Abstract

The recovery of polyphenols from grape pomace (GP) supports the promotion of sustainable bioeconomy. Accordingly, the development of pre-treatment and extraction techniques using low-solvent amounts and energy-efficient processes is highly desirable. In this work, a comprehensive strategy to maximize phenol extraction from two Umbrian red wine cultivars, Cabernet Sauvignon and Merlot, was proposed. Focus was paid to sample pre- (fresh, air-, oven- and freeze-dried pomace) and post-extraction (chemical- and enzymatic-hydrolysis) treatments. An experimental design was applied to optimize phenol recovery by ultrasound-assisted extraction: the variables water content in ethanol (20–80% v/v) and time (10–30 min) highlighted a critical influence on the total phenol content (TPC) selected as the response. β-glucuronidase hydrolysis provided the highest TPC and in vitro total antioxidant capacity also improving phenol identification and quantification via HPLC–DAD (particularly evident for freeze-dried Merlot and Cabernet GP, which gave a total phenolic content measured by HPLC equal to 1904.08 mg/g and 2064.64 mg/g, respectively). LC-HRMS/MS analysis allowed identity confirmation of the major phenols, and cytotoxicity assay highlighted the safety of the selected β-glucuronidase extracts towards Caco2 cell line. Ultimately, in the present work, we have addressed the importance of the recovery of bioactive compounds from grape pomace by proposing a comprehensive analytical strategy in which different methodological alternatives have been evaluated to preserve these compounds, in a frame of sustainability on a larger industrial scale.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Wine grape (Vitis vinifera L.) processing covers an important part of the world’s agro-economic and industrial activities. Overall, global wine production in 2022 has been estimated at an average value of 260 million hectolitres (OIV, the International Organization of Vine and Win, 2022), with Italy, France, Spain and the USA being among the most important producers and leading exporter countries. During the winemaking process, approximately 20–25% of the total volume of vinified grapes ends up as pomace, which is mainly constituted of skin, seeds, pulp and other solid parts and represents the primary grape by-product. It is estimated that the worldwide production of grape pomace amounts to almost 8.49 million tons per year (Castellanos-Gallo et al., 2022). Large quantities of such waste are disposed of in landfills or by incineration with serious environmental deterioration and pollution (Sirohi et al., 2020). If on the one hand grape pomace represents a significant issue in terms of environmental impact and costs, on the other, it is a rich source of components with valuable biological activity and technological properties, such as fibre and phenolic compounds. The potential applications of such constituents in the food, pharmaceutical and cosmetic industries stem from their health-promoting effects associated with antioxidant, cardioprotective, neuroprotective properties and other benefits (Beres et al., 2017; Zhu et al., 2015). Phenolic compounds, which affect sensory quality and healthy properties of wines, are still largely present in the residual pomace resulting from the pressing and/or fermentation processes (Meinia et al., 2019). Such evidence justifies the interest of scientists and food industry in the search for new alternatives to exploit this by-product. In this context, in the last years, the scientific community is witnessing the spread of re-using agro-industrial by-products, including those deriving from the wine supply chain, to generate bio-products, biofuels or food ingredients with high-added value (Moro et al., 2021). The recovery of bioactive compounds is strictly associated with the application of sustainable extraction techniques, in line with the principles of green chemistry which promote fast and automated procedures with reduced solvent consumption (Armenta et al., 2019; Moro et al., 2021). Ultrasound-assisted extraction (UAE) (Caldas et al., 2018; Moro et al., 2021; Tao et al., 2014), microwave-assisted extraction (MAE) (Garrido et al., 2019; Moro et al., 2021), supercritical fluid extraction (SFE) (Da Porto & Natolino, 2017) and pulsed electric field (PEF) (Barba et al., 2015) have been largely exploited for the extraction of bioactives from grape pomace. However, the selection of the extraction method is not so obvious: it must be taken into consideration the possible degradation of target analytes and compositional changes (i.e. sensitivity to heat, light and oxygen, thermodegradation and hydrolysis reactions) which imply the need of selecting the most appropriate conditions to preserve the chemical integrity of bioactive compounds.

Furthermore, sample pre-treatment seems to have been mostly neglected in experimental designs. Also in this case, fast, economic and environmentally friendly techniques are crucial in the process valorisation as a whole (Ebrahimi et al., 2022).

The use of fresh grape pomace holds the advantage of avoiding artefacts due to sample degradation (Marchante et al., 2018; Pintać et al., 2018). Nevertheless, sample could be exposed to biochemical spoilage reactions, which can be minimized by drying processes. Air-drying is the most traditional and low-cost technique to lower the water content at low temperatures. Although this process prevents the degradation of the active constituents, the further progress of metabolic reactions due to the slow process kinetics could lead to a loss of quality. Alternatively, oven-drying allows the faster removal of moisture from fresh material, thereby reducing the drying time. While it is commonly recommended when time is an issue, the increase in temperature can adversely affect the recovery of heat-sensitive compounds. On the contrary, freeze-drying can ensure the preservation of thermolabile compounds in raw materials and improve the recovery of phenolic compounds due to the significant changes in the matrix microstructure that facilitate solvent penetration (González et al., 2020; Martìnez Garcìa et al., 2021; Saifullah et al., 2019; Souza da Costa et al., 2022).

Sokač and co-workers investigated the effects of different drying methods on the stability of polyphenol tannins and tartaric acid in grape pomace (Vitis vinifera) cv. Graševina (Sokač et al., 2022). In another study (Souza da Costa et al., 2022), the impact of direct dehydration processes was evaluated on the phenolic composition pattern in the skin, seeds and stem wastes obtained in the wine-processing chain. However, with the exception of a few examples in literature, systematic studies on the search for the more affordable conditions to obtain stable products with high concentrations of valuable phenolic compounds are more often disregarded. This represents an important knowledge gap to be filled, within a resource recovery perspective, where the critical appraisal of pre-treatment conditions is essential, while keeping the full exploitation of grape pomace economically feasible for industrial scale-up.

The obtained extracts are often analysed as such (Fontana et al., 2017; Luque-Rodríguez et al., 2007) or subjected to hydrolysis by either chemical or enzymatic methodologies (Ramirez-Lopez & DeWitt, 2014; Wang et al., 2010) to increase the extraction yield of the phenolic compounds. Strong acids such as HCl, combined with high temperatures, are commonly used for hydrolysis of polyphenol conjugates in grape pomace (Wang et al., 2010) with the risk of triggering undesirable side reactions.

A more selective hydrolysis is attainable through the use of enzymes, generally applied in the food industry to transform or modify the functional characteristics of a product, thanks to their hydrolytic action on specific cell wall components. For example, the hydrolysis of cell wall structure by cellulases, hemicellulases or pectinases, has been exploited during the preparation of red wine, to favour the release of pigments into the juice by reducing the time of maceration of the grape skin in the must (de Souza & Kawaguti, 2021). Dal Magro and co-workers compared the effect of different enzymatic preparations on the extraction of bioactive compounds as well as on the yield and quality of grape juice from Vitis labrusca L. variety Concord (Dal Magro et al., 2016).

However, very few examples in literature have been dedicated to enzymatic hydrolysis to cleave the sugar moiety of phenolic glycosides in grape pomace extracts (Ramirez-Lopez & DeWitt, 2014; Ramirez-Lopez et al., 2014). More in detail, the integration of non-conventional techniques with enzyme-assisted post-extraction treatments has been little explored for this waste matrix. Examples in literature concern the use of pectolytic enzymes with UAE to enhance the extraction efficiency of phenolic compounds during vinification (Osete-Alcaraz et al., 2019), as well as the integration of microwave- and enzyme-assisted extraction of phenolic compounds from olive pomace (Macedo et al., 2021). Zhu and co-workers recently showed how the combination of UAE with enzyme hydrolysis, to promote cell wall decomposition and expansion of the intercellular space, efficiently improved the extraction rate of biologically active substances from edible fungi by-products (Zhu et al., 2023).

