Abstract

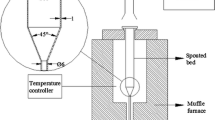

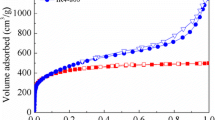

In this study, activated carbon was prepared from windmill palm sheath fiber (WPF) powder by KOH activation for full utilization of the bioresource. First, the optimal parameters of the activation technology, such as impregnation ratio, temperature, and time, were determined. The pyrolysis process and activation mechanism of KOH were investigated by thermogravimetric analysis (TGA). WPF powder-based activated carbons were then prepared under the optimized condition and characterized by SEM, FTIR, XRD, and nitrogen adsorption techniques. The reaction mechanisms were deduced in two phases. The reaction mechanisms in the first carbonization process were mainly related to substitution, scission, and oxidization reactions of methylene. In the second activation process, KOH and carbon began to react at 350 °C, producing potassium compounds, which further reacted with carbon. Results show that the optimal process for preparing an excellent adsorbent from WPF employs an impregnation ratio of 4:1 at 850 °C for 2.5 h, which can result in a good adsorption property for methylene blue, high BET surface area of 1734.34 m2/g, and total pore volume of 0.96 cm3/g. WPF-based activated carbon demonstrates a remarkable adsorption capacity, and thus WPF has great potential value as a new agricultural resource.

Similar content being viewed by others

References

Z. H. Liu, J. R. Qiu, Z. Q. Tan, H. C. Zeng, H. Liu, X. Hu, and M. N. Zhang, Proce. CSEE, 32, 64 (2012).

I. A. W. Tan, A. L. Ahmad, and B. H. Hameed, J. Hazard. Mater., 164, 473 (2009).

A. Arami-Niya, W. M. A. W. Daud, and F. S. Mjalli, J. Anal. Appl. Pyrol., 89, 197 (2010).

D. B. Wang, Z. Geng, B. Li, and C. M. Zhang, Electrochimi. Acta, 173, 377 (2015).

A. Kumar and H. M. Jena, Appl. Surf. Sci., 356, 753 (2015).

P. Rechnia, A. Malaika, and M. Kozlowski, Fuel, 154, 338 (2015).

M. E. Fernandez, G. V. Nunell, P. R. Bonelli, and A. L. Cukierman, Ind. Crop. Prod., 62, 437 (2014).

A. S. Ello, L. K. C. de Souza, A. Trokourey, and M. Jaroniec, J. CO 2 Util., 2, 35 (2013).

W. Chen, X. Liu, R. L. He, T. Lin, Q. F. Zeng, and X. G. Wang, Powder Technol., 234, 76 (2013).

M. A. Lillo-Ródenas, J. Juan-Juan, D. Cazorla-Amorós, and A. Linares-Solano, Carbon, 42, 1371 (2004).

I. Ozdemir, M. Sahin, R. Orhan, and M. Erdem, Fuel Process. Technol., 125, 200 (2014).

H. Treviño-Cordero, L. G. Juárez-Aguilar, D. I. Mendoza-Castillo, V. Hernández-Montoya, A. Bonilla-Petriciolet, and M. A. Montes-Morán, Ind. Crop. Prod., 42, 315 (2013).

M. C. Ncibi, B. Mahjoub, and M. Seffen, J. Hazard. Mater., 139, 280 (2007).

W. Maatar, S. Alila, and S. Boufi, Ind. Crop. Prod., 49, 33 (2013).

Y. S. Ho, W. T. Chiu, and C. C. Wang, Bioresour. Technol., 96, 1285 (2005).

I. A. W. Tan, B. H. Hameed, and A. L. Ahmad, Chem. Eng. J., 127, 111 (2007).

S. Senthilkumaar, P. R. Varadarajan, K. Porkodi, and C. V. Subbhuraam, J. Colloid Interface Sci., 284, 78 (2005).

A. Macías-García, E. M. Cuerda-Correa, M. Olivares-Marín, A. Díaz-Paralejo, and M. Á. Díaz-Díez, Ind. Crop. Prod., 35, 105 (2012).

S. Sivakumar, P. Senthilkumar, and V. Subburam, Bioresour. Technol., 80, 233 (2001).

K. S. K. Reddy, A. Al Shoaibi, and C. Srinivasakannan, New Carbon Mater., 27, 344 (2012).

M. Guo, T. H. Zhang, B. W. Chen, and L. Cheng, Compos. Pt. A-Appl. Sci. Manuf., 62, 45 (2014).

L. Cheng, T. H. Zhang, M. Guo, and X. L. Li, Wood Fiber Sci., 46, 270 (2014).

Y. X. Huang, E. Ma, and G. J. Zhao, Ind. Crop. Prod., 69, 447 (2015).

J. Yang, Z. Shen, and Z. Hao, Carbon, 42, 1872 (2004).

Y. Chen, L. J. Zhou, Y. Z. Hong, F. Cao, L. Li, and J. B. Li, New Carbon Mater., 25, 151 (2010).

J. J. Kong, Q. Y. Yue, P. Zhao, B. Y. Gao, Q. Li, Y. Wang, H. H. Ngo, and W. S. Guo, Fuel Process. Technol., 140, 67 (2015).

Y. J. Kan, Q. Y. Yue, B. Y. Gao, and Q. Li, Mater. Lett., 159, 443 (2015).

B. Cagnon, X. Py, A. Guillot, F. Stoeckli, and G. Chambat, Bioresour. Technol., 100, 292 (2009).

D. Lozano-Castelló, J. M. Calo, D. Cazorla-Amorós, and A. Linares-Solano, Carbon, 45, 2529 (2007).

M. A. Lillo-Roódenas, D. Cazorla-Amorós, and A. Linares-Solano, Carbon, 41, 267 (2003).

F. C. Wu, R. L. Tseng, and R. S. Juang, J. Colloid Interface Sci., 283, 49 (2005).

L. Zhu, H. Qi, M. Lv, Y. Kong, Y. Yu, and X. Xu, Biores. Technol., 124, 455 (2012).

K. Kirtania, J. Tanner, K. B. Kabir, S. Rajendran, and S. Bhattacharya, Bioresour. Technol., 151, 36 (2014).

P. Sathya, G. Velraj, and S. Meyvel, Adv. Appl. Sci. Res., 3, 776 (2012).

E. C. Lima, B. Royer, J. C. P. Vaghetti, N. M. Simon, B. Cunha, F. A. Pavan, E. V. Benvenuti, R. Veses, and C. Airold, J. Hazard. Mater., 155, 536 (2008).

J. C. Domínguez, M. Oliet, M. V. Alonso, E. Rojo, and F. Rodríguez, Ind. Crops Prod., 42, 308 (2013).

K. Y. Foo and B. H. Hameed, Desalination, 275, 302 (2011).

S. Brunauer, P. H. Emmet, and F. Teller, J. Am. Chem. Soc., 60, 309 (1938).

S. Yorgun, N. Vural, and H. Demiral, Mater., 122, 189 (2009).

A. C. Lua and J. Guo, Colloid Surf. A-Physicochem. Eng. Asp., 179, 151 (2001).

X. Ma, F. Zhang, and J. Zhu, Bioresour. Technol., 164, 1 (2014).

A. Ahmadpour and D. D. Do, Carbon, 34, 471 (1996).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, J., Li, K., Zhang, T. et al. Development of Activated carbon from Windmill palm sheath fiber by KOH activation. Fibers Polym 17, 880–887 (2016). https://doi.org/10.1007/s12221-016-6328-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-016-6328-8