli inoculated by the wet method had a better active condition no matter the material was 430-Cu SS (Fig. 4b) or 430 SS (Fig. 4d). Above results indicate that 430 SS had no obvious antibacterial activity, but the excellent antibacterial property of 430-Cu SS against E. coli in the condition of dry inoculation was effective. Figure 4e–h shows CLSM images of E. coli on the surfaces of specimens inoculated by dry and wet methods for 2 h, respectively. DNA in all the bacterial cells with intact and impaired membranes was dyed into green by SYTO-9, while PI could only dye the DNA of cells with damaged membranes into red [40]. The surface of 430 SS distributed plenty of green dots, indicating that the membranes of E. coli after contact with 430 SS were integrated. In contrast, plenty of red dots appeared on the surface of 430-Cu SS, illustrating that 430-Cu SS effectively destroyed the membrane structure of E. coli.

a–d SEM images of bacterial attachment on surfaces of specimens after co-incubated with E. coli for 2 h, where images below were partial magnification of red frames; e–h live/dead staining images of bacterial attachment on surfaces of specimens after co-incubated with E. coli for 2 h by different methods

3.5 Influence of Cu ions with different valences

In this work, chelators BCS and EDTA were applied to, respectively, chelate Cu (I) and Cu (II) ions on the surface of 430-Cu SS to clarify the role of different valence Cu ions in the contact killing behavior. As described in Fig. 5a, b, the antibacterial rate presented a dramatically reduction on the chelated surface of 430-Cu SS. Among them, the antibacterial rate after the addition of EDTA was higher than the addition of BCS. The lowest antibacterial activity was achieved when two chelating agents were added. In addition, with the increase in the incubation time, the enhanced antibacterial rate demonstrated that the addition of chelating agents had a certain protective effect on the natural propagation of E. coli. Moreover, this protective effect was more obvious when Cu (I) was chelated, indicating that Cu (I) played more important toxic role in the contact killing efficiency against E. coli than Cu (II).

a Antibacterial rate of 430-Cu SS after co-incubated with E. coli in different chelator solutions by different methods for different time and b corresponding bacterial colonies images on surfaces of specimens; c XPS spectra of Cu 2p3/2 and corresponding percentage of Cu (II); d AES measurement of Cu LMM tested on surface of 430-Cu SS after co-incubated with E. coli for 2 h in different chelator solutions by dry method

In order to further clarify the influence of Cu valence states on the bactericidal ability against E. coli., XPS was applied to analyze the distribution of Cu with different valence states on the surface of 430-Cu SS after co-incubation with E. coli in different chelators addition for 2 h. Figure 5c shows XPS spectra after sputtered for 20 s, in which the characteristic peaks of Cu, Cu (I) and Cu (II) are differentiated at the binding energies of 932.6, 932.5 and 933.5 eV, respectively [41]. The corresponding content of Cu (II) of 430-Cu SS surface was obtained by XPSPEAK, where the contents of Cu (II) in A, B, C and D solutions are 0.69 at%, 2.26 at%, 1.19 at% and 2.37 at%, respectively. It is obvious that the content of Cu (II) gradually increased with the increase of chelating agents, especially the addition of EDTA obviously increased the content of Cu (II). This is because Cu (II) reacted rapidly with EDTA to form complex Cu (II)-EDTA, which restricted the disproportionation reaction of Cu (II) transformation to Cu (I); hence, most of Cu (I) would eventually remain on the surface of 430-Cu SS. Similarly, the addition of BCS directly complexed with Cu (I) and formed Cu (I)-BCS2, resulting in the failure of Cu (I) completely transformed to Cu (II) and leading to a slight increase in Cu (II) content.

However, as the binding energies of Cu and Cu (I) are very close in XPS spectra, it is difficult to accurately distinguish Cu and Cu (I). Therefore, Auger spectra of Cu LMM combined with XPS spectra were used to distinguish Cu and Cu (I) accurately. As shown in Fig. 5d, main peak and satellite peak of Cu LMM are approximately located at 570 and 568 eV, respectively. According to the relevant literature, LMM characteristic peaks of Cu and Cu (I) are located at about 570 and 568 eV, respectively [42]. Therefore, Cu LMM spectra confirmed the existence of Cu and Cu (I) on the surface of 430-Cu SS. In addition, signal strengths of Cu and Cu (I) characteristic peaks were enhanced with the addition of chelating agents, and the characteristic peak intensity of Cu (I) in the Cu LMM spectra after the addition of BCS was significantly stronger than that after the addition of EDTA, which was consistent with the previous experimental results. Above results further confirmed the contributions of Cu (I) and Cu (II) to the contact killing of 430-Cu SS.