Therefore, although the relevant papers existing in literature, what clearly emerges is the lack of a complete analytical protocol to improve the extractability of phenols from grape pomace.

Taking the above into account, the aforementioned aspects have been thoroughly explored in the present paper. Our study, in fact, aimed to develop a comprehensive analytical workflow and an improved strategy to maximize phenol extraction from grape pomace and improve their identification. Thus, if on the one hand this work intends to fill important gaps still existing in the scientific panorama, on the other hand, it aims to address methodological difficulties, which represent an economic burden on a larger industrial scale.

In this frame, the phenolic composition of hydroalcoholic extracts obtained by UAE and the impact of pre- and post-extraction treatments were evaluated. At this purpose, pomace from two different important Umbrian red wine grape cultivars, namely Cabernet Sauvignon and Merlot, was selected, and the results were compared. The effect of three UAE parameters and their potential interactions were preliminarily evaluated to establish the optimal extraction conditions. Untreated and dried samples (air-, oven- and freeze-drying) were extracted by applying the UAE conditions previously established as the most performing for the recovery of phenolic compounds. Finally, both chemical (via HCl) and enzymatic (via β-glucuronidase) post-extraction hydrolysis were evaluated for the two grape varieties. For all samples, the antioxidant activity was measured by in vitro spectrophotometric assays. An optimized HPLC–DAD method was applied for qualitative profile monitoring and quantitative analysis of identified phenols, while a targeted LC-HRMS approach was performed to confirm the identity of the phenolic compounds. Finally, a cytotoxicity assay was performed on two extracts subjected to enzymatic hydrolysis, in order to obtain preliminary information regarding the safety of the extracts.

Material and Methods

Materials

Pomace of red wine grapes (Vitis vinifera L.) of Cabernet Sauvignon and Merlot varieties was obtained from the farm “Chiorri Azienda Agricola” (43.0035 and 12.3564 latitude and longitude, respectively; Sant’Enea, Perugia, Umbria, Italy).

Folin-Ciocalteu reagent, 2,2′-azino-bis(3-ethylbenzothiazoline-6-sulphonic acid) diammonium salt (ABTS), (±)-6-hydroxy-2,5,7,8-tetramethylchromane-2-carboxylic acid (Trolox), 2,4,6-tris(2-pyridyl)-s-triazine (TPTZ), 2,2-diphenyl-1-picrylhydrazyl (DPPH), hydrochloric acid (HCl), β-glucuronidase from Helix pomatia type HP-2, sodium acetate, dimethyl sulfoxide (DMSO), HPLC-grade and HPLC–MS grade methanol and formic acid were from Sigma-Aldrich (Milan, Italy). Water was purified by using a Milli-Q Plus 185 system from Millipore (Milford, MA, USA).

Vanillic acid, gallic acid, p-coumaric acid, syringic acid, resveratrol, (+)-catechin and epicatechin standards were from Sigma-Aldrich (Milan, Italy). Caffeic acid, ferulic acid, quercetin and kaempferol standards were purchased from Extrasynthese (Genay, France).

Silica gel [pore size 60 Å 0.063–0.200 mm (70–230 mesh ASTM)] for column chromatography, Millipore® was purchased from VWR International Srl (Milan, Italy).

Grape Pomace Preparation

Grape pomace (GP) obtained from Cabernet (C-GP) and Merlot (M-GP) comprised residual grape seeds, stems, pulp and skins obtained after winemaking fermentation. For each variety, three aliquots were prepared and submitted to different drying pre-treatments as follows.

Air-dried GP (CA-GP and MA-GP) was obtained after 8 days of air exposure dehydration. Oven-dried GP (CO-GP and MO-GP) was obtained after 4 h of dehydration in a ventilated oven (Binder, Series ED, BINDER GmbH, Tuttlingen, Germany) at 40 °C until a constant weight was reached. Freeze-dried GP (CL-GP and ML-GP) was obtained after 3-day lyophilisation (VirTis Benchtop 2 K Freeze Dryer, SP Industries Inc., Gardiner, NY, USA; chamber parameters: condenser temperature, − 70 °C; pressure value, 250 mTorr).

In all cases, a water loss of approximately 65% for the Cabernet variety and of 60% for the Merlot one was measured. The experimental results were compared with those obtained using the fresh material (CF-GP and MF-GP).

To obtain a rapid size reduction of GP samples, the Ultra Centrifugal mill ZM 200 (Retsch GmbH, Haan, Germany; mesh size of the sieve: 500 µm) was used, and the powdered samples were stored in amber vials in the dark until subsequent extraction and analytical characterization.

UAE of Phenol Compounds from Grape Pomace

Extraction of phenolics from GP was carried out with an ultrasonic bath (Model AU-65, by ARGOLAB, Carpi, Italy). A preliminary ultrasound-assisted extraction (UAE) was performed for 15 min by using an ethanol/water-50:50 (v/v) mixture containing variable percentages (in volume) of formic acid as additive (from 0 up to 1.5%). The solid/solvent ratio was fixed at 1:20 (g/mL), and the bath temperature was maintained at 30 °C. MA-GP was used to make this initial assessment. Extracts were centrifuged at 530 g for 15 min at room temperature (Neya 8, REMI, Mumbai, India), then supernatants were filtered and the solvent evaporated. The yield (measured as % recovery), total phenol content (TPC) and in vitro total antioxidant capacity (TAC, measured through ABTS, DPPH and FRAP assays) were used to compare the extraction efficiency among the solvent systems differing in the acidic additive content. The same parameters were used to evaluate the efficiency of an aqueous acetone-based extraction system [50:50 (v/v) containing 1% (v/v) formic acid].

UAE Optimization by Experimental Design

Once established the optimal formic acid concentration, an experimental design using MODDE 5.0 (UMETRICS AB, Umeå, Sweden) software was applied to evaluate the influence of three independent parameters (water content, ranging between 20 and 80%; sonication time, ranging between 10 and 30 min; temperature, ranging between 35 and 60 min), setting 1:20 g/mL as solid/solvent. The selected full factorial design (two levels) indicated a total of 11 experiments, with three experiments for the replication of the central point (N 1–11, details are reported in Table S1, Supplementary Information). The total phenol content (TPC) was selected as the response (dependent variable) of the experimental design. ML-GP was used to make this assessment. After UAE extraction, all samples were centrifuged at 530 g for 15 min at room temperature, and the supernatants were filtered and evaporated under vacuum until subsequent experiments. The effects of any unexplained variability in the observed response were minimized by randomizing the order of experiments.

Hydrolysis of Phenols in Grape Pomace Extracts

Hydrolysis of GP extracts was performed on each sample to convert glycosylated compounds to their respective aglycones. For the acidic hydrolysis, the dried extracts were resuspended in 35 mL of methanol/water-50:50 (v/v). An aliquot of 10 mL was treated with an equal volume of a mixture consisting of methanol/water/2N HCl-50/33/17 (v/v/v). Three different experimental conditions were screened: 1 h at 60 °C, 2 h at 60 °C and 1 h at 90 °C. Samples were placed in a water bath at the selected temperature and kept under constant stirring. At the end of the reaction, hydrolysed samples were cooled and filtered through a 0.2-µm syringe nylon filter.

The enzymatic hydrolysis was achieved with β-glucuronidase, according to the procedure developed by Mattioli et al. (2017) with modifications as follows: 500 µL of an aqueous solution of sodium acetate (pH 5) was added to 6 mg of dried extract. Then, 50 µL of β-glucuronidase was added to the aqueous residue, and the mixture was left incubating overnight at 37 °C. The reaction was quenched with the addition of 350-µL water, 100-µL 1 N HCl and 400 mg of NaCl and vortexed for 30 s. Column chromatography with silica gel (1.4 g for 10 × 200 mm glass column) was performed for subsequent purification. After loading the hydrolysed mixture, the aglycone fraction was eluted with 4 mL ethyl acetate. The eluate was dried under a gentle stream of nitrogen and solubilized in 500 µL of methanol before HPLC analysis.

