Abstract

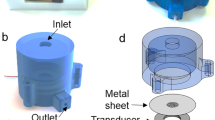

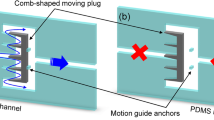

This paper presents a new type of ball valve micro-pumps with much simplified structure design and excellent performance. The key element in this micro-pump is a pair of ball valves implemented by confining a micro-ball within a nozzle. The nozzles are axially symmetrical with a specifically designed profile and are directly fabricated using excimer laser micromachining approaches. The ball valves are integrated with a flow chamber, an electromagnetically actuated PDMS membrane, and a coil. When passing an alternative current (AC) through the coil, the flow chamber is actuated to pump fluid flowing along one direction which is controlled by the ball valves. The performance of the proposed micro-pump is evaluated using an AC voltage in the range of 2-6 V and a frequency of 10-70 Hz. Experimental results show that a maximum flow rate of 389 μL/min and a maximum back pressure of 423 mm-H 2 O are achieved. It offers a low-cost, simple, and effective solution for a wide range of microfluidic pumping applications.

Similar content being viewed by others

References

Pan, T., McDonald, S. J., Kai, E. M., and Ziaie, B., “A Magnetically Driven PDMS Micropump with Ball Check-Valves,” Journal of Micromechanics and Microengineering, Vol. 15, No. 5, pp. 1021–1026, 2005.

Junwu, K., Zhigang, Y., Taijiang, P., Guangming, C., and Boda, W., “Design and Test of a High-Performance Piezoelectric Micropump for Drug Delivery,” Sensors and Actuators A: Physical, Vol. 121, No. 1, pp. 156–161, 2005.

Makino, E., Mitsuya, T., and Shibata, T., “Fabrication of Tini Shape Memory Micropump,” Sensors and Actuators A: Physical, Vol. 88, No. 3, pp. 256–262, 2001.

Zengerle, R., Richter, A., and Sandmaier, H., “A Micro Membrane Pump with Electrostatic Actuation,” Proceedings IEEE Micro Electro Mechanical Systems, pp. 19–24, 1992.

Lammerink, T. S., Elwenspoek, M., and Fluitman, J. H., “Integrated Micro-Liquid Dosing System,” Proceedings IEEE Micro Electro Mechanical Systems, pp. 254–259, 1993.

Lee, Y.-C., Chen, C.-M., and Wu, C.-Y., “A New Excimer Laser Micromachining Method for Axially Symmetric 3D Microstructures with Continuous Surface Profiles,” Sensors and Actuators A: Physical, Vol. 117, No. 2, pp. 349–355, 2005.

Krüger, J., Niino, H., and Yabe, A., “Investigation of Excimer Laser Ablation Threshold of Polymers Using a Microphone,” Applied Surface Science, Vols. 197-198, pp. 800–804, 2002.

Dyer, P., “Excimer Laser Polymer Ablation: Twenty Years on,” Applied Physics A: Materials Science & Processing, Vol. 77, No. 2, pp. 167–173, 2003.

Lee, Y.-C. and Wu, C.-Y., “Excimer Laser Micromachining of Aspheric Microlenses with Precise Surface Profile Control and Optimal Focusing Capability,” Optics and Lasers in Engineering, Vol. 45, No. 1, pp. 116–125, 2007.

Chiu, C.-C. and Lee, Y.-C., “Fabricating of Aspheric Micro-Lens Array by Excimer Laser Micromachining,” Optics and Lasers in Engineering, Vol. 49, No. 9, pp. 1232–1237, 2011.

Chiu, C.-C. and Lee, Y.-C., “Excimer Laser Micromachining of Aspheric Microlens Arrays Based on Optimal Contour Mask Design and Laser Dragging Method,” Optics Express, Vol. 20, No. 6, pp. 5922–5935, 2012.

Chiu, C.-C. and Lee, Y.-C., “Excimer Laser Micromachining of Aspheric Microlens Arrays Based on Optimal Contour Mask Design and Laser Dragging Method,” Optics Express, Vol. 20, No. 6, pp. 5922–5935, 2012.

Braun, A., Zimmer, K., Hösselbarth, B., Meinhardt, J., Bigl, F., and Mehnert, R., “Excimer Laser Micromachining and Replication of 3D Optical Surfaces,” Applied Surface Science, Vols. 127-129, pp. 911–914, 1998.

Chen, R.-H. and Cheng, C.-M., “Study of Spin Coating Properties of SU-8 Thick-Layer Photoresist,” Proc. of SPIE, Vol. 4345, pp. 494–501, 2001.

Chuang, C.-S., Wu, T.-F., Chen, C.-H., Chang, K.-C., Ju, J.-W., et al., “Lab on A Chip for Multiplexed Immunoassays to Detect Bladder Cancer Using Multifunctional Dielectrophoretic Manipulations,” Lab on a Chip, Vol. 15, No. 14, pp. 3056–3064, 2015.

Chuang, C.-H., Wu, H.-P., Huang, Y.-W., and Chen, C.-H., “Enhancing of Intensity of Fluorescence by DEP Manipulations of Polyaniline-Coated Al2O3 Nanoparticles for Immunosensing,” Biosensors and Bioelectronics, Vol. 48, pp. 158–164, 2013.

Park, J. Y., Yoo, S. J., Lee, E.-J., Lee, D. H., Kim, J. Y., and Lee, S.-H., “Increased Poly (Dimethylsiloxane) Stiffness Improves Viability and Morphology of Mouse Fibroblast Cells,” BioChip Journal, Vol. 4, No. 3, pp. 230–236, 2010.

Sunkara, V., Park, D.-K., Hwang, H., Chantiwas, R., Soper, S. A., and Cho, Y.-K., “Simple Room Temperature Bonding of Thermoplastics and Poly (Dimethylsiloxane),” Lab on a Chip, Vol. 11, No. 5, pp. 962–965, 2011.

Shen, M., Yamahata, C., and Gijs, M., “A High-Performance Compact Electromagnetic Actuator for a PMMA Ball-Valve Micropump,” Journal of Micromechanics and Microengineering, Vol. 18, No. 2, Paper No. 025031, 2008.

Nguyen, T. T., Goo, N. S., Nguyen, V. K., Yoo, Y., and Park, S., “Design, Fabrication, and Experimental Characterization of a Flap Valve IPMC Micropump with a Flexibly Supported Diaphragm,” Sensors and Actuators A: Physical, Vol. 141, No. 2, pp. 640–648, 2008.

Yun, K.-S., Cho, I.-J., Bu, J.-U., Kim, C.-J., and Yoon, E., “A Surface-Tension Driven Micropump for Low-Voltage and Low-Power Operations,” Journal of Microelectromechanical Systems, Vol. 11, No. 5, pp. 454–461, 2002.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chien, HL., Lee, YC. A ball valve micro-pump based on axially symmetrical nozzle fabricated by excimer laser micromachining technology. Int. J. Precis. Eng. Manuf. 18, 1315–1320 (2017). https://doi.org/10.1007/s12541-017-0156-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-017-0156-7