Abstract

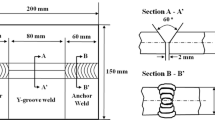

The effects of the microstructural constituents, chemical composition, and retained austenite on high-strength weld metal were studied using preheat-free steels and GMAW solid wires with a low hydrogen content. The cold cracking susceptibility of these GMAW wires was evaluated using the y-groove Tekken test. The results showed that acicular ferrite produced the greatest resistance to cold cracking and that the microstructure of the deposit was more important than the hardness and diffusible hydrogen content in low-hydrogen weld metal. Crack blunting and branching occurred when a crack propagated through fine acicular ferrite because of the fine interlocking nature of the microstructure. Alloying elements for nucleating acicular ferrite, such as Ti, Al, and V, are required for proper austenite grain size, and sequence of inclusion formation was identified in the present paper. Furthermore, the retained austenite was not found to play the role of a hydrogen trapping site and so had no effect on the cold cracking susceptibility at a low preheating temperature (≤100°C) and low heat input (≤1.5 KJ/mm) to the weld metal.

Similar content being viewed by others

References

S. Kou, Welding metallurgy, John Wiley and Sons, New York, 1987.

N. Yurioka, ISIJ Int., 6 (2001) 566–570.

N. Yurioka, T. Kasuya, Weld in the World, 5 (1995) 31–38.

T. Kitada, K. Fukuda, Nippon Kokan Technical Report, Overseas, 47 (1986).

J. W. Fisher, R. J. Dexter, Weld J., 35 (1994).

J. H. Kim, J. S. Seo, H. J. Kim, H. S. Ryoo, K. H. Kim and M. Y. Huh, Metals Mater. Int., 14 (2008) 239–245.

J. M. Dowling, J. M. Corbett and H. W. Kerr, Metall. Trans. A, 17A (1986) 1611–1623.

I. Madariaga, J. L. Romeo and I. Gutierrez, Metall. Mater. Trans. A, 29A (1998) 1003–1015.

F. Ishikawa, T. Takahashi and T. Ochi, Metall. Mater. Trans. A, 25A (1994) 929–936.

C. B. Dallam and D. L. Olson, Weld. J., (1989) 198s–205s.

Y. D. Park, I. S. Maroef, A. Landau and D. L. Olsen, Weld. J., (2002) 27s–35s.

C. R. Wildash, C. Cochrane, R. Gee and D. J. Widgery, Trends in weld. Res., Int. Conf., 745–750.

AWS A 4.3, American Welding Society, (1993).

AWTM A 370, ASTM International, (2010).

AWS D 1.1, American Welding Society, (2001).

D. J. Abson and E. R. Dolby, IIW Doc. IXJ-29-80 (Dolby) (1980).

D. Uwer and H. Hohne, IIW Doc. IX-1631-91 (1991) 282–286.

J. M. Gregg and H. K. D. H. Bhadeshia, Metall. Mater. Trans. A, 25A (1994) 1603–1611.

A. O. Kluken and O. Grong, Metall. Trans. A, 20A (1989) 1335–1349.

Y. I. Matrosov and V. N. Anashenko, Metal Sci. And Heat Treat., 10 (1971) 78–80.

P. H. M. Hart, Weld. J. (1986) 14s–22s.

H. J. Kim and B. Y. Kang, ISIJ Int., 5 (2003) 706–713.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper was recommended for publication in revised form by Associate Editor Vikas Tomar

Hui-Jun Yi received his M.S. degree from Graduate School of Pusan National University, Korea. He is currently in the doctoral course of Graduate School of Pusan National University, Korea. Mr. Yi’s research interests include weldability of ferrous and nonferrous metals and CAE for predicting welding residual stress and distortion.

Yong-Jun Lee received his M.S. degree from Graduate School of Pusan National University, Korea. He is currently in the doctoral course of the Graduate School of Pusan National University, Korea. Mr. Lee’s research interests include laser welding and CAE for predicting fatigue life.

Jong-Yun Kim received his B.S. in Mechanical Engineering from Pusan National University, Korea. He is currently in the master’s course of the Graduate School of Pusan National University, Korea. Mr. Kim’s research interests include friction stir welding and fatigue life of stainless steel weldment.

Sung-Su Kang received his M.S. and Ph.D. degrees from Graduate School of Seoul National University, Korea. He is currently a Professor at the School of Mechanical University at Pusan National University in Pusan, Korea. Dr. Kang’s research interests include plastic working process and CAE for plastic working.

Rights and permissions

About this article

Cite this article

Yi, HJ., Lee, YJ., Kim, JY. et al. Effect of microstructure and chemical composition on cold crack susceptibility of high-strength weld metal. J Mech Sci Technol 25, 2185–2193 (2011). https://doi.org/10.1007/s12206-011-0529-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-011-0529-2