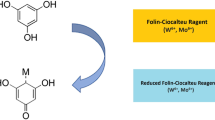

TPC and In Vitro TAC

The determination of total phenol content (TPC) and total antioxidant capacity (TAC) was performed according to our recent studies (Ianni et al., 2022; Mangiapelo et al., 2023; Pollini et al., 2021). TPC was determined using the Folin and Ciocalteu’s phenol reagent, and the absorbance was spectrophotometrically measured at 765 nm. Quantification was made by relying upon a calibration curve of gallic acid (y = 11.98x − 0.0229), and the results were expressed as mg gallic acid equivalents per gram of dry weight GP (mg GAE/g DW). A good linearity of the calibration curve was found as expressed by the high R2 values (> 0.999) in the 6.25–75 µg/mL concentration range.

TAC was evaluated through the free radical-scavenging activity using DPPH and ABTS assays, and through the reducing capacity evaluated with the FRAP assay. For all the three assays, quantification was made with a calibration curve using Trolox as surrogate standard, and the results were expressed as mg of Trolox equivalents per gram of dry weight GP (mg TE/g DW). All spectra were recorded with a LAMBDA™ UV–Vis spectrophotometer (PerkinElmer, Inc; Waltham, MA, USA).

The DPPH reagent was incubated with the extract sample for 30 min, and the absorbance was measured at 517 nm. The Trolox calibration curve (y = − 1.6006x + 0.6393) showed a good linearity (R2 > 0.999) in the investigated concentration range (1–250 µg/mL).

ABTS reagent was freshly prepared and incubated with the extracts for 6 min in the dark. The absorbance was measured at 734 nm. The calibration curve (y = − 1.6805x + 0.6873) showed a good linearity (R2 > 0.999) in the investigated concentration range (20–300 µg/mL).

FRAP assay was carried out by incubating the extract with the Fe3+-TPTZ complex for 30 min to achieve the ferric reduction, then the absorbance was measured at 593 nm. The calibration curve (y = 9.5883x − 0.0145) showed a good linearity (R2 > 0.999) in the investigated concentration range (12.5–100 µg/mL).

Chromatographic Analysis by HPLC–DAD

A HPLC–DAD method was optimized to evaluate the qualitative and quantitative profile of the investigated GP extracts. Measurements were made on a Thermo Separation low-pressure quaternary gradient pump system, supplied with a SpectraSystem SCM1000 Vacuum Membrane Degasser and coupled to a Spectra system UV 6000 LP diode array detector (DAD) (Thermo Scientific, Waltham, MA, USA), and a Rheodyne7725i injector (Rheodyne Inc., Cotati, CA, USA) with a 20-μL stainless steel loop. Data acquisition was done by the Excalibur software (Chromatographic Specialties Inc., Brockville, ON, Canada). A Robusta C18 column (250 × 4.6 mm i.d., 5 μm, 100 Å pore size, from SepaChrom, Rho, Milan, Italy) was used as the analytical column. The column was conditioned for 20 min before use with the optimized mobile phase. The following best gradient program was applied: eluent A (water/formic acid, 0.1% v) and eluent B (MeOH): 0 min — 100% A, 25 min — 70% A, 40 min — 60% A, 55 min — 40% A, 70 min — 70% A. The flow rate was set at 0.7 mL/min, and the column temperature was 25 °C.

Quantification of multiple classes of phenol compounds was performed through the external standard method by relying upon calibration curves built up for a few major compounds selected as representative of a specific class. Gallic acid was quantified setting the instrument at 250 nm and used as an external standard for quantification of phenolic acids including p-coumaric, syringic, protocatechuic, vanillic and ferulic acids at 300 nm. Quercetin was used for quantification of flavonoids such as (+)-catechin and (−)-epicatechin at 250-nm wavelength and as such and for kaempferol at 350 nm. Caffeic acid calibration curve was evaluated at 300 nm. Resveratrol was used as an external standard for quantification of stilbenes at 300 nm. Results of quantified compounds were expressed mg/g on the dry weight of grape pomace.

Data on calibration curves, at the most representative wavelengths are available in Table S2 (Supplementary Information).

Chromatographic Analysis by LC-QtoF

LC–MS/MS analyses for the structural confirmation of identified peaks were made on an Agilent 1290 Infinity II LC system coupled to an Agilent 6560 Ion Mobility Q-ToF LC/MS (Agilent Technologies, Santa Clara, CA, USA) and equipped with a Dual Agilent Jet Stream Electrospray Ionization (Dual AJS ESI) source. Data files were evaluated by using the Mass Hunter Workstation software 4.0 (MH) from Agilent. HPLC separations were performed at a temperature of 30 °C using a Zorbax Eclipse Plus C18 Rapid Resolution column (2.1 × 50 mm, 1.8 µm) and a reversed-phase mobile phase gradient. The gradient program obtained using eluent A [0.1% (v/v) formic acid in water] and eluent B (methanol) at a flow rate of 250 µL/min was set up as follows: initial composition of 98% A, held for 2.4 min, 60% A from 2.4 to 18 min, 30% A from 18 to 20.4 min, held for 0.6 min prior to returning to 98% A, held for 3 min (total run time of 24 min). Analyses were conducted in a negative and positive ion mode, and full scan spectra were obtained in the range of m/z 50–1000.

Nitrogen was used as drying gas at a temperature of 360 °C, a source gas temperature of 225 °C and a sheath gas flow rate of 12 L/min. The nebulizer gas pressure was 30 psi, the MS capillary voltage was 3500 V, the nozzle voltage 500 and the fragmentor was set to 275 V, octopole RF peak at 750 V and MS/MS collision energy of 20 eV. Mass calibration was performed immediately prior to measurements using the supplied tune mixture of the manufacturer made of an acetonitrile/water (95:5 v/v) solution containing 5 µM of purine (121.0509 m/z) and 2.5 µM of hexakis-(1H,1H,3H-tetrafluoro-pentoxy) phosphazene) (922.0098 m/z).

Cell Cultures and Cell Viability Assay

The human epithelial cell line of colorectal adenocarcinoma, Caco2, was obtained from the American Type Culture Collection (ATCC, Manassas, VA, USA). Cells were cultured in RPMI-1640 medium, supplemented with 10% heat-inactivated Fetal Bovine Serum (FBS), 2 mM of L-glutamine and antibiotics (100 U/mL penicillin, 100 μg/mL streptomycin). Incubations were performed at 37 °C in a 5% CO2 atmosphere and humidified air. In the experiments, 1 × 104 Caco2 cells (1 × 105 cells/mL) were seeded in each well of 96-well plates and incubated overnight before treatment. The day after, cells were treated with scalar amounts of Merlot grape pomace (ML) and Cabernet grape pomace (CL) dried hydrolysed extracts, re-suspended in DMSO. Cells untreated represented 100% viability, and cells treated with an equal volume of DMSO alone were used as controls. The cell viability of Caco2 cells was measured by an MTT assay. After 24-h incubation with stimuli (grape pomace extracts at 100, 30, 10, 3, 1 and 0.1 μg/mL), cells were incubated for 4 h at 37 °C with 110 μL of medium containing MTT 50 μg. After the addition of 100 μL of solubilisation buffer (SDS 10% —v/v— in HCl 0.01 M) to each well and an overnight incubation at 37 °C, the absorbance was read at 570 nm by a UV/visible spectrophotometer (TECAN, Thermo Fisher Scientific, Waltham, MA, USA). The assay was performed in triplicate for each concentration.