3.6 Effect of ROS

As a metabolic by-product of oxygen in cellular respiration, ROS plays a crucial role in maintaining homeostasis and cell signal transduction [43,44,45]. However, a sharp increase in ROS level caused by external influence will lead to the occurrence of oxidative stress in cells, thus causing serious and irreversible damage to cell structure [46, 47]. DCFH-DA is generally used to detect the production level of ROS in the intracellular. As is shown in Fig. 6a, there are plentiful of green fluorescent spots on the positive control group, indicating that a large number of ROS were produced on the surface of 430 SS under the stimulation of Rosup reagent. Figure 6b, c shows the ROS levels of E. coli on the surface of 430-Cu SS after co-incubated by both dry and wet methods for 2 h. Obviously, a few of green fluorescence spots can only be found on the surface of 430-Cu SS co-incubated by wet method under laser confocal microscope, indicating that ROS levels were at a low level on 430-Cu SS. On the contrary, there were many green fluorescence spots on the surface of 430-Cu SS under the condition of dry method, indicating that there were a large amount of ROS on the surface of 430-Cu SS. In addition, almost no green fluorescent spot was found on 430 SS. ROS may be derived from the terminal reactions of respiratory chain substrates [48]. In the process of aerobic respiration of E. coli [49], electrons released by the reaction substrate during oxidation are transferred to oxygen through the respiratory chain, when the received electrons are insufficient, superoxide anions or peroxide groups will be formed, and H2O2 will be generated according to the following reactions:

In general, Cu-rich phases are easy to be oxidized to form Cu ions with different valence states, while Cu ions are unstable and continue to undergo the redox reactions for inter-ions conversion [50], as shown in the following:

Meanwhile, the transition metal ions Cu (I) react with H2O2 under a relatively low toxicity to generate hydroxyl radical with extremely high activity by the Fenton reaction below [51]:

Hydroxyl radicals play an important role in the products of Fenton reaction due to their strong oxidation properties. Since abundant H2O2 is produced during the aerobic respiration of E. coli, a large amount of highly reactive ROS is continuously produced through the Haber–Weiss cycle according to the following two reactions [52]:

The rise in highly active ROS has a higher toxic effect, which can stimulate the death of receptor pathway and cause irreversible cell damage and even apoptosis. Therefore, the above results indicate that the higher the ROS expression level, the higher the sterilization rate of contact killing.

4 Conclusion

In this work, the antibacterial mechanism of Cu-bearing 430 ferritic stainless steel was preliminary studied from the aspects of material and biology. Experimental results indicated that the increase in Cu content effectively improved the corrosion resistance and antibacterial performance of 430-Cu SS. Furthermore, sufficient contact between E. coli and the surface of 430-Cu SS did favor to quick inactivation of bacteria, suggesting that contact killing is the main antibacterial mechanism of 430-Cu SS. In this process, effectively promoting the conversion of Cu ions of Cu-rich phase in the 430-Cu SS matrix and Cu (I) played a more important role than Cu (II) in the bacterial inactivation. In addition, valance transformation of Cu ions generated large amount of ROS, which affected the bacterial cell metabolism and caused bacterial extinction.

References

Liu W, Guan W, Zhong N. Strategies and advances in combating COVID-19 in China. Engineering. 2020;6(10):1076.

Peiris J, Jong D, Guan Y. Avian influenza virus (H5N1): a threat to human health. Clin Microbiol Rev. 2007;40(2):243.

Fleckenstein J, Kuhlmann F. Enterotoxigenic Escherichia coli Infections. Curr Infect Dis Rep. 2019; 21(3):9.

Pitout J. Extraintestinal pathogenic Escherichia coli: a combination of virulence with antibiotic resistance. Front Microbiol. 2012;3(9):9.

Poirel L, Madec J, Lupo A, Schink A, Kieffer N, Nordmann P, Schwarz S. Antimicrobial Resistance in Escherichia coli. Microbiol Spectr. 2018;6(4):289.

Festa R, Thiele D. Copper: an essential metal in biology. Curr Biol. 2011;21(21):R877.

Banci L, Bertini I, Cantini F, Ciofi-Baffoni S. Cellular copper distribution: a mechanistic systems biology approach. Cell Mol Life Sci. 2010;67:2563.

Hans M, Mathews S, Mucklich F, Solioz M. Physicochemical properties of copper important for its antibacterial activity and development of a unified model. Biointerphases. 2016;11(1):018902.

