Abstract

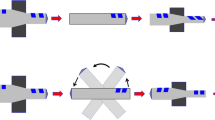

The effect of reduction of area (RA), 10%, 20%, and 30%, during wire drawing on the inhomogeneities in microstructure and mechanical properties along the radial direction of Fe-Mn-Al-C twinning-induced plasticity steel has been investigated. After wire drawing, the deformation texture developed into the major <111> and minor <100> duplex fiber texture. However, the <111> texture became more pronounced in both center and surface areas as the RA per pass increased. It also shows that a larger RA per pass resulted in a higher yield strength and smaller elongation than a smaller RA per pass at all strain levels. Although inhomogeneities in microstructure and mechanical properties along the radial direction decreased with increasing RA per pass, there existed an optimum RA per pass for maximum drawing limit. Insufficient penetration of strain from surface to center at small RA per pass (e.g., 10%) and high friction and unsound metal flow at large RA per pass (e.g., 30%) all resulted in heterogeneous microstructure and mechanical properties along the radial direction of drawn wire. On the other hand, 20% RA per pass improved the drawing limit by about 30% as compared to the 10% and 30% RAs per pass.

Similar content being viewed by others

References

B. Kim, T. T. T. Trang, and N. J. Kim, Met. Mater. Int. 20, 35 (2014).

A. Zargaran, H. S. Kim, J. H. Kwak, and N. J. Kim, Met. Mater. Int. 21, 79 (2015).

D. Jeong, T. Park, J. Lee, and S. Kim, Met. Mater. Int. 21, 453 (2015).

I. C. Yi, Y. Ha, K. H. Kwon, H. Lee, and N. J. Kim, Met. Mater. Int. 21, 461 (2015).

J. Y. Choi, S. W. Hwang, M. C. Ha, and K. T. Park, Met. Mater. Int. 20, 893 (2014).

M. S. Shim, B. C. Suh, J. H. Kim, and N. J. Kim, Met. Mater. Int. 21, 490 (2015).

S. S. Sohn, B. J. Lee, S. Lee, and J. H. Kwak, Met. Mater. Int. 21, 43 (2015).

Y. H. Kim, J. H. Kim, T. H. Hwang, J. Y. Lee, and C. Y. Kang, Met. Mater. Int. 21, 485 (2015).

J. K. Hwang, I. C. Yi, I. H. Son, J. Y. Yoo, B. Kim, A. Zargaran, and N. J. Kim, Mater. Sci. Eng. A, 644, 41 (2015).

T. W. Kim and Y. G. Kim, Mater. Sci. Eng. A 160, L13 (1993).

O. Grassel, L. Kruger, G. Frommeyer, and L. W. Meyer, Int. J. Plast. 16, 1391 (2000).

O. Bouaziz and N. Guelton, Mater. Sci. Eng. A 31-321, 246 (2001).

O. Bouaziz, S. Allain, C. P. Scott, P. Cugy, and D. Barbier, Curr. Opin. Solid State Mater. Sci. 15, 141 (2011).

U. Chakkingal, A. B. Suriadi, and P. F. Thomson, Mater. Sci. Eng. A 266, 241 (1999).

S. K. Hwang, Y. G. Jin, I. H. Son, K. H. Rhee, D. L. Lee, and Y. T. Im, Int. J. Mech. Sci. 53, 479 (2011).

S. K. Hwang, H. M. Baek, J. W. Lee, I. H. Son, Y. T. Im, and C. M. Bae, JMPT 214, 318 (2014).

R. C. Reuter and J. Tranier, Proc. Int. Conf. on Developments in the Drawing of Metals, p.30, The Metals Society, London, UK (1983).

Q. Guo, Y. S. Chun, J. H. Lee, Y. Heo, and C. S. Lee, Met. Mater. Int. 20, 1043 (2014).

A. G. Atkins and R. M. Caddell, Int. J. Mech. Sci. 10, 15 (1968).

R. K. Chin and P. S. Stelf, Int. J. Mach. Tool Manufact. 35, 1087 (1995).

M. T. P. Aguilar, E. C. S. Correa, R. F. Silva, and P. R. Cetlin, JMPT 125-126, 323 (2002).

H. S. Lin, Y. C. Hsu, and C. C. Keh, JMPT 201, 128 (2008).

G. H. Hasani, R. Mahmudi, and A. Karimi-Taheri, Int. J. Mater. Form 3, 59 (2010).

L. Sadok, J. Luksza, and J. Majta, JMPT 44, 129 (1994).

J. Luksza, J. Majta, M. Burdek, and M. Ruminski, JMPT 80-81, 398 (1998).

Z. Muskalski, S. Wiewiorowska, and M. Pelka, Metalurgija 52, 96 (2013).

A. Saeed-Akbari, J. Imlau, U. Prahl, and W. Bleck, Metall. Mater. Trans. A 40, 3076 (2009).

O. Bouaziz, S. Allain, and C. Scott, Scripta Mater. 58, 484 (2008).

Y. Wang, H. Y. Huang, and J. X. Xie, Mater. Sci. Eng. A 530, 418 (2011).

K. Yoshida and K. Doi, Procedia Engineering 81, 706 (2014).

S. M. Byon and S. M. Hwang, Computers and Structures 79, 1363 (2001).

H. S. Kim, M. H. Seo, and S. I. Hong, Mater. Sci. Eng. A 291, 86 (2000).

C. Simsir, P. Karpuz, and C. H. Gur, Comp. Mater. Sci. 48, 633 (2010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hwang, JK., Son, IH., Yoo, JY. et al. Effect of reduction of area on microstructure and mechanical properties of twinning-induced plasticity steel during wire drawing. Met. Mater. Int. 21, 815–822 (2015). https://doi.org/10.1007/s12540-015-5273-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-015-5273-1