Statistical Analysis

The results are expressed as mean value ± standard deviation (n = 3). Statistical significance differences among group means were evaluated by one-way analysis of variance (ANOVA) followed by post hoc Tukey’s for multiple comparison tests. OriginPro 9.0 (OriginLab Corporation, Northampton, MA, USA) used as statistical software. The significance of the results was considered at p-value < 0.05. Means in the same column with different uppercase letters were significantly different. Same letters in the same column refer to means not statistically different according to ANOVA and Tukey’s test.

In cell viability assays, statistical significance differences were evaluated by one-way ANOVA.

Results and Discussion

Preliminary Evaluation of the Formic Acid Content and of the Organic Component (in the Extraction System)

As well known, solvent extraction composition and pH value can have a great influence on phenol recovery (Pintać et al., 2018; Barros Helena et al., 2019). In the context of selecting the best extraction solvent, hydroalcoholic mixtures based on methanol or ethanol or water–acetone systems have usually proved to be among the most suitable (Pintać et al., 2018; Zhong et al., 2019). Furthermore, acidification of the extraction medium, e.g. with formic, acetic or hydrochloric acid, has usually been associated with improved efficiency (Barros Helena et al., 2019; Mangiapelo et al., 2023; Ravindranath et al., 2021).

In line with this evidence, and aware that the wide variety of phenols in GP requires the need to establish an appropriate system for their efficient extraction (Pintać et al., 2018), specific conditions were iteratively tuned according to a one-variable-at-time (OVAT) approach. The first goal of this preliminary optimization step was to define the most fruitful acidic additive content. Accordingly, we selected formic acid, ranging from 0% to 1.5% (v/v), in a water/ethanol-50:50 (v/v) system. The choice of formic acid was guided by its greater effectiveness recently reported in literature (Barros Helena et al., 2019) in a study aimed at comparing different acid additives in the recovery of phenols and anthocyanins from Jabuticaba peel (Plinia cauliflora).

Based on our recent results, UAE was applied as the elective technique for the extraction of phenol compounds (Ianni et al., 2022; Mangiapelo et al., 2023; Pollini et al., 2021) and was carried out for 30 min. The MA-GP sample was chosen for this preliminary evaluation with a solid/solvent ratio of 1:20 (g/mL). The five acid concentrations were compared in terms of extraction yield, TPC and in vitro bioactivity (TAC measured through the ABTS, DPPH and FRAP assays). The results are shown in Table 1.

As evident from the data in Table 1, the yield values (%) linearly increased with the formic acid content showing the lowest value, i.e. 8.45%, in the absence of additive, and the highest one (12.46%) when the 1.0% (v/v) of formic acid was added to the hydroalcoholic system. This result repeated similarly in the in vitro assays (TPC, ABTS, DPPH and FRAP) the trend of which is reported in Table 1. More specifically, a similar behaviour was recorded when formic acid was added at 0.1 and 1.0% which provided the highest values, while a decrease occurred at the 1.5% concentration in all cases. Taking into account the slight improvement in all measurements in the presence of 1.0% formic acid, this concentration was chosen for successive experiments. The results obtained in this preliminary evaluation were in line with those reported by González and co-workers (González et al., 2020) who obtained a TPC value of 21.6 ± 3.8 mg GAE/g and an ABTS value of 35.8 ± 5.4 mg TE/g on fresh Tannat GP samples (extraction conditions: ethanol/water: 50:50 (v/v), mass to solvent ratio 1:20 (g/mL), 50 min UAE, 30 °C). Furthermore, these values were in the order of those obtained for oven-dried Tannat skin residues as reported by the same authors.

The complexity of phenol classes that could affect their selective solubility in the different solvents prompted us to consider the role of solvent polarity. Aqueous solutions of ethanol, methanol or acetone are generally more effective than a single-component solvent system for the extraction of phenols. Yilmaz and co-workers reported that an aqueous mixture of 50% or 75% acetone was better for the extraction of phenolic constituents from Muscadine seeds than a methanol or ethanol-based mixture (Yilmaz & Toledo, 2006). A similar result was also showed by Downey and Hanlin, who generally found acetone–water mixtures more performing solvents than ethanol–water for the extraction of condensed tannins from grape skin, while equal efficacy was found in a concentration range from 50 to 70% (v/v) (Downey & Hanlin, 2010). Within this frame, a further trial of this early phase of the study concerned the comparison of acetone with ethanol, used in the same experimental conditions (Table 1).

Under the conditions adopted in the present study, ethanol revealed higher extracting effectiveness than acetone. This result could represent an added value, being ethanol categorized as a green solvent since it can be obtained from renewable resources, further strengthened by the combination with UAE as an alternative and green approach for the recovery of phenolic compounds (Goula et al., 2016; Tiwari, 2015).

Among the factors affecting the extraction efficiency, the number of steps should be considered: this parameter, in fact, can influence the recovery of phenol compounds as well as the antioxidant potential of the extracts (Złotek et al., 2016). Therefore, UAE performance obtained with a single-step for 30 min was compared with a double-step extraction of 15 min each while refreshing the solvent. More in details, in the first case, the MA-GP sample was treated with a water/ethanol-50:50 (v/v) mixture containing 1.0% (v/v) formic acid using a solid/solvent ratio of 1:20 (g/mL). In the second case, two consecutive extractions were carried out using a solid solvent ratio of 1:10 (g/mL): in the first extraction cycle, the supernatant was collected after the centrifugation, while the residue was re-extracted with further 10 mL of fresh solvent for the second cycle. In this last situation, at the end of both extractions, the supernatants were combined. The results measured in terms of yield (%) and TPC showed the double-step procedure being slightly more effective for the recovery of phenolic compounds. In fact, a single extraction of 30 min provided an average yield of 13.8% and a TPC value of 23.30 ± 0.11 mg GAE/g DW while the double-step procedure allowed to obtain a total average yield of 19% and a TPC value of 25.98 ± 0.44 mg GAE/g extract. However, since a tangible increment was not recorded, for ease of operation, the single extraction was considered for the successive steps of the study.

Chemical Hydrolysis by Hydrochloric Acid

Acidic hydrolysis of grape pomace extracts was investigated to convert phenol glycosides to the respective aglycones. The extracts obtained from MA-GP samples were subjected to three different reaction conditions with 2N HCl (1 h and 2 h at 60 °C, 1 h at 90 °C). The results showed that the latter hydrolysis condition affected the process more favourably. This outcome reported in Fig. S1 (Supplementary Information) readily shows the improved baseline separation among detected peaks (obtained after incubation at 90 °C), allowing their better identification. Similar considerations were reported by Wang and co-workers (Wang et al., 2010) who described the effectiveness of strong acid hydrolysis in releasing free phenolics from bound ones, applied to the analyses of muscadine pomace extract. By taking into account the effects of hydrolysis time and temperature on the content of identified phenols (measured as area values, data not shown), a change in the chromatographic profile was recorded when the hydrolysis temperature was raised from 60 to 90 °C. Whilst only negligible differences in the chromatographic profiles were observed at 60 °C compared to the non-hydrolysed extract. Instead, the direct addition of HCl solution to the hydroalcoholic extraction system (water/ethanol-50:50, v/v), under stirring at 90 °C for 1 h did not provide any significant improvement (data not shown).

