Abstract

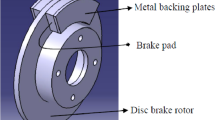

In the case of employing brake discs as a key component of mechanical brake equipment, the initiation of thermal cracking owing to repetitive thermal shock generated during braking may potentially lead to higher maintenance costs, worsened braking performance, and greater risk of railway accidents. The purpose of this study is to gain basic data to facilitate application of compacted vermicular (C. V.) graphite cast iron to brake discs in order to obtain high thermal crack resistance and improved lifetime. To this end, this study developed three types of C. V. graphite cast iron with differing content of key elements, including Ni, Cr, and Mo. Each test specimen underwent numerous tests for evaluation of materials characteristics, and the results were compared with those obtained for existing materials. The test results show that the thermal fatigue lifetime of material C is nearly double that of the conventional material. This demonstrates the suitability of material C as a material for brake discs in mid- to high-speed railway vehicles.

Similar content being viewed by others

References

T. J. Mackin, et al., Eng. Fail. Anal. 9, 63 (2002).

F. Bagnoli, F. Dolce, and M. Bernabei, Eng. Fail. Anal. 16, 152 (2009).

J. Yamabe, et al., JSAE Review 23, 105 (2002).

D. J. Kim, C. S. Seok, J. M. Koo, W. T. We, B. C. Goo, and J. I. Won, Fatigue Fract. Eng. Mater. Struct. 33, 37 (2010).

C.-Y. Kang, D.-H. Jo, Y.-K. Kim, H.-S. Han, H.-W. Lee, and J.-H. Sung, J. Kor. Inst. Met. & Mater. 47, 169 (2009).

A. N. Roviglione and J. D. Hermida, Metall. Mater. Trans. 33B, 235 (2002).

S. W. Kim, S. L. Cockcroft, A. M. Omran, and H. N. Hwang, J. Alloy. Compd. 487, 253 (2009).

S. Dawson and T. Schroeder, AFS Transactions, p. 813–821 (2004).

G. Cueva, A. Sinatora, W. L. Guesser, and A. P. Tschiptschin, Wear 255, 1256 (2003).

S. Dawson and T. Schroeder, AFS Transactions 2004, p. 813–821 (2004).

ISO 945-2 Graphite classification by image analysis (2008).

ASTM E9:89 Standard test methods of compression testing of metallic materials at room temperature (1995).

ISO 1143 Metals — Rotating bar bending fatigue testing (1975).

B. C. Goo and C. H. Lim, 9th International ASTM/ESIS Symposium on Fatigue and Fracture Mechanics (2009).

I. M. Andreiko, O. P. Ostash, and V. V. Papovych, Mater. Sci. 38, 76 (2002).

ISO 16112 Compacted (vermicular) graphite cast irons — Classification (2006).

J. Datsko, Material Properties and Manufacturing Processes, Joseph Datsko Consultants, USA (1966).

D. Holmgren, A. Dioìszegi, and I. L. Svensson, Int. J. Cast Met. Res. 20, 30 (2007).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lim, CH., Goo, BC. Development of compacted vermicular graphite cast iron for railway brake discs. Met. Mater. Int. 17, 199–205 (2011). https://doi.org/10.1007/s12540-011-0403-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-011-0403-x