Zhang E, Fu S, Wang R, Wang R, Li H, Liu Y, Ma Z, Liu G, Zhu C, Qin G. Role of Cu element in biomedical metal alloy design. Rare Met. 2019;38:476.

Nan L, Yang K. Cu Ions Dissolution from Cu-bearing antibacterial stainless steel. J Mater Sci Technol. 2010;26(10):941.

Zhan Z, Li X, Cao Y. Design and properties of new Fe-Cu composites. Chin J Rare Met. 2020;44(2):153.

Hastuty S, Nishikata A, Tsuru T. Pitting corrosion of Type 430 stainless steel under chloride solution droplet. Corrosion Sci. 2010;52(6):2035.

Podder AS, Bhanja A. Applications of stainless steel in automobile industry. Adv Mat Res. 2013;794:731.

Wang H, Xiao Z, June Q, Yang H, Cao Z, Guo X. A comparison study on corrosion resistance of 430 stainless steel surfaces modified by alkylsilane and fluoroalkylsilane SAMs. Iron Steel Res Int. 2013;20(12):75.

Cashell KA, Baddoo NR. Ferritic stainless steels in structural applications. Thin-walled Struct. 2014;83:169.

Zhao J, Zhai Z, Sun D, Yang C, Zhang X, Huang N, Jiang X, Yang K. Antibacterial durability and biocompatibility of antibacterial-passivated 316L stainless steel in simulated physiological environment. Mater Sci Eng C. 2019;100:396.

Ni H, Zhang H, Chen R, Zhan W, Huo K, Zuo Z. Antibacterial properties and corrosion resistance of AISI 420 stainless steels implanted by silver and copper ions. Int J Miner Metall Mater. 2012;19(4):322.

Zhang X, Huang X, Yong M, Lin N, Fan A, Tang B. Bactericidal behavior of Cu-containing stainless steel surfaces. Appl Surf Sci. 2012;258(24):10058.

Zhang X, Yang C, Yang K. Contact killing of Cu-bearing stainless steel based on charge transfer caused by the microdomain potential difference. ACS Appl Mater Interfaces. 2020;12(1):361.

Sun S, Zhao A, Zeng Q, Yin H. Effect of continuous annealing temperature on microstructure and properties of ultra-purified ferritic stainless steel. Steel Res Int. 2017;88(7):1600347.

Bartram J, Cotruvo J, Exner M, Fricker C, Glasmacher A. Heterotrophic plate count measurement in drinking water safety management: report of an Expert Meeting Geneva, 24–25 April 2002. Int J Food Microbiol. 2004;92(3):241.

Nan L, Xu D, Gu T, Song X, Yang K. Microbiological influenced corrosion resistance characteristics of a 304L-Cu stainless steel against Escherichia coli. Mater Sci Eng C. 2015;48:228.

Sun Y, Yang C, Yang C, Xu D, Li Q, Yin L, Qiu C, Liu D, Yang K. Stern-Geary constant for X80 pipeline steel in the presence of different corrosive microorganisms, Acta Metall. Sin-Engl Lett. 2019;32(12):1483.

Li M, Nan L, Xu D, Ren G, Yang K. Antibacterial performance of a Cu-bearing stainless steel against microorganisms in tap water. J Mater Sci Technol. 2015;31(3):243.

Laggner H, Hermann M, Gmeiner B, Kapiotics S. Cu2+ and Cu+ bathocuproine disulfonate complexes promote the oxidation of the ROS-detecting compound dichlorofluorescin (DCFH). Anal Bioanal Chem. 2006;385(5):959.

Hicks J, Halkerston R, Silman N, Jackson K, Aylott W. Real-time bacterial detection with an intracellular ROS sensing platform. Biosens Bioelectron. 2019;141:111430.

Xin S, Li M. Electrochemical corrosion characteristics of type 316L stainless steel in hot concentrated seawater. Corrosion Sci. 2014;81:96.

Geng P, Zhao J, Xi T, Yang C, Yang K. Stability of passive film and antibacterial durability of Cu-bearing L605 alloy in simulated physiological solutions. Rare Met. 2020;39(1):1.

Oguzie E, Li J, Liu Y, Chen D, Liu Y, Yang K, Wang F. The effect of Cu addition on the electrochemical corrosion and passivation behavior of stainless steels. Electrochim Acta. 2010;55(17):5028.

Liu X, Liu L, Sui F, Bi H, Chang E, Li M. Influence of Cu on the microstructure and corrosion resistance of cold-rolled type 204 stainless steels. J Solid State Electrochem. 2020;24(1):1197.