UAE Optimization by Experimental Design

It is well known that the maximization of extraction results is closely related to several parameters. For this reason, at this stage of the study, we considered necessary to pursue a chemometrical approach to reach a detailed exploration of the extraction system, which cannot be easily managed via a simple OVAT methodology. In this case, an experimental design that enables a global understanding of the system with a smaller number of experiments would be more appropriate. Starting from the results attained in the early evaluations, the Experimental Design software MODDE® 5.0 (UMETRICS, Umeå, Sweden) was applied to evaluate the influence of three independent parameters (water content in ethanol, extraction time and temperature) on the UAE of phenols from GP. The TPC measured by spectrophotometry was selected as the response. The design matrix and the experimental results are shown in Table S1 (Supplementary Information). The results of the experimental design showed that a combination of the highest ethanol content (80%, v/v) and extraction time (30 min) with the lowest temperature (35 °C) yielded the extract with a higher TPC compared to the other conditions. Such results are clearly represented in Fig. 1. In all experiments, TPC values higher than that reported by Romanini and co-workers (Romanini et al., 2021), i.e. 24.63 ± 0.28 mg of GAE/g, obtained by applying the best extraction conditions (water as a solvent, 55 °C, 6 min of UAE treatment) were recorded.

Moreover, the factors optimized in the present study revealed slight differences compared to other data reported in literature. In fact, the experimental design recently described to evaluate the recovery of phenolic compounds from GP by UAE (Drevelegka & Goula, 2020; Cúcúz et al., 2022) showed that an increase in temperature (around 55–56 °C) corresponded to a better extraction efficiency related to the enhanced solubility of the extracted compounds and diffusion coefficient. In both studies, also the influence of ethanol concentration on the extraction as well as of time was evaluated. In these cases, the authors found that the extraction yield increased until an ethanol concentration ranging between 50 and 55% and then started to decrease with a further increase in the ethanol concentration; the optimal extraction time was fixed at 20 min (Drevelegka & Goula, 2020) or 30 min (Cúcúz et al., 2022).

Interestingly, the data obtained in our study, particularly regarding the application of the lowest temperature, make the process more energy saving, allowing the integrity of polyphenols to be preserved.

Figure 1A shows the coefficients of the three selected factors and their influence on the response. More in detail, the factor “solvent composition” (water content in ethanol) markedly influenced the response in a negative manner. Conversely, the “time factor” had a positive influence on the response, followed, marginally, by the “temperature factor”. In this frame, the factor water content * time interaction had a negative influence on the TPC mainly driven by the generally higher effect for water content than time. A negligible effect was instead observed for interactions involving temperature as a factor.

The response surface plot shown in Fig. 1B highlights how the decrease of water % in ethanol and the increase of time correspond to better TPC response. Moreover, the satisfactory values obtained for the two statistical parameters R2 (which describes how well the model fits the experimental data, R2 = 0.802) and Q2 (which describes how well the model will predict new data, Q2 = 0.535), indicated the high quality of the statistical model and its usability for optimization and prediction purposes.

Chemical vs Enzymatic Hydrolysis

Complex matrix extractions typically require performing hydrolysis procedures to simplify the chromatographic data (Wang et al., 2018). With the aim of avoiding the harsh conditions necessary for chemical approaches, the feasibility of the enzymatic hydrolysis as an alternative route was considered. Accordingly, the purpose of this stage of the project was to evaluate the efficiency of β-glucuronidase catalysed hydrolysis to determine the phenolic composition of grape pomace extracts and to make a comparison with that provided by the HCl-hydrolysed, under the best identified extraction conditions.

Very few examples are reported in literature on the use of β-glucuronidase in hydrolytic treatments of flavonoid glycosides as an in vitro system to determine and mimic in vivo biological activities (Fiechter et al., 2013). As additional feature, the enzyme from Helix pomatia is often associated with sulfatase activity, which can support the processes of cleavage and deconjugation of glycosides (Ramirez-Lopez et al., 2014).

The chromatographic profiles obtained after β-glucuronidase treatment on ML-GP and CL-GP are exemplarily shown in Fig. 2. Compound identification was based on the comparison of their UV spectra and retention times with reference standards.

HPLC–DAD (selected wavelength 250 nm) chromatograms of free phenolic compounds extracted from A ML-GP and B CL-GP samples after β-glucuronidase hydrolysis. The magnified sections show the profile of selected phenols at wavelengths of 300 nm (p-coumaric acid, ferulic acid, resveratrol) and 350 nm (quercetin and kaempferol)

Enzymatic hydrolysis strongly influenced the phenolic recovery from grape pomace extracts. In fact, moChromatographic analysis by HPLC-DADre individual phenolics were identified than in non-hydrolysed or HCl-hydrolysed samples. Moreover, one main challenge encountered in the chemical treatment was the overlapping elution of analytes of interest with unidentified compounds or matrix interferences. Therefore, the quantitative analysis for extracts subjected to HCl-hydrolysis focused exclusively on gallic acid, protocatechuic acid, syringic acid and resveratrol. However, even for these phenolic compounds, spectral profiles showed a slight deviation from the reference spectrum, probably originating from other impurities. This would lead to the overestimation of peaks of interest. Such drawback did not arise after the hydrolysis with β-glucuronidase, where the spectral matching to the pure samples underlines the remarkable contribution of a more selective linkage hydrolysis in bound phenolics, thereby promoting the release of their aglycone forms. The following purification step contributed to provide a “clean” spectrum. On this basis, the quantitative result is more reliably assigned to an identified component. Therefore, from a practical point of view, enzymatic hydrolysis could be approached as more profitable to be performed as compared to the acidic one. In Table 2, the quantitative results for identified phenols are presented. As described in “Chromatographic Analysis by HPLC–DAD”, when reference compounds were not available, the calibration of structurally related substances was used.

Where comparisons are feasible, with the sole exception of protocatechuic acid, enzymatic hydrolysis yielded, on average, larger amounts of phenolic compounds: a high variability emerged for each analyte in the two investigated grape pomace varieties, according to the hydrolysis approach. Noteworthy, if the total phenol content is considered for each sample, freeze-dried ones (namely ML-GP and CL-GP) showed the highest value (1904.08 and 2064.64 mg/g DW, respectively) with a major contribution from p-coumaric acid and gallic acid. This highlights the successful use of freeze-drying to promote the retention and protection of these bioactive compounds.

Selection of the Sample Treatment Method

The variation in the composition of potential biologically active compounds as a function of the different sample treatments was evaluated. The best extraction conditions, followed by further chemical or enzymatic treatment, were applied to identify a possible interrelationship between the recovery of phenols from fresh or air-dried, freeze-dried and oven-dried grape pomace with the TPC and the TAC of the extracts. The comparison was made on the two different varieties of red grape pomace (Merlot and Cabernet) under study with respect to the non-hydrolysed samples (Table 3).

In general, regarding to the non-hydrolysed samples, both varieties shared a similar behaviour showing a parallel trend in the spectrophotometric response. In particular, as readily evident from data in Table 3, fresh and freeze-dried samples displayed the highest antioxidant power compared to the other samples, with a particularly high radical scavenging activity measured by ABTS. A different and complex situation arose when grape pomace extracts subjected to either chemical or enzymatic hydrolysis were characterized as regards their TPC and TAC values (Table 3).

Although the hydrolysis provided a simplified chromatographic profile with respect to the non-hydrolysed samples, which is important for identification purposes, the spectrophotometric assays noticeably showed different results. What emerged in this case was a higher TPC value and reducing power measured by FRAP observed for the chemically hydrolysed oven-dried samples (MO-GP and CO-GP) related to the non-hydrolysed ones. Generally, slightly higher DPPH values were obtained in almost all cases where acid-driven hydrolysis was carried out, whilst a drastic reduction of the ABTS results was recorded. These outcomes are promptly viewable in Fig. S2 (Supplementary Information).

A different situation occurred when the enzymatic hydrolysis by β-glucuronidase was carried out. Concerning the Merlot variety, the highest TPC values well correlated with the TAC ones for MA-GP extracts, followed by ML-extracts. This result somewhat paralleled the trend observed with the analogous samples under non-hydrolysed conditions. Conversely, a controversial behaviour regarded the Cabernet variety for which a greater variability was highlighted and only CF-GP, CA-GP and CO-GP samples showed a parallel trend when submitted to ABTS and FRAP assays.

