Abstract

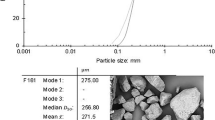

Nowadays, in most of the advanced and developing countries, waste tires have caused serious environmental problems such as fire and environmental contamination. For reusing them in an appropriate and beneficial way, waste tires have been utilized as a lightweight fill material in geotechnical engineering applications such as highway embankments. In this study, Babolsar fine-grained sand and granulated rubber with sizes in the ranges of 1 to 4, 1 to 9, and 4 to 9 mm were used. A series of model footing tests on reinforced sand with different sizes of granulated rubber were carried out. According to the results, 4- to 9-mm granulated rubber had the highest effect on enhancement of bearing capacity and reduction of fine-grained sand settlement. The results showed that sand-granulated rubber mixtures with granulated rubber in the range of 4 to 9 mm and content of 10% by weight of mixture can increase the bearing capacity of sand up to 50%. In addition, for this mixture, a series of laboratory tests were conducted to determine the optimum width and depth of the reinforcement layer consisting of sand-granulated rubber mixture. The results indicate that the optimum width and the most effective depth of this mixture are 5B and 1B, respectively (where B is the footing width).

Similar content being viewed by others

References

Ahmed, I. (1993) Laboratory study of properties of rubber-soils, Final report, Indiana Dept. of Transp., Joint Highway Research Project. Purdue University, West Lafayette, Ind

ASTM D Standard D 698., “Standard proctor compaction test.” ASTM International

ASTM D Standard D 1194-94. , “Standard test method for bearing capacity of soil for static load and spread footings.” ASTM International

ASTM D Standard D 4253. , “Standard test method for maximum index density and unit weight of soils using a vibratory table.” ASTM International

ASTM D Standard D 4254. , “Standard test method for minimum index density and unit weight of soils and calculation of relative density.” ASTM International

Balunaini U, Prezzi M (2010) Interaction of ribbed-metal-strip reinforcement with tire shred–sand mixtures. Geotech Geol Eng 28(2):147–163

Balunaini U, Yoon S, Prezzi M, Salgado R (2014) Pullout response of uniaxial geogrid in tire shred–sand mixtures. Geotech Geol Eng 32(2):505–523

Bosscher PJ, Edil TB, Kuraoka S (1994) Engineering properties of tire chips and soil mixtures. Geotech Test J 17(4):453–464

Bosscher PJ, Edil TB, Kuraoka S (1997) Design of highway embankments using tire chips. J Geotech Geoenviron 123(4):295–304

Bowles, Joseph E. (1979) Physical and geotechnical properties of soils.

Braja, M Das, (1974) Advanced soil mechanics. Principles of geotechnical engineering 5th edition

Briaud JL, Jeanjean P (1994) Load settlement curve method for spread footings on sand. Vertical and Horizontal Deformations of Foundations and Embankments, ASCE 2:1774–1804

Brophy MOR, Graney J (2004) Groundwater effects from highway tire shred use. Environ Forensic 5(2):79–84

Cerato, Amy B. (2005) Scale effects of shallow foundation bearing capacity on granular material. Department of Civil and Environmental Engineering, University of Massachusetts Amherst

Consoli NC, Montardo JP, Prietto PDM, Pasa GS (2002) Engineering behavior of a sand reinforced with plastic waste. J Geotech Geoenviron 128(6):462–472

Debeer, E.E. (1965) Bearing capacity and settlement of foundations. Lecture 3: bearing capacity and settlement of shallow foundations on sand. PP. 15–34

Edil TB, Bosscher PJ (1994) Engineering properties of granulated rubber and soil mixtures. Geotech Test J 17(4):453–464

Foose GJ, Benson CH, Bosscher PJ (1996) Sand reinforced with shredded with waste tires. J Geotech Eng 122(9):760–767

Ghazavi M, Sakhi MA (2009) Influence of optimized tire shreds on shear strength parameters of sand. Int J Geomechan, ASCE 5:58–65

Gray DH, Ohashi H (1983) Mechanics of fiber reinforcement in sand. J Geotech Div, ASCE 109(3):335–353

Gray DH, Al-Refeai T (1986) Behavior of fabric-vs. fiber reinforced sand. J Geotech Div, ASCE 112(8):804–820

Hatef N, Rahimi MM (2006) Experimental investigation of bearing capacity of sand reinforced with randomly distributed tire shreds. Const Build Mater 20:910–916 Elsevier

Humphrey DN, Sandford TC, Cribbs MM, Manion WP (1993) Shear strength and compressibility of tire chips for use as retaining wall backfill. Transp Res Rec 1422

Humphrey, D.N., Katz, L.E. and Blumenthal, M. (1994) Water quality effects of tire chip fill placed above the groundwater table. ASTM STP 1275, M. A. Wasemiller and K. B. Hoddinott, eds., Philadelphia, 299-313

Ladd RS (1978) Preparing test specimens using under compaction. Geotech Test J 1(1):16–23

Masad E, Taha R, Ho C, Papaginanakis T (1996) Engineering properties of tire/soil mixture as a lightweight material. Geotech Test J 19(3):294–304

Molenaar D, Bosscher JS, Ten Brink B, Driessen AJ, Konings WN (1993) Generation of a proton motive force by histidine decarboxylation and electrogenic histidine/histamine antiport in Lactobacillus buchneri. J Bacteriol 175(10):2864–2870

Moo-Young H, Sellasie K, Zeroka D, Sabnis G (2003) Physical and chemical properties of recycled tire shreds for use in construction. J Environ Eng 129(10):921–929

Neaz Sheikh, M. Mashiri, M S. Vinod, J S. and Hing-Ho Tsang, M. (2012) Shear and compressibility Behaviour of sand-tyre crumb mixtures. J Mater Civil Eng, ASCE

OʾShaughnessy V, Garga VK (2000b) Tire reinforced earthfill. Part 3: Enviromental assessment. Can Geotech J 37:117–131

Rao N, Dutta RK (2006) Compressibility and strength behaviour of sand-tyre chip mixtures. Geotech Geol Eng 24(3):711–724

Tafreshi SM, Khalaj O, Dawson AR (2014) Repeated loading of soil containing granulated rubber and multiple geocell layers. Geotext Geomembr 42(1):25–38

Tafreshi SM, Mehrjardi GT, Dawson AR (2012) Buried pipes in rubber-soil backfilled trenches under cyclic loading. J Geotech Geoenviron 138(11):1346–1356

Tavakoli Mehrjardi G, Moghaddas Tafreshi SN, Dawson AR (2015) Numerical analysis on buried pipes protected by combination of geocell reinforcement and rubber-soil mixture. Int J Civil Eng 13(2):90–104

Trautmann CH, Kulhawy FH (1994) Uplift load-displacement behavior of spread oundations. J Geotech Eng ASCE 114(2):168–183

Zornberg JG, Viratjandr C, Cabral AR (2004) Behaviour of tire shred-sand mixtures. Can Geotech J 41(2):227–241

Youwai S, Bergado DT (2003) Strength and deformation characteristics of shredded rubber tire-sand mixtures. Can Geotech J 40(2):254–264

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Anvari, S.M., Shooshpasha, I. Influence of size of granulated rubber on bearing capacity of fine-grained sand. Arab J Geosci 9, 707 (2016). https://doi.org/10.1007/s12517-016-2744-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-016-2744-8