Zhou E, Li H, Yang C, Wang J, Xu D, Zhang D, Gu T. Accelerated corrosion of 2304 duplex stainless steel by marine Pseudomonas aeruginosa biofilm. Int Biodeterior Biodegrad. 2018;127:1.

Li P, Zhao Y, Liu Y, Zhao Y, Xu D, Yang C, Zhang T, Gu T, Yang K. Effect of Cu addition to 2205 duplex stainless steel on the resistance against pitting corrosion by the Pseudomonas aeruginosa Biofilm. J Mater Sci Technol. 2017;33(7):723.

Rao V, Singhal L. Corrosion behavior of Cr–Mn–Ni stainless steel in acetic acid solution. Corrosion. 2010;66(8):292.

Rondelli G, Torricelli P, Fini M, Giardino R. In vitro corrosion study by EIS of a nickel-free stainless steel for orthopaedic applications. Biomaterials. 2004;26(7):739.

Mathews S, Kumar R, Solioz M. Copper reduction and contact killing of bacteria by iron surfaces. Appl Environ Microbiol. 2015;81(18):6399.

Mathews S, Hans M, Mucklich F, Solioz M. Contact killing of bacteria on copper is suppressed if bacterial-metal contact is prevented and is induced on iron by copper ions. Appl Environ Microbiol. 2013;79(8):2605.

Santo C, Lam E, Elowsky C, Quaranta G. Bacterial killing by dry metallic copper surfaces. Appl Environ Microbiol. 2011;77(3):794.

Santo C, Taudte N, Nies D, Grass G. Contribution of copper ion resistance to survival of Escherichia coli on metallic copper surfaces. Appl Environ Microbiol. 2008;74(4):977.

Dubravka M, Ruzica A, Branka V, D K, Jelena P, Sara S. Scanning electron microscopy of Listeria monocytogenes biofilms on stainless steel surfaces. Acta Vet beograd. 2009; 59(4):423.

Liu R, Memarzadeh K, Chang B, Zhang Y, Ma Z, Allaker R, Ren L, Yang K. Antibacterial effect of copper-bearing titanium alloy (Ti-Cu) against Streptococcus mutans and Porphyromonas gingivalis. Sci Rep. 2016;6(1):29985.

Ghodselahi T, Vesaghi M, Shafiekhani A, Baghizadeh A, Lameii M. XPS study of the Cu@Cu2O core-shell nanoparticles. Appl Surf Sci. 2008;255(5):2730.

Poulston S, Parlett P, Stone P, Bowker M. Surface oxidation and reduction of CuO and Cu2O studied using XPS and XAES. Surf Interface Anal. 1996;24(12):811.

Forrester S, Kikuchi D, Hernandes M, Xu Q, Griendling K. Reactive oxygen species in metabolic and inflammatory signaling. Circ Res. 2018;122(6):877.

Hensley K, Robinson K, Gabbita S, Salsman S, Floyd R. Reactive oxygen species, cell signaling, and cell injury, Free Radic. Biol Med. 2000;28(10):1456.

Czaja M. Cell signaling in oxidative stress-induced liver injury. Semin Liver Dis. 2007;27(4):378.

Van B, Dat J. Reactive oxygen species in plant cell death. Plant Physiol. 2006;141(2):384.

Prasad K, Dhar I. Oxidative stress as a mechanism of added sugar-induced cardiovascular disease. Int J Angiol. 2014;23(4):217.

Yun S, Oh H, Rhee S, Yoo Y. Regulation of reactive oxygen species generation in cell signaling. Mol Cells. 2011;32(6):491.

Coyle C, Martinez L, Coleman M, Spitz D, Weintraub N, Kader K. Mechanisms of H2O2-induced oxidative stress in endothelial cells, Free Radic. Bio Med. 2006;40(12):2206.

Stohs SJ, Bagchi D. Oxidative mechanisms in the toxicity of metal ions, Free Radic. Bio Med. 1995;18(2):321.

Sun Y, Tian P, Ding D, Yang Z, Han Y. Revealing the active species of Cu-based catalysts for heterogeneous Fenton reaction. Appl Catal B Environ. 2019;258:117985.

Koppenol W. The Haber-Weiss cycle—70 years later. Redox Rep. 2001;6(4):229.

Acknowledgements

This work was financially supported by the National Key Research and Development Program of China (No. 2016YFB0300205) and the Youth Innovation Promotion Association CAS (No. 2018221).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhang, Z., Zhang, XR., Jin , T. et al. Antibacterial mechanism of Cu-bearing 430 ferritic stainless steel. Rare Met. 41, 559–569 (2022). https://doi.org/10.1007/s12598-021-01751-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-021-01751-y