What stands out here is the extraordinarily superior performance achieved in all the assays after enzymatic hydrolysis. Hydrolysis of complex polyphenols into simpler phenols could increase the amount of bioactive substances available. Furthermore, in contrast to the chemical treatment, these results could be also plausibly attributable to the more selective enzyme-driven hydrolysis, which preserves the chemical integrity of bioactive compounds by removing matrix species that adversely interfere with the reaction mechanisms involved in the assays (Huang et al., 2005).

A significant linear relationship (Fig. S3, Supplementary Information) was observed between TPC and TAC values with high correlation coefficients for non-hydrolysed samples and high correlation, with respect to the ABTS and FRAP assays, for the HCl-hydrolysed samples. The lack of correlation between total phenolics and antioxidant assays demonstrated by enzymatic hydrolysed samples reflects the high differences in the phenolic composition among the extracts as clearly evidenced by the results of the HPLC analyses.

Based on the results obtained, this study once again points out the need to appraise the potential impact of sample pre-treatment processing on the recovery and activity of bioactive compounds.

Phenol Identity Confirmation by LC-HRMS/MS Analysis

The qualitative profile of polyphenol components after β-glucuronidase hydrolysis obtained by HPLC–DAD was evaluated via a targeted metabolomic approach using high-resolution mass spectrometry. Each compound was identified by comparing m/z values obtained in MS and MS/MS experiments with the mass spectra obtained from the pure compounds tested in the same conditions, and by comparison with data reported in literature. The profile of major phenolic compounds identified by LC–MS in negative mode is reported in Table S3 (Supplementary Information). Data are referred to CL-GP selected as an exemplary extract. Targeted metabolite profiling by LC–MS confirmed the identity of the expected metabolites.

The results confirm the attractiveness of such approach in food analysis for a more reliable identification of a pre-known and well-established set of metabolites.

Cytotoxicity Assessment

Caco2 is a human epithelial cell line widely used as a model of the intestinal epithelial barrier (Knipp et al., 1997; Tang et al., 1993). With a view to using grape pomace as a food supplement, we evaluated any potential toxic effect of the two freeze dried extracts from grape pomace, i.e. CL-GP and ML-GP both subjected to enzymatic hydrolysis, by means of a MTT assay. The MTT reagent (3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyl-2H-tetrazolium bromide) is a mono-tetrazolium salt that consists of a positively charged quaternary tetrazole ring core containing four nitrogen atoms surrounded by three aromatic rings including two phenyl moieties and one thiazolyl ring. The MTT reagent can pass through the cell membrane, as well as the mitochondrial inner membrane, of viable cells, and is reduced to a violet, water-insoluble compound called formazan by metabolically active cells (Berridge et al., 2005). After the incubation with MTT, cellular membranes are lysed, and the water-insoluble formazan eventually produced is released in the culture medium. Subsequently, the absorbance of the formazan-containing medium is measured by a microplate reader in terms of its optical density (OD) at a wavelength which MTT-derived formazan absorbs the most (i.e. 570 nm). The measured OD values are representative of the formazan concentration and consequently of the intracellular reduction of MTT. Then, MTT assay is a common tool used to determine drug cytotoxicity by measuring the metabolic activity of cells, which is an indicator of cell proliferation and viability, as well as cytotoxicity (Stockert et al., 2018). More in detail, we exposed Caco2 cultures to a range 0.1–100 μg/mL of each extract for 24 h, and then we performed the MTT assay. As showed in Fig. 3, no cytotoxic effect from any of the extracts was detected at any of the tested concentrations. Indeed, the viability of the Caco2 cells exposed to each concentration of the two extracts was comparable to the viability of cells treated with vehicle alone (DMSO). The obtained results proved to be highly encouraging and promising compared with data recently reported by other authors (Calabriso et al., 2022), in which exposure of Caco2 cells to increasing concentrations of GP extracts for 24 h revealed toxic at concentrations of 25 µg/mL compared to the vehicle control measured by the MTT assay. This result confirms the safety of the two extracts obtained by enzymatic hydrolysis and could pave the way for a further characterization of the efficacy of these extracts as food supplements, as well as natural colorants, food preservatives and in the development of functional foods.

Cell viability analysed by MTT assay on Caco2 cells treated with CL and ML extracts subjected to enzymatic hydrolysis. Caco2 cells were treated for 24 h with grape pomace extracts at the indicated concentrations. The percentage of viable cells with respect to DMSO-treated cells used as control was evaluated by MTT assay and reported as the mean ± standard deviation of three independent experiments, each conducted in triplicate. Dotted line indicates viability of DMSO-treated cells (one-way ANOVA test)

Conclusions

In this study, a comprehensive analytical strategy for polyphenol extraction and identification was implemented. Pomace from two important Umbrian red wine grape cultivars, namely Cabernet Sauvignon and Merlot, was selected. In order to explore the potential of the processing workflow, specific conditions were iteratively tuned by comparing the polyphenol recovery from fresh, air-dried, freeze-dried and oven-dried grape pomace submitted, or not, to hydrolysis. The UAE extraction of phenols from grape pomace was properly optimized through an Experimental Design. The evaluation of the influence of three independent variables on TPC selected as the response showed a negative impact of water content in ethanol and a positive influence of time, with a negligible influence of UAE temperature. Furthermore, the high statistical quality of the model suggests its usability for optimization and prediction purposes.

The chemical hydrolysis (by HCl) was compared with enzymatic-hydrolysis (by β-glucuronidase) in order to get the conversion of glycosylated compounds to their respective aglycones. The results, monitored via HPLC–DAD, showed simplified chromatographic profiles obtained after β-glucuronidase treatment. This in turn allowed for better identification, successively confirmed via LC-HRMS/MS analysis, and a reliable quantification of major phenols. The higher performance of enzyme-hydrolysed compared to HCl-or not-hydrolysed extracts was also corroborated by in vitro assays carried out to evaluate the total phenol content as well as the total antioxidant capacity. However, while fresh and freeze-dried samples from both non-hydrolysed varieties shared a similar spectrophotometric behaviour, a different situation arose when grape pomace extracts were subjected to either chemical or enzymatic hydrolysis. In general, based on the obtained results, it can be stated that the enzyme-driven hydrolysis could be selected as highly selective and integrity-preserving treatment when dealing with sensitive bioactive compounds.

This finding was further supported by the absence of cytotoxic effects tested on Caco2 cell viability from both the extracts subjected to β-glucuronidase treatment.

The inspiring results obtained in this work could be of practical aid for the handling of winery by-products and their fruitful use as a source of polyphenols for industrial applications. Accordingly, the potential properties of grape pomace extracts described here pave the way for their future fruitful inclusion in foods, allowing obtaining functional foods or nutraceuticals with beneficial effects to face unhealthy and unbalanced diets. This perspective fits well with a sustainable framework aimed at maximizing waste recycling in a circular bio-economy context by valorising and reshaping alternative resources inspired by the concept of “zero waste”.

Data Availability

All data generated or analysed during this study are included in this published article.

