Abstract

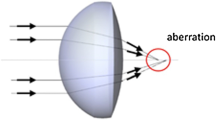

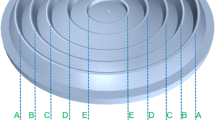

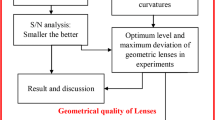

In the present research, the authors investigated the lens manufacturing with the injection molding process by using the geometrical contour errors as the quality criterion. In order to produce functional injection-molded optical components, a special cavity mold was used to perform experimental testing for biconvex spherical lenses and numerical simulation was used to help during mimic of the process behavior. The approach was divided into validation step and optimization step. In the validation step, a reliable numerical model was designed to reproduce material features during filling and shrinkage, in order to correctly evaluate lens deflection. In the optimization step, the Grey Relational Component analysis coupled to the Taguchi Design was used to identify the optimal parameter set leading to the best values of lens total deflection, Peak-to-Valley and Root Mean Square between real and ideal lens surface geometry.

Similar content being viewed by others

References

Cellere, A. and Lucchetta, G., “Identification of CRIMS model parameters for warpage prediction in injection molding simulation,” Int. J. of Material Forming, Vol. 3, No. 1, pp. 37–40, 2010.

Chang, Y.-J., Yu, C.-K., Chiu, H.-S., Yang, W.-H., Lai, H.-E., and Wang, P.-J., “Simulations and verifications of true 3D optical parts by injection molding process,” Proc. of ANTEC, Vol. 22, No. 24, pp. 253–258, 2009.

Hu, G.-H. and Cui, Z.-S., “Effect of Packing Parameters and Gate Size on Shrinkage of Aspheric Lens Parts,” J. of Shanghai Jiaotong Univ. (Sci.), Vol. 15, No. 1, pp. 84–87, 2010.

Kennedy, P. and Zheng, R., “High accuracy shrinkage and warpage prediction for injection molding,” Proc. of ANTEC, Vol. 5, No. 9, pp. 1–7, 2002.

Kim, S. Y., Rim, M. H., Lim, W. S., and Kim, W. Y., “A Numerical Approach for Predicting the Optical Characteristics of Injection-Molded Lenses,” J. of Injection Molding Technology, Vol. 4, No. 1, pp. 29–35, 2000.

Lin, J. C. and Lee, K. S., “Molding analysis of multi-cavity aspheric lens and mold designing,” Advanced Materials Research, Vol. 83–86, pp. 77–87, 2010.

Lu, X. and Khim, L. S., “A statistical experimental study of the injection molding of optical lenses,” J. of Materials Processing Technology, Vol. 113, No. 1–3, pp. 189–195, 2001.

Michaeli, W., Heßner, S., Klaiber, F., and Forster, J., “Geometrical Accuracy and Optical Performance of Injection Moulded and Injection-compression Moulded Plastic Parts,” CIRP Annals — Manufacturing Technology, Vol. 56, No. 1, pp. 545–548, 2007.

Michaeli, W. and Forster, J., “Production of polymer lenses using injection molding,” J. of Polymer Engineering, Vol. 26, No. 2–4, pp. 133–146, 2006.

Montgomery, D. C., “Response surface method and other other approaches to process optimization,” Design and Analysis of Experiments, 5th Ed., pp. 427–510, 2000.

Park, K. and Joo, W., “Optical simulation of a plastic lens reflecting injection molding effects,” Proc. of ANTEC, Vol. 1, No. 5, pp. 561–565, 2005.

Park, H.-S. and Dang, X.-P., “Optimization of conformal cooling channels with array of baffles for plastic injection mold,” Int. J. Precis. Eng. Manuf., Vol. 11, No.6, pp. 879–890, 2010.

Pazos, M., Baselga, J., and Bravo, J., “Limiting thickness estimation in polycarbonate lenses injection using CAE tools,” J. of Materials Processing Technology, Vol. 143, No. 144, pp. 438–441, 2003.

Shieh, J.-Y., Wang, L., and Ke, S.-Y., “A Feasible Injection Molding Technique for the Manufacturing of Large Diameter Aspheric Plastic Lenses,” Optical Review, Vol. 17, No. 4, pp. 399–403, 2010.

Tsai, K.-M., Hsieh, C.-Y., and Lo, W.-C., “A study of the effects of process parameters for injection molding on surface quality of optical lenses,” J. of Materials Processing Technology, Vol. 209, No. 7, pp. 3469–3477, 2009.

Turng, L.-S., Peic, M., and Bradley, D. K., “Process Simulation and Optimization for Injection Molding-Experimental Verifications and Field Applications,” J. of Injection Molding Technology, Vol. 6, No. 2, pp. 143–155, 2002.

Wang, C. H., “Dynamic multi-response optimization using principal component analysis and multiple criteria evaluation of the grey relation model,” Int. J. of Advanced Manufacturing Technology, Vol. 5, No. 6, pp. 617–624, 2007.

Wang, P. J. and Lai, H. E., “Study of residual birefringence in injection molded lenses,” Proc. of ANTEC, Vol. 6, No. 10, pp. 2494–2498, 2007.

Wen, J. and Wen, P., “The simulation and optimization of aspheric plastic lens injection molding,” J. of Wuhan University of Technology (Mat. Sci.), Vol. 20, No. 2, pp. 86–89, 2005.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Spina, R., Walach, P., Schild, J. et al. Analysis of lens manufacturing with injection molding. Int. J. Precis. Eng. Manuf. 13, 2087–2095 (2012). https://doi.org/10.1007/s12541-012-0276-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-012-0276-z