Abstract

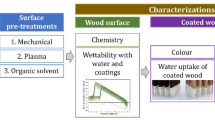

Thermally modified wood (TMW) is increasingly used in exterior applications as an alternative to tropical hardwoods or wood impregnated with biocides. Despite its enhanced biological durability and dimensional stability, a surface treatment of TMW with coating systems can be required in certain applications. This study assessed material characteristics of Norway spruce and Scots pine wood that was thermally modified according to the ThermoWood® process and their effect on the performance of commercially available coating systems: a solventborne oil, a waterborne alkyd-reinforced acrylate paint and a waterborne acrylate paint. Residual extractives and remaining degradation products found in TMW, carry the risk of causing discoloration or of interfering with the curing reactions of coating systems. The penetration of coating systems into TMW was not found to differ from unmodified wood, although an excessive penetration of solventborne oil was found occasionally for TMW. The adhesion strength of waterborne coatings depended on the system that was used. While one system performed sufficiently on TMW, the other coating systems showed a considerable reduction in adhesion strength already after a mild treatment (<200°C). This reduction could not be attributed to the increase in hydrophobicity of TMW that was evident from contact angle measurements, but was rather related to the mechanical interaction of the specific substrate/coating system.

Similar content being viewed by others

References

Militz, H, Altgen, M, “Processes and properties of thermally modified wood manufactured in Europe.” In: Schultz, TP, Goodell, B, Nicholas DD (eds.) Deterioration and protection of sustainable biomaterials, ACS Symposium Series, vol 1158, pp 269–285, American Chemical Society, Washington, DC, 2014

Mayes, D, Oksanen, O, ThermoWood Handbook. Finnish ThermoWood Association, Helsinki (2003)

Popper, R, Niemz, P, Eberle, G, “Investigations on the Sorption and Swelling Properties of Thermally Treated Wood.” Holz Roh Werkst., 63 (2) 135–148 (2005)

Kamdem, DP, Pizzi, A, Jermannaud, A, “Durability of Heat-Treated Wood.” Eur. J. Wood Wood Prod., 60 (1) 1–6 (2002)

Boonstra, MJ, Van Acker, J, Tjeerdsma, BF, Kegel, EV, “Strength Properties of Thermally Modified Softwoods and its Relation to Polymeric Structural Wood Constituents.” Ann. For. Sci., 64 (7) 679–690 (2007)

Tjeerdsma, BF, Boonstra, M, Pizzi, A, Tekely, P, Militz, H, “Characterisation of Thermally Modified Wood: Molecular Reasons for Wood Performance Improvement.” Holz Roh Werkst., 56 (3) 149–153 (1998)

Tjeerdsma, BF, Militz, H, “Chemical Changes in Hydrothermal Treated Wood: FTIR Analysis of Combined Hydrothermal and Dry Heat-Treated Wood.” Holz Roh Werkst., 63 (2) 102–111 (2005)

Bourgois, J, Guyonnet, R, “Characterization and Analysis of Torrefied Wood.” Wood Sci. Technol., 22 (2) 143–155 (1988)

Wienhaus, O, “Modifizierung des Holzes durch eine milde Pyrolyse: abgeleitet aus den allgemeinen Prinzipien der Thermolyse des Holzes.” Wissenschaftliche Zeitschrift der Technischen Universität Dresden, 48 (2) 17–22 (1999)

Sivonen, H, Maunu, SL, Sundholm, F, Jämsa, S, Viitaniemi, P, “Magnetic Resonance Studies of Thermally Modified Wood.” Holzforschung, 56 (6) 648–654 (2002)

Jämsä, S, Ahola, P, Viitaniemi, P, “Long-term Natural Weathering of Coated ThermoWood.” Pigment Resin Technol., 29 (2) 68–74 (2000)

Huang, XA, Kocaefe, D, Kocaefe, Y, Boluk, Y, Pichette, A, “A Spectrocolorimetric and Chemical Study on Color Modification of Heat-Treated Wood During Artificial Weathering.” Appl. Surf. Sci., 258 (14) 5360–5369 (2012)

Feist, WC, Sell, J, “Weathering Behavior of Dimensionally Stabilized Wood Treated by Heating Under Pressure of Nitrogen Gas.” Wood Fiber Sci., 19 (2) 183–195 (1987)

Altgen, M, Adamopoulos, S, Militz, H, “Wood Defects During Industrial-Scale Production of Thermally-Modified Norway Spruce and Scots Pine.” Wood Mater. Sci. Eng., (2015). doi:10.1080/17480272.2014.988750

Podgorski, L, Roux, M, “Wood Modification to Improve the Durability of Coatings.” JOCCA Surf. Coat. Int., 82 (12) 590–596 (1999)