References

Armenta, S., Garrigues, S., Esteve-Turrillas, F., & de la Guardia, M. (2019). Green extraction techniques in green analytical chemistry. TrAC Trends in Analytical Chemistry, 116, 248–253. https://doi.org/10.1016/j.trac.2019.03.016

Barba, F. J., Brianceau, S., Turk, M., Boussetta, N., & Vorobiev, E. (2015). Effect of alternative physical treatments (ultrasounds, pulsed electric fields, and high-voltage electrical discharges) on selective recovery of bio-compounds from fermented grape pomace. Food and Bioprocess Technology, 8(5), 1139–1148. https://doi.org/10.1007/s11947-015-1482-3

Barros Helena, D. F. Q., Baseggio, A. M., Angolini Célio, F. F., Pastore Gláucia, M., Cazarin, C. B. B., & Marostica-Junior, M. R. (2019). Influence of different types of acids and pH in the recovery of bioactive compounds in Jabuticaba peel (Plinia cauliflora). Food Research International, 124, 16–26. https://doi.org/10.1016/j.foodres.2019.01.010

Beres, C., Costa, G. N. S., Cabezudo, I., da Silva-James, N. K., Teles, A. S. C., Cruz, A. P. G., Mellinger-Silva, C., Tonon, R. V., Cabral, L. M. C., & Freitas, S. P. (2017). Towards integral utilization of grape pomace from winemaking process: A review. Waste Management, 68, 581–594. https://doi.org/10.1016/j.wasman.2017.07.017

Berridge, M. V., Herst, P. M., & Tan, A. S. (2005). Tetrazolium dyes as tools in cell biology: New insights into their cellular reduction. Biotechnology Annual Review, 11, 127–152. https://doi.org/10.1016/s1387-2656(05)11004-7

Calabriso, N., Massaro, M., Scoditti, E., Verri, T., Barca, A., Gerardi, C., Giovinazzo, G., & Carluccio, M. A. (2022). Grape pomace extract attenuates inflammatory response in intestinal epithelial and endothelial cells: Potential health-promoting properties in bowel inflammation. Nutrients, 14, 1175. https://doi.org/10.3390/nu14061175

Caldas, T. W., Mazza, K. E. L., Teles, A. S. C., Mattos, G. N., Brígida, A. I. S., Conte-Junior, C. A., Borguini, R. G., Godoy, R. L. O., Cabral, L. M. C., & Tonon, R. V. (2018). Phenolic compounds recovery from grape skin using conventional and non-conventional extraction methods. Industrial Crops and Products, 111, 86–91. https://doi.org/10.1016/j.indcrop.2017.10.012

Castellanos-Gallo, L., Ballinas-Casarrubias, L., Espinoza-Hicks, J. C., Hernández-Ochoa, L. R., Muñoz-Castellanos, L. N., Zermeño-Ortega, M. R., Borrego-Loya, A., & Salas, E. (2022). Grape pomace valorization by extraction of phenolic polymeric pigments: A review. Processes, 10, 469. https://doi.org/10.3390/pr10030469

Cúcúz, V., Cvejić, J., Torović, L., Gojković-Bukarica, L., Acevska, J., Dimitrovska, A., Aldawoud, T. M. S., & Galanakis, C. M. (2022). Design of experiments (DoE) to model phenolic compounds recovery from grape pomace using ultrasounds. Journal of Food Science and Technology, 59(7), 2913–2924. https://doi.org/10.1007/s13197-021-05317-9

Da Porto, C., & Natolino, A. (2017). Supercritical fluid extraction of polyphenols from grape seed (Vitis vinifera): Study on process variables and kinetics. The Journal of Supercritical Fluids, 130, 239–245. https://doi.org/10.1016/j.supflu.2017.02.013

Dal Magro, L., Goetze, D., Ribeiro, C. T., Paludo, N., Rodrigues, E., Hertz, P. F., Poletto Klein, M., & Rodrigues, R. C. (2016). Identification of bioactive compounds from Vitis labrusca L. variety concord grape juice treated with commercial enzymes: Improved yield and quality parameters. Food and Bioprocess Technology, 9, 365–377. https://doi.org/10.1007/s11947-015-1634-5

de Souza, T. S. P., & Kawaguti, H. Y. (2021). Cellulases, hemicellulases, and pectinases: Applications in the food and beverage industry. Food and Bioprocess Technology, 14, 1446–1477. https://doi.org/10.1007/s11947-021-02678-z

Downey, M. O., & Hanlin, R. L. (2010). Comparison of ethanol and acetone mixtures for extraction of condensed tannin from grape skin. South African Journal of Enology and Viticulture, 31(2), 54–159. https://doi.org/10.21548/31-2-1412

Drevelegka, I., & Goula, A. M. (2020). Recovery of grape pomace phenolic compounds through optimized extraction and adsorption processes. Chemical Engineering and Processing, 149, 107845. https://doi.org/10.1016/j.cep.2020.107845

Ebrahimi, P., Mihaylova, D., Marangon, C. M., Grigoletto, L., & Lante, A. (2022). Impact of sample pretreatment and extraction methods on the bioactive compounds of sugar beet (Beta vulgaris L.) Leaves. Molecules, 27, 8110. https://doi.org/10.3390/molecules27228110

Fiechter, G., Opacak, I., Raba, B., & Mayer, H. K. (2013). A new ultra-high pressure liquid chromatography method for the determination of total isoflavone aglycones after enzymatic hydrolysis: Application to analyse isoflavone levels in soybean cultivars. Food Research International, 50, 586–592. https://doi.org/10.1016/j.foodres.2011.03.038

Fontana, A., Antoniolli, A., D’Amario Fernández, M. A., & Bottini, R. (2017). Phenolics profiling of pomace extracts from different grape varieties cultivated in Argentina. RSC Advances, 7, 29446–29457. https://doi.org/10.1039/c7ra04681b

Garrido, T., Nikolaidis, M. G., Leceta, I., Urdanpilleta, M., Guerrero, P., la Caba, K., & Kilmartin, P. A. (2019). Optimizing the extraction process of natural antioxidants from chardonnay grape marc using microwave-assisted extraction. Waste Management, 88, 110–117. https://doi.org/10.1016/j.wasman.2019.03.031

González, M., Barrios, S., Budelli, E., Pérez, N., Lema, P., & Heinzenb, H. (2020). Ultrasound assisted extraction of bioactivecompounds in fresh and freeze-dried Vitis viniferacv Tannat grape pomace. Food and Bioproducts Processing, 124, 378–386. https://doi.org/10.1016/j.fbp.2020.09.012

Goula, A. M., Thymiatis, K., & Kaderides, K. (2016). Valorization ofgrape pomace: Drying behavior and ultrasound extraction ofphenolics. Food and Bioproducts Processing, 100, 132–144. https://doi.org/10.1016/j.fbp.2016.06.016

Huang, D., Ou, B., & Prior, R. L. (2005). The chemistry behind antioxidant capacity assays. Journal of Agricultural and Food Chemistry, 53(6), 1841–1856. https://doi.org/10.1021/jf030723c

Ianni, F., Barola, C., Blasi, F., Moretti, F., Galarini, R., & Cossignani, L. (2022). Investigation on chlorogenic acid stability in aqueous solution after microwave treatment. Food Chemistry, 374, 131820. https://doi.org/10.1016/j.foodchem.2021.131820

Knipp, G. T., Ho, N. F. H., Barsuhn, C. L., & Borchardt, R. T. (1997). Paracellular diffusion in Caco-2 monolayers: Effects of perturbants on the transport of hydrophilic compounds that vary in charge and size. Journal of Pharmaceutical Sciences, 86, 1105–1110. https://doi.org/10.1021/js9700309

Luque-Rodríguez, J. M., de Castro, L., & Pérez-Juan, P. (2007). Dynamic superheated liquid extraction of anthocyanins and other phenolics from red grape skins of winemaking residues. Bioresource Technology, 98, 2705–2713. https://doi.org/10.1016/j.biortech.2006.09.019

Macedo, G. A., Santana, A. L., Crawford, L. M., Wang, S. C., Dias, F. F. G., & de Moura Bell, L. M. N. J. (2021). Integrated microwave- and enzyme-assisted extraction of phenolic compounds from olive pomace. LWT, 138, 110621. https://doi.org/10.1016/j.lwt.2020.110621

Mangiapelo, L., Blasi, F., Ianni, F., Barola, C., Galarini, R., Abualzulof, G. W. A., Sardella, R., Volpi, C., & Cossignani, L. (2023). Optimization of ultrasound-assisted extraction of chlorogenic acid from potato sprout waste and enhancement of the in vitro total antioxidant capacity. Antioxidants, 12, 348. https://doi.org/10.3390/antiox12020348

