Abstract

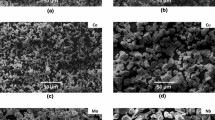

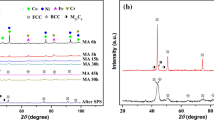

In this paper, FeSiBAlNiCox (x = 0.2, 0.8) high-entropy alloy (HEA) powders were fabricated by mechanical alloying process, and the powders milled for 140 h were sintered by spark plasma sintering (SPS) technique. The microstructures and properties of as-milled powders and as-sintered samples were investigated. The results reveal that the final milling products (140 h) of both sample powders present the fully amorphous structure. The increased Co contents obviously enhance the glass forming ability and thermal stability of amorphous HEA powders, which are reflected by the shorter formation time of fully amorphous phase and the higher onset crystallization temperature, respectively. According to coercivity, the as-milled FeSiBAlNiCox (x = 0.2, 0.8) powders (140 h) are the semi-hard magnetic materials. FeSiBAlNiCo0.8 HEA powders possess the highest saturation magnetization and largest remanence ratio. The SPS-ed products of both bulk HEAs are composed of body-centered cubic solid solution, and FeSi and FeB intermetallic phases. They possess the high relative density above 97% and excellent microhardness exceeding 1150 HV. The as-sintered bulks undergo the remarkable increase in saturation magnetization compared with the as-milled state. The SPS-ed FeSiBAlNiCo0.8 HEA exhibits the soft magnetic properties. The electrochemical corrosion test is carried out in 3.5% NaCl solution. The SPS-ed FeSiBAlNiCo0.2 HEA reveals the better passivity with low passive current density, and the higher pitting resistance with wide passive region.

Similar content being viewed by others

References

L. Lilensten, J.P. Couzinie, L. Perriere, J. Bourgon, N. Emery, I. Guillot, Mater. Lett. 132, 123 (2014)

M. Feuerbacher, M. Heidelmann, C. Thomas, Philos. Mag. 95, 1221 (2015)

Y.J. Zhao, J.W. Qiao, S.G. Ma, M.C. Gao, H.J. Yang, M.W. Chen, Y. Zhang, Mater. Des. 96, 10 (2016)

C.Y. Cheng, J.W. Yeh, Mater. Lett. 185, 456 (2016)

C.Y. Cheng, J.W. Yeh, Mater. Lett. 181, 223 (2016)

Z.Q. Fu, W.P. Chen, H.Q. Xiao, L.W. Zhou, D.Z. Zhu, S.F. Yang, Mater. Des. 44, 535 (2013)

Y. Liu, Y. Zhang, H. Zhang, N.J. Wang, X. Chen, H.W. Zhang, Y.X. Li, J. Alloys Compd. 694, 869 (2017)

S. Varalakshmi, G.A. Rao, M. Kamaraj, B.S. Murty, J. Mater. Sci. 45, 5158 (2010)

S. Varalakshmi, M. Kamaraj, B.S. Murty, Mater. Sci. Eng. A 527, 1027 (2010)

J. Wang, Z. Zheng, J. Xu, Y. Wang, J. Magn. Magn. Mater. 355, 58 (2014)

S. Zhang, C.L. Wu, C.H. Zhang, M. Guan, J.Z. Tan, Opt. Laser Technol. 84, 23 (2016)

A. Poulia, E. Georgatis, A. Lekatou, A.E. Karantzalis, Int. J. Refract. Metals Hard Mater. 57, 50 (2016)

Y.H. Li, W. Zhang, T.L. Qi, J. Alloys Compd. 693, 25 (2017)

P.P. Li, A.D. Wang, C.T. Liu, J. Alloys Compd. 694, 55 (2017)

T.T. Zuo, M.C. Gao, L.Z. Ouyang, X. Yang, Y.Q. Cheng, R. Feng, S.Y. Chen, P.K. Liaw, J.A. Hawk, Yong Zhang, Adv. Mater. 130, 10 (2017)

X.X. Zhu, X. Zhou, S.S. Yu, C.C. Wei, J. Xu, Y. Wang, J. Magn. Magn. Mater. 430, 59 (2017)

K.B. Zhang, Z.Y. Fu, Intermetallics 22, 24 (2012)

Z.G. Zhu, K.H. Ma, Q. Wang, C.H. Shek, Intermetallics 79, 1 (2016)

W.H. Liu, J.Y. He, H.L. Huang, H. Wang, Z.P. Lu, C.T. Liu, Intermetallics 60, 1 (2015)

Q. Zhang, H. Xu, X.H. Tan, X.L. Hou, S.W. Wu, G.S. Tan, L.Y. Yu, J. Alloys Compd. 693, 1061 (2017)

J. Xu, E. Axinte, Z.F. Zhao, Y. Wang, J. Magn. Magn. Mater. 414, 59 (2016)

B. Kang, J. Lee, H.J. Ryu, S.H. Hong, Mater. Sci. Eng. A 712, 616 (2018)

N. Eißmann, B. Klöden, T. Weißgärber, B. Kieback, Powder Metall. 60, 184 (2017)

J.W. Wang, Y. Liu, B. Liu, Y. Wang, Y.K. Cao, T.C. Li, R. Zhou, Mater. Sci. Eng. A 689, 233 (2017)

A. Raphel, S. Kumaran, K.V. Kumar, L. Varghese, Mater. Today 4, 195 (2017)

W.P. Chen, Z.Q. Fu, S.C. Fang, H.Q. Xiao, D.Z. Zhu, Mater. Des. 51, 854 (2013)

C. Wang, W. Ji, Z.Y. Fu, Adv. Powder Technol. 25, 1334 (2014)

O.N. Senkov, G.B. Wilks, J.M. Scott, D.B. Miracle, Intermetallics 19, 698 (2011)

H.L. Wang, T.X. Gao, J.Z. Niu, P.J. Shi, J. Xu, Y. Wang, Int. J. Miner. Metall. Mater. 23, 77 (2016)

J. Xu, C.Y. Shang, W.J. Ge, H.L. Jia, P.K. Liaw, Y. Wang, Adv. Powder. Technol. 27, 1418 (2016)

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, S.Y. Chang, Adv. Eng. Mater. 6, 299 (2004)

Y. Zhang, Y.J. Lin, J.P. Lin, G.L. Chen, P.K. Liaw, Adv. Eng. Mater. 10, 534 (2008)

C.L. Wang, J. Liu, Y. Mudryk, K.A. Gschneidner Jr., Y. Long, V.K. Pecharsky, J. Magn. Magn. Mater. 405, 122 (2016)

X.P. Nie, X.M. Xu, Q.K. Jiang, L.Y. Chen, Y. Xu, Y.Z. Fang, G.Q. Xie, M.F. Luo, F.M. Wu, X.D. Wang, Q.P. Cao, J.Z. Jiang, J. Non-Cryst, Solids 355, 203 (2009)

Acknowledgements

The authors acknowledge financial support from the Natural Science Foundation of China (No. 51671095), and Key Research Development Program of Shandong Province of China (No. 2015GGx102016).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, W., Li, B., Zhai, S. et al. Alloying Behavior and Properties of FeSiBAlNiCox High Entropy Alloys Fabricated by Mechanical Alloying and Spark Plasma Sintering. Met. Mater. Int. 24, 1112–1119 (2018). https://doi.org/10.1007/s12540-018-0047-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-018-0047-1