Poncsak, S, Kocaefe, D, Simard, F, Pichette, A, “Evolution of Extractive Composition During Thermal Treatment of Jack Pine.” J. Wood Chem. Technol., 29 (3) 251–264 (2009)

Nussbaum, RM, “The Effect of Processing and Treatment Parameters on the Discoloration of Painted Joinery Due to Resin Exudation from Knots.” Surf. Coat. Int. Part B Coat. Trans., 87 (3) 181–186 (2004)

Grüll, G, Podgorski, L, Truskaller, M, Spitaler, I, Georges, V, Bollmus, S, Steitz, A, “Performance of Selected Types of Coated and Uncoated Modified Wood in Artificial and Natural Weathering.” In: The International Research Group on Wood Protection, Doc. No IRG/WP 10-40510, Biarritz, Fance, May 2010

Kesik, HI, Akyildiz, MH, “Effect of Heat Treatment on the Adhesion Strength of Water Based Wood Varnishes.” Wood Res., 60 (6) 987–994 (2015)

de Moura, LF, Brito, JO, Nolasco, AM, Uliana, LR, De Muniz, GIB, “Evaluation of Coating Performance and Color Stability on Thermally Rectified Eucalyptus Gradis and Pinus Caribaea var Hondurensis Woods.” Wood Res., 58 (2) 231–242 (2013)

Allen, KW, “A Review of Contemporary Views of Theories of Adhesion.” J. Adhes., 21 (3–4) 261–277 (1987)

Pizzi, A, “A Brief, Non-Mathematical Review of Adhesion Theories as Regards Their Applicability to Wood.” Holzforschung und Holzverwertung, 44 (1) 6–11 (1992)

Kollmann, F, Schneider, A, “Über das Sorptionsverhalten wärmebehandelter Hölzer.” Eur. J. Wood Wood Prod., 21 (3) 77–85 (1963)

Metsa-Kortelainen, S, Antikainen, T, Viitaniemi, P, “The Water Absorption of Sapwood and Heartwood of Scots Pine and Norway Spruce Heat-Treated at 170°C, 190°C, 210°C and 230°C.” Holz Roh Werkst., 64 (3) 192–197 (2006)

Gérardin, P, Petrič, M, Pétrissans, M, Lambert, J, Ehrhrardt, JJ, “Evolution of Wood Surface Free Energy After Heat Treatment.” Polym. Degrad. Stab., 92 (4) 653–657 (2007)

Petrič, M, Knehtl, B, Krause, A, Militz, H, Pavlic, M, Petrissans, M, Rapp, A, Tomazic, M, Welzbacher, C, Gerardin, P, “Wettability of Waterborne Coatings on Chemically and Thermally Modified Pine Wood.” J. Coat. Technol. Res., 4 (2) 203–206 (2007)

Metsä-Kortelainen, S, Viitanen, H, “Wettability of Sapwood and Heartwood of Thermally Modified Norway Spruce and Scots Pine.” Eur. J. Wood Wood Prod., 70 (1) 135–139 (2012)

Sundqvist, B, Karlsson, O, Westermark, U, “Determination of Formic-Acid and Acetic Acid Concentrations Formed During Hydrothermal Treatment of Birch Wood and its Relation to Colour, Strength and Hardness.” Wood Sci. Technol., 40 (7) 549–561 (2006)

Hofmann, T, Wetzig, M, Rétfalvi, T, Sieverts, T, Bergemann, H, Niemz, P, “Heat-Treatment with the Vacuum-Press Dewatering Method: Chemical Properties of the Manufactured Wood and the Condensation Water.” Eur. J. Wood Wood Prod., 71 (1) 121–127 (2013)

Boonstra, M, Rijsdijk, JF, Sander, C, Kegel, E, Tjeerdsma, B, Militz, H, Van Acker, J, Stevens, M, “Microstructural and Physical Aspects of Heat Treated Wood. Part 1: Softwoods.” Maderas Ciencia i tecnología, 8 (3) 193–208 (2006)

Awoyemi, L, Jones, IP, “Anatomical Explanations for the Changes in Properties of Western Red Cedar (Thuja plicata) Wood During Heat Treatment.” Wood Sci. Technol., 45 (2) 261–267 (2011)

Nussbaum, RM, “Natural Surface Inactivation of Scots Pine and Norway Spruce Evaluated by Contact Angle Measurements.” Holz Roh Werkst., 57 (6) 419–424 (1999)

EN ISO 24624, “Paint and varnishes: Pull-off test.” International Organization for Standardization, 2003

EN ISO 2409, “Paint and varnishes: Cross-cut test.” International Organization for Standardization, 1994

Karlsson, O, Torniainen, P, Dagbro, O, Granlund, K, Moren, T, “Presence of Water-Soluble Compounds in Thermally Modified Wood: Carbohydrates and Furfurals.” BioResources, 7 (3) 3679–3689 (2012)

