Abstract

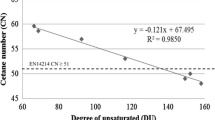

Biodiesels are alkyl esters produced by transesterification of higher fatty acids (aliphatic chains composed of 14 to 22 carbon units) from animal fats and/or vegetable oils. The cold filter plugging points (CFPP) of biodiesels are not only higher than that of petro-diesel, but they also differ from the melting point of the raw (unesterified) materials. In this study, we empirically derived equations that estimated the CFPP of a biodiesel based on its fatty acid content, using various biodiesel blends containing four methyl esters with different fatty acid compositions: soybean (SME), palm (PME), rapeseed (RME), and lard (LME). These blending ratio experiments yielded three equations that described the correlation between CFPP and fatty acid content: Y (CFPP, °C) = −3.1X (blending ratio) − 12.7 (PME/SME); Y = 2.2X − 10.7 (LME/SME); and Y = −4.0X − 13.0 (PME/RME). We also obtained the correlation between CFPP and total saturated fatty acid methyl ester content in the biodiesels: Y (CFPP, °C) = 0.449X (total saturated fatty acid methyl ester content, wt%) − 9.198. These empirical equations accurately predicted CFPP values of biodiesel compounds with known fatty acid compositions, facilitating the use of diverse biodiesels in industrial fields.

Similar content being viewed by others

References

Mittelbach, M. and C. Remschmidt (2004) Biodiesel — The Comprehensive Handbook. 1st ed., Boersedruck Ges.m.b.H, Vienna, Austria.

Jeong, G. T. and D. H. Park (2006) Batch (one-and two-stage) production of biodiesel fuel from rapeseed oil. Appl. Biochem. Biotechnol. 129–132: 668–679.

Jeong, G. T., D. H. Kim, and D. H. Park (2007) Response surface methodological approach for optimization of free fatty acid removal in feedstock. Appl. Biochem. Biotechnol. 136–140: 583–593.

Lang, X., A. K. Dalai, N. N. Bakhshi, M. J. Reaney, and P. B. Hertz (2001) Preparation and characterization of bio-diesels from various bio-oils. Bioresour. Technol. 80: 53–62.

Ma, F. and M. A. Hanna (1999) Biodiesel production: a review. Bioresour. Technol. 70: 1–15.

Usta, N. (2005) Use of tobacco seed oil methyl ester in a turbocharged indirect injection diesel engine. Biomass Bioenergy 28: 77–86.

Kim, S. J., S. M. Jung, Y. C. Park, and K. Park (2007) Lipase catalyzed transesterification of soybean oil using ethyl acetate, an alternative acyl acceptor. Biotechnol. Bioprocess Eng. 12: 441–445.

Lee, D. H., J. M. Kim, H. Y. Shin, S. W. Kang, and S. W. Kim (2006) Biodiesel production using a mixture of immobilized Rhizopus oryzae and Candida rugosa lipases. Biotechnol. Bioprocess Eng. 11: 522–525.

Krawczyk, T. (1996) Biodiesel-alternative fuel makes inroads but hurdles remain. Inform 7: 801–829.

Dorado, M. P., E. Ballesteros, J. A. Almeida, C. Schellert, H. P. Lohrlein, and R. Krause (2002) An alkalicatalyzed transesterification process for high free fatty acid waste oils. Trans. ASAE 45: 525–529.

Jeong, G. T., H. S. Yang, S. H. Park, and D. H. Park (2007) Optimization of biodiesel production from rapeseed oil using response surface methodology. Kor. J. Biotechnol. Bioeng. 22: 222–227.

Park, J. Y., D. K. Kim, J. P. Lee, S. C. Park, Y. J. Kim, and J. S. Lee (2008) Blending effects of biodiesels on oxidation stability and low temperature flow properties. Bioresour. Technol. 99: 1196–1203.

Knothe, G. (2005) Dependence of biodiesel fuel properties on the structure of fatty acid alkyl esters. Fuel Process. Technol. 86: 1059–1070.

Korean Standard Association (2003) Animal and vegetable fats and oils analysis by gas chromatography of methyl esters of fatty acids. KS H ISO 5508.

Korean Standard Association (2003) Petroleum products and lubricant determination of acid or base number: colour indicator titration method. KS M ISO 6618.

Korean Standard Association (2002) Test methods for acid value, saponification value, ester value, hydroxyl value and unsaponifiable matter of chemical products. KS M 0065.

Kang, Y. M. and H. S. Kim (2001) Emulsified transesterification of soybean oil into biodiesel. J. Kor. Oil Chemists’ Soc. 18: 298–305.

Author information

Authors and Affiliations

Corresponding author

Additional information

The first two authors equally contributed to this work.

Rights and permissions

About this article

Cite this article

Jeong, GT., Park, JH., Park, SH. et al. Estimating and improving cold filter plugging points by blending biodiesels with different fatty acid contents. Biotechnol Bioproc E 13, 505–510 (2008). https://doi.org/10.1007/s12257-008-0144-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12257-008-0144-y