Abstract

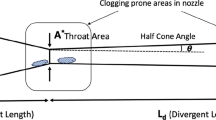

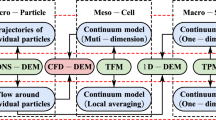

This work analyzes the mechanism of spray deposition by means of computational fluid dynamics (CFD) in order to reproduce virtually the spraying of a paint gun adopted for use in the automotive industry and to predict paint drop trajectories and film builds on the target surface. The prediction of the flow of the continuous phase was obtained by solving the time averaged Navier-Stokes equations in connection with suitable closure models for turbulence (RNG and Realizable k-ε). The dispersed phase was treated by a Lagrangian approach, by tracking numerically a large number of representative particles from the gun exit to the target surface. The initial conditions for the droplets were estimated from a detailed simulation of the paint jet at the exit of the nozzle. In this way one could evaluate positions and velocities of droplets at impact and estimate the properties of the deposited layer of paint. The method was validated by comparison with experimental data obtained by phase doppler anemometry and, subsequently, the approach was applied to different geometries and operating conditions.

Similar content being viewed by others

References

Kwok, K.C., “A Fundamental Study of Air Spray Painting,” Ph.D. Thesis, University of Minnesota, 1991.

Domnick, J., Lindenthal, A., Tropea, C., and Xu, T.-H., “Application of Phase-Doppler Anemometry in Paint Sprays,” Atomization and Sprays, 4, 437 (1994).

Morikita, H., and Taylor, A.M.K.P., “Application of Shadow Doppler Velocimetry to Paint Spray: Potential and Limitations in Sizing Optically Inhomogeneous Droplets,” Meas. Sci. Technol., 9, 221 (1998).

Carlton, G.N., and Flynn, M.R., “A Model to Estimate Worker Exposure to Paint Spray Mist,” Appl. Occup. Environ. Hyg., 12, 375 (1997).

Flynn, M.R., Gatano, B.L., McKernan, J.L., Dunn, K.H., Blazick, B.A., and Carlton, G.N., “Modeling Breathing Zone Concentrations of Airborne Contaminants Generated During Compressed Air Spray Painting,” Ann. Occup. Hyg., 43, 67 (1999).

Brouwer, D.H., Semple, S., Marquart, J., Cherrie, J.W., “A Dermal Model for Spray Painters. Part I: Subjective Exposure Modeling of Spray Paint Deposition,” Ann. Occup. Hyg. 45, 15 (2001).

Flynn, M.R., Sills, E.D., “On the Use of Computational Fluid Dynamics in the Prediction and Control of Exposure to Airbome Contaminants—An Illustration Using Spray Painting,” Ann. Occup. Hyg. 44, 191 (2000).

Rüger, M., Hohmann, S., Sommerfeld, M., and Kohnen, G., “Euler-Lagrange Calculation of Turbulent Sprays: The Effect of Droplet Collision and Coalescence,” Atomization and Sprays, 10, 47 (2000).

Hicks, P.G., and Senser, D.W., “Simulation of Paint Transfer in an Air Spray Process,” J. Fluids Eng., 117, 145 (1995).

Ye, Q., Domnick, J., and Khalifa, E., “Simulations of the Spray Coating Process Using a Pneumatic Atomizer,” Proc. ILASS-Europe 2002, Zaragoza, Spain, 2002.

Micheli, P., “Understanding How a Spray Gun Atomizes Paint,” Metal Finishing, 59 (October 2003).

Wilcox, D.C., Turbulence Modeling for CFD, DWC industries, La Canada, CA, 1993.

Launder, B.E., and Spalding, D.B., “The Numerical Computation of Turbulent Flows,” Comput. Meth. Appl. Mech. Eng., 3, 269 (1974).

Yakhot, V., and Orszag, S.A., “Renormalization Group Analysis of Turbulence,” J. Sci. Comput. 1, 3 (1986).

Shih, T.H., Liou, W.W., Shabbir, A., and Zhu, J., “A New k-ε Eddy-Viscosity Model for High Reynolds Number Turbulent Flows—Model Development and Validation,” Computers Fluids, 24, 227 (1995).

Crowe, C.T., Sommerfeld, M., and Tsuji, Y., Multiphase Flows with Droplets and Particles, CRC Press, Boca Raton, FL, 1997.

Hirt, C.W., and Nichols, B.D., “Volume of Fluid (VOF) Method for the Dynamics of Free Boundaries,” J. Comput. Phys., 39, 201 (1981).

Garbero, M., “Modeling of Spray Deposition Processes,” Ph.D. Thesis, Politecnico di Torino, Torino, Italy, 2004.

Mundo, C., Sommerfeld, M., and Tropea, C., “On the Modeling of Liquid Sprays Impinging on Surfaces,” Atomization and Sprays, 8, 625 (1998).

Cossali, G.E., Coghe, A., and Marengo, M., “The Impact of a Single Drop on a Wetted Solid Surface,” Exp. Fluids, 22, 463 (1997).

Balkan, T., and Arikan, M.A.S., “Modeling of Paint Flow Rate Flux for Circular Paint Sprays by Using Experimental Paint Thickness Distribution,” Mechanics Research Commun., 26, 609 (1999).

Kwok, K.C. and Liu, B.Y.H., “How Atomization Affects Transfer Efficiency,” Industrial Finishing, 28 (May 1992).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fogliati, M., Fontana, D., Garbero, M. et al. CFD simulation of paint deposition in an air spray process. J Coat. Technol. Res. 3, 117–125 (2006). https://doi.org/10.1007/s11998-006-0014-5

Issue Date:

DOI: https://doi.org/10.1007/s11998-006-0014-5