Manninen, A-M, Pasanen, P, Holopainen, JK, “Comparing the VOC Emissions Between Air-Dried and Heat-Treated Scots Pine Wood.” Atmos. Environ., 36 (11) 1763–1768 (2002)

Altgen, M, Ala-Viikari, J, Hukka, A, Tetri, T, Militz, H, “Impact of elevated steam pressure during the thermal modification of Scots pine and Norway spruce.” In: COST Action FP0904 workshop, Skelleftea, Sweden, May 2014

Wellons, JD, Krahmer, RL, Raymond, R, Sleet, G, “Durability of Exterior Siding Plywood with Southeast Asian Hardwood Veneers.” For. Prod. J., 27 (2) 38–44 (1977)

Hse, CY, Kuo, MI, “Influence of Extractives on Wood Gluing and Finishing: A Review.” For. Prod. J., 38 (1) 52–56 (1988)

Stefke, B, Dunky, M, “Catalytic Influence of Wood on the Hardening Behavior of Formaldehyde-Based Resin Adhesives Used for Wood-Based Panels.” J. Adhes. Sci. Technol., 20 (8) 761–785 (2006)

Sernek, M, Boonstra, M, Pizzi, A, Despres, A, Gérardin, P, “Bonding Performance of Heat Treated Wood with Structural Adhesives.” Holz Roh Werkst., 66 (3) 173–180 (2008)

Herrera, R, Muszyńska, M, Krystofiak, T, Labidi, J, “Comparative Evaluation of Different Thermally Modified Wood Samples Finishing with UV-Curable and Waterborne Coatings.” Appl. Surf. Sci., 357 (Part B) 1444–1453 (2015)

Hakkou, M, Pétrissans, M, El Bakali, I, Gérardin, P, Zoulalian, A, “Wettability Changes and Mass Loss During Heat Treatment of Wood.” Holzforschung, 59 (1) 35–37 (2005)

Nguyen, T, Johns, WE, “The Effects of Aging and Extraction on the Surface Free Energy of Douglas Fir and Redwood.” Wood Sci. Technol., 13 (1) 29–40 (1979)

Gardner, DJ, Generalla, NC, Gunnells, DW, Wolcott, MP, “Dynamic Wettability of Wood.” Langmuir, 7 (11) 2498–2502 (1991)

Wålinder, MEP, “Study of Lewis Acid-Base Properties of Wood by Contact Angle Analysis.” Holzforschung, 56 (4) 363–371 (2002)

Gindl, M, Reiterer, A, Sinn, G, Stanzl-Tschegg, SE, “Effects of Surface Ageing on Wettability, Surface Chemistry, and Adhesion of Wood.” Holz Roh Werkst., 62 (4) 273–280 (2004)

Inari, GN, Pétrissans, M, Lambert, J, Ehrhardt, JJ, Gérardin, P, “XPS Characterization of Wood Chemical Composition After Heat-Treatment.” Surf. Interface Anal., 38 (10) 1336–1342 (2006)

Nussbaum, RM, “Penetration of Water-Borne Alkyd Emulsions and Solvent-Borne Alkyds into Wood: Autoradiographic and SEM-EDXA Studies.” Holz Roh Werkst., 52 (6) 389–393 (1994)

de Meijer, M, Thurich, K, Militz, H, “Comparative Study on Penetration Characteristics of Modern Wood Coatings.” Wood Sci. Technol., 32 (5) 347–365 (1998)

Stehr, M, Johansson, I, “Weak Boundary Layers on Wood Surfaces.” J. Adhes. Sci. Technol., 14 (10) 1211–1224 (2000)

Bull, SJ, Berasetegui, EG, “An Overview of the Potential of Quantitative Coating Adhesion Measurement by Scratch Testing.” In: Sinha, SK (ed.) Scratching of Materials and Applications. Tribology and Interface Engineering Series, No. 51, Elsevier B.V., Amsterdam, 2006

Evans, AG, Drory, MD, Hu, MS, “The Cracking and Decohesion of Thin Films.” J. Mater. Res., 3 (5) 1043–1049 (1988)

Phuong, LX, Shida, S, Saito, Y, “Effects of Heat Treatment on Brittleness of Styrax Tonkinensis Wood.” J. Wood Sci., 53 (3) 181–186 (2007)

Acknowledgments

The authors thank the International ThermoWood Association (Helsinki, Finland) for their financial support, the provision of test material and fruitful discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Altgen, M., Militz, H. Thermally modified Scots pine and Norway spruce wood as substrate for coating systems. J Coat Technol Res 14, 531–541 (2017). https://doi.org/10.1007/s11998-016-9871-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-016-9871-8