Abstract

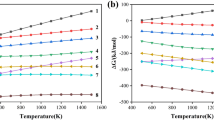

The kinetics of the decomposition of acid dissolved titanium slag with a sodium hydroxide system under atmospheric pressure was studied. The effect of reaction temperature, particle size and NaOH-to-slag mass ratio on titanium extraction was investigated. The results show that temperature and particle size have significant influence on titanium extraction. The experimental data of titanium extraction show that the shrinking core model with chemical reaction controlled process is most applicable for the decomposition of slag, with an apparent activation energy of 62.4 kJ·mol−1. Approximately 85 wt.%−90 wt.% of the titanium can be extracted from the slag under the optimal conditions. In addition, the purity of titanium dioxide obtained in the product is up to 98.5 wt.%.

Similar content being viewed by others

References

Chernet T., Applied mineralogical studies on Australian sand ilmenite concentrate with special reference to its behavior in the sulphate process, Miner. Eng., 1999, 12(5): 485.

Jabłoński M. and Przepiera A., Kinetic model for the reaction of ilmenite with sulphuric acid, J. Therm. Anal. Calorim., 2001, 65(2): 583.

Krchma I.J. and Schaumann H.H., Production of Titanium Dioxides, U.S. Patent, 2559638, 1951.

Mackey T.S., Acid leaching of ilmenite into synthetic rutile, Ind. Eng. Chem., 1974, 13(1): 9.

Sasikumar C., Rao D.S., Srikanth S., Ravikumar B., Mukhopadhyay N.K., and Mehrotra S.P., Effect of mechanical activation on the kinetics of sulfuric acid leaching of beach sand ilmenite from Orissa, Hydrometallurgy, 2004, 75(1): 189.

Langmesser P.W., Volz H.G., and Kienast G., Process Leading to the Production of Titanium Dioxide Pigment with a High Degree of Whiteness, U.S. Patent, 3760058, 1973.

Morris A.J., Magyar J.C., Wooten G.D., and Yuill W.A., Method and Apparatus for Production Titanium Dioxide, U.S. Patent, 5840112, 1998.

Sohn H.Y. and Zhou L., The chlorination kinetics of beneficiated ilmenite particles by CO + Cl2 mixtures, Chem. Eng. J., 1999. 72(1): 37.

Xue T.Y., Wang L.N., Qi T., Chu J.L., Qu J.K., and Liu C.H., Decomposition kinetics of titanium slag in sodium hydroxide system, Hydrometallurgy, 2009, 95(1–2): 22.

Pistorius P.C., The relationship between FeO and Ti2O3 in ilmenite smelter slags, Scand. J. Metall., 2002, 31(2): 120.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Feng, Y., Wang, J., Wang, L. et al. Decomposition of acid dissolved titanium slag from Australia by sodium hydroxide. Rare Metals 28, 564–569 (2009). https://doi.org/10.1007/s12598-009-0109-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-009-0109-0