Abstract

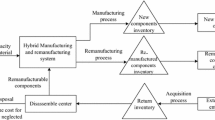

This paper addresses the optimization of make-to-order hybrid manufacturing - remanufacturing system to make capacity and inventory decisions jointly along with production decisions. The proposed system considers a common production facility and the same assembly/disassembly line to perform manufacturing and remanufacturing operations simultaneously. The current study takes into account an environment where new and remanufactured (reman) products competing to each other that is, the common demand stream for both products but different selling prices. Furthermore, the relative capacity consumed by remanufacturing over the manufacturing is explained in two ways, namely less capacity intensive case and more capacity intensive case. Differently, from previous studies, we consider a scenario with a discounted selling price for reman products, shortage penalty costs, lost sales, disposal and uncertainty in demand, amount and yield of returns. Hence, to handle those uncertainties, a scenario-based stochastic programming model in a two-stage setting is presented. In the first stage, the raw material inventory and production capacity levels are planned and in the second stage, the production, inventory and disposal decisions are determined by balancing overage and underage costs. The results indicate that net values associated with new and reman products can be decisive in choosing either manufacturing or remanufacturing.

Similar content being viewed by others

Abbreviations

- M:

-

Number of scenarios

- α :

-

Relative capacity required for remanufacturing over manufacturing

- γ:

-

Relative capacity required for manufacturing over remanufacturing

- C Z :

-

Unit capacity investment cost ($)

- C h :

-

Unit inventory holding cost ($)

- C w :

-

Unit disposal cost ($)

- C an :

-

Unit raw materials purchasing cost per unit ($)

- C ar :

-

Unit returns acquiring cost per unit ($)

- C n :

-

Unit processing cost of new product ($)

- C r :

-

Unit processing cost of reman product ($)

- C sp :

-

Shortage penalty cost for new product per unit ($)

- ν n :

-

Net value associated with the new product ($)

- ν r :

-

Net value associated with reman product ($)

- p n :

-

Unit selling price of new product ($)

- p r :

-

Unit selling price of reman product ($)

- p m :

-

Probability associated with each scenario

- d :

-

Product demand (units)

- Q r :

-

Core returns inventory level (units)

- y r :

-

Yield of core returns

- Q n :

-

Raw material inventory level (units)

- Z :

-

Production capacity level (units)

- q n :

-

Optimal manufacturing quantity (units)

- q r :

-

Optimal remanufacturing quantity (units

References

Tsao Y C., Linh V T., Lu J C and Yu V. 2018 A supply chain network with product remanufacturing and carbon emission considerations: a two-phase design. J. Intell. Manuf. 29: 693–705

Kumar A, Chinnam R B and Murat A 2017 Hazard rate models for core return modeling in auto parts remanufacturing. Int. J. Prod. Econ. 183: 354–361

Reddy K N, Kumar A, Sarkis J and Tiwari M K 2019 Effect of carbon tax on reverse logistics network design. Comput. Ind. Eng., 139:106184

Lu Q, Goh M, Garg M and De Souza R 2014 Remanufacturing in Asia: location choice and outsourcing. Int. J. Logist. Manag. 25:20–34

Subramoniam R, Huisingh D, Chinnam R B and Subramoniam S 2013 Remanufacturing decision-making framework (RDMF): research validation using the analytical hierarchical process. J. Clean. Prod. 40:212–220

Reddy K N, Kumar A and Ballantyne E E F 2019 A three-phase heuristic approach for reverse logistics network design incorporating carbon footprint. Int. J. Prod. Res. 57(19):6090–6114

Choudhary N and Singh N K N K 2011 Remanufacturing in India: approaches, potentials & technical challenges. Int. J. Ind. Eng. Technol. 3(3): 223–227

yan Wang Y and yuan Zhang Y 2017 Remanufacturer’s production strategy with capital constraint and differentiated demand. J. Intell. Manuf., 28(4): 869–882

Guide V D R Jr., Teunter R H and Van Wassenhove L N 2003 Matching demand and supply to maximize profits from remanufacturing. Manuf. Serv. Oper. Manag. 5(4):303–316

Pokharel S and Mutha A 2009 Perspectives in reverse logistics: a review. Resour. Conserv. Recycl. 53:175–182

Van Der Laan E, Salomon M, Dekker R and Van Wassenhove L 1999 Inventory control in hybrid systems with remanufacturing. Manage. Sci. 45(5): 733–747

Takahashi K, Doi Y, Hirotani D and Morikawa K 2014 An adaptive pull strategy for remanufacturing systems. J. Intell. Manuf. 25(4): 629–645

Benjaafar S and ElHafsi M 2006 Production and inventory control of a single product assemble-to-order system with multiple customer classes. Manage. Sci. 52(12): 1896–1912

Zhang F, Guan Z, Zhang L, Cui Y, Yi P and Ullah S 2019 Inventory management for a remanufacture-to-order production with multi-components (parts). J. Intell. Manuf. 30(1): 59–78

Gong X and Chao X 2013 Optimal control policy for capacitated inventory systems with remanufacturing. Oper. Res. 61(3): 603–611

Bulmuş S C, Zhu S X and Teunter R 2013 Capacity and production decisions under a remanufacturing strategy. Int. J. Prod. Econ. 145(1): 359–370

Van Mieghem J A 2003 Capacity management, investment, and hedging: review and recent developments. Manuf. Serv. Oper. Manag. 5(4): 269–302

Van Mieghem J A and Rudi N 2002 Newsvendor networks: inventory management and capacity investment with discretionary activities. Manuf. Serv. Oper. Manag. 4(4): 313–335

Birge J R and Louveaux F 2011 Introduction to Stochastic Programming. Springer Science+Business Media, New York

El-Sayed M, Afia N and El-Kharbotly A 2010 A stochastic model for forward-reverse logistics network design under risk. Comput. Ind. Eng. 58(3): 423–431

Reddy K N and Kumar A Capacity investment and inventory planning for a hybrid manufacturing–remanufacturing system in the circular economy. Int. J. Prod. Res.,7543

Macedo P B, Alem D, Santos M, Junior M L and Moreno A 2016 Hybrid manufacturing and remanufacturing lot-sizing problem with stochastic demand, return, and setup costs. Int. J. Adv. Manuf. Technol. 82: 1241–1257

Soleimani H, Seyyed-Esfahani M and Shirazi M A 2016 A new multi-criteria scenario-based solution approach for stochastic forward/reverse supply chain network design. Ann. Oper. Res. 242: 399–421

Kaut M and Wallace S W 2003 Evaluation of scenario-generation methods for stochastic programming. Pacific J. Optim. 3(2): 257–271

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Reddy, K.N., Kumar, A. & Velaga, N.R. Scenario-based two-stage stochastic programming for a Hybrid Manufacturing-Remanufacturing System with the uncertainty of returns, quality and demand. Sādhanā 46, 59 (2021). https://doi.org/10.1007/s12046-021-01579-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-021-01579-3