Marchante, L., Alonso, S. G., Alañón, M. E., Pérez-Coello, M. S., & Díaz-Maroto, M. C. (2018). Natural extracts from fresh and oven-dried winemaking byproducts as valuable source of antioxidant compounds. Food Science & Nutrition, 6, 1564–1574. https://doi.org/10.1002/fsn3.697

Martìnez Garcìa, L., Ceccanti, C., Negro, C., De Bellis, L., Incrocci, L., Pardossi, A., & Guidi, L. (2021). Effect of drying methods on phenolic compounds and antioxidant activity of Urtica dioica L. leaves. Horticulturae, 7, 10. https://doi.org/10.3390/horticulturae7010010

Mattioli, S., Ruggeri, S., Sebastiani, B., Brecchia, G., Dal Bosco, A., Cartoni Mancinelli, A., & Castellini, C. (2017). Performance and egg quality of laying hens fed flaxseed: Highlights on n-3 fatty acids, cholesterol, lignans and isoflavones. Animal, 11(04), 705–712. https://doi.org/10.1017/s175173111600207x

Meinia, M. R., Cabezudo, I., Boschetti, C. E., & Romanini, D. (2019). Recovery of phenolic antioxidants from Syrah grape pomace through the optimization of an enzymatic extraction process. Food Chemistry, 283, 257–264. https://doi.org/10.1016/j.foodchem.2019.01.037

Moro, K. I. B., Beutinger Bender, A. B., da Silva, L. P., & Penna, N. G. (2021). Green extraction methods and microencapsulation technologies of phenolic compounds from grape pomace: A review. Food and Bioprocess Technology, 14, 1407–1431. https://doi.org/10.1007/s11947-021-02665-4

OIV, the International Organization of Vine and Win. (2022). https://www.oiv.int, last accessed May 20, 2023.

Osete-Alcaraz, A., Bautista-Ortín, A. B., Ortega-Regules, A. E., & Gómez-Plaza, E. (2019). Combined use of pectolytic enzymes and ultrasounds for improving the extraction of phenolic compounds during vinification. Food and Bioprocess Technology, 12, 1330–1339. https://doi.org/10.1007/s11947-019-02303-0

Pintać, D., Majkić, T., Torović, L., Orčić, D., Beara, I., Simin, N., Mimica-Dukić, N., & Lesjak, M. (2018). Solvent selection for efficient extraction of bioactive compounds from grape pomace. Industrial Crops and Products, 111, 379–390. https://doi.org/10.1016/j.indcrop.2017.10.038

Pollini, L., Ianni, F., Verducci, G., Blasi, F., & Cossignani, L. (2021). Is the household microwave recommended to obtain antioxidant-rich extracts from Lycium barbarum leaves? Processes, 9, 656. https://doi.org/10.3390/pr9040656

Ramirez-Lopez, L. M., & DeWitt, C. A. M. (2014). Analysis of phenolic compounds in commercial dried grape pomace by high-performance liquid chromatography electrospray ionization mass spectrometry. Food Science & Nutrition, 2(5), 470–477. https://doi.org/10.1002/fsn3.136

Ramirez-Lopez, L. M., McGlynn, W., Goad, C. L., & DeWitt, C. A. M. (2014). Simultaneous determination of phenolic compounds in Cynthiana grape (Vitis aestivalis) by high performance liquid chromatography–electrospray ionisation–mass spectrometry. Food Chemistry, 149(2014), 15–24. https://doi.org/10.1016/j.foodchem.2013.10.078

Ravindranath, V., Singh, J., Jayaprakasha, G. K., & Patil, B. S. (2021). Optimization of extraction solvent and fast bluE BB assay for comparative analysis of antioxidant phenolics from Cucumis melo L. Plants, 10, 1379. https://doi.org/10.3390/plants10071379

Romanini, E. B., Rodrigues, L. M., Finger, A., Cantuaria Chierrito, T. P., da Silva Scapim, M. R., & Madrona, G. S. (2021). Ultrasound assisted extraction of bioactive compounds from BRS violet grape pomace followed by alginate-Ca2+ encapsulation. Food Chemistry, 338, 128101. https://doi.org/10.1016/j.foodchem.2020.128101

Saifullah, R., McCullum, A., & McCluskey, Q. V. (2019). Effects of different drying methods on extractable phenolic compounds and antioxidant properties from lemon myrtle dried leaves. Heliyon, 5, e03044. https://doi.org/10.1016/j.heliyon.2019.e03044

Sirohi, R., Tarafdar, A., Singh, S., Negi, T., Kumar Gaur, V., Gnansounou, E., & Bharathiraja, B. (2020). Green processing and biotechnological potential of grape pomace: Current trends and opportunities for sustainable biorefinery. Bioresource Technology, 314, 123771. https://doi.org/10.1016/j.biortech.2020.123771

Sokač, T., Gunjević, V., Pušek, A., Tušek, A. J., Dujmić, F., Brnčić, M., Kovačević Ganić, K., Jakovljević, T., Uher, D., Mitrić, G., & Radojčić Redovniković, I. (2022). Comparison of drying methods and their effect on the stability of Graševina grape pomace biologically active compounds. Foods, 11, 112. https://doi.org/10.3390/foods11010112

Souza da Costa, B., Soldevilla Muro, G., Oliván García, M., & Motilva, M. J. (2022). Winemaking by-products as a source of phenolic compounds: Comparative study of dehydration processes. LWT - Food Science and Technology, 165, 113774. https://doi.org/10.1016/j.lwt.2022.113774

Stockert, J. C., Horobin, R. W., Colombo, L. L., & Blázquez-Castro, A. (2018). Tetrazolium salts and formazan products in cell biology: viability assessment, fluorescence imaging, and labeling perspectives. Acta Histochemica, 120, 159–167. https://doi.org/10.1016/j.acthis.2018.02.005

Tang, A. S., Chikhale, P. J., Shah, P. K., & Borchardt, R. T. (1993). Utilization of a human intestinal epithelial cell culture system (Caco-2) for evaluating cytoprotective agents. Pharmaceutical Research, 10(11), 1620–1626. https://doi.org/10.1023/a:1018976804403

Tao, Y., Zhang, Z., & Sun, D. W. (2014). Kinetic modeling of ultrasound-assisted extraction of phenolic compounds from grape marc: Influence of acoustic energy density and temperature. Ultrasonics Sonochemistry, 21, 1461–1469. https://doi.org/10.1016/j.ultsonch.2014.01.029

Tiwari, B. K. (2015). Ultrasound: A clean, green extraction technology. TrAC Trends in Analytical Chemistry, 71, 100–109. https://doi.org/10.1016/j.trac.2015.04.013

Wang, L., Luo, Y., Wua, Y., Liu, Y., & Wu, Z. (2018). Fermentation and complex enzyme hydrolysis for improving the total soluble phenolic contents, flavonoid aglycones contents and bio-activities of guava leaves tea. Food Chemistry, 264, 189–198. https://doi.org/10.1016/j.foodchem.2018.05.035

Wang, X., Tong, H., Chen, F., & Gangemi, J. D. (2010). Chemical characterization and antioxidant evaluation of muscadine grape pomace extract. Food Chemistry, 123, 1156–1162. https://doi.org/10.1016/j.foodchem.2010.05.080

Yilmaz, Y., & Toledo, R. T. (2006). Oxygen radical absorbance capacities of grape/wine industry byproducts and effect of solvent type on extraction of grape seed polyphenols. Journal of Food Composition and Analysis, 19, 41–48. https://doi.org/10.1016/j.jfca.2004.10.009

Zhong, L., Yuan, Z., Rong, L., Zhang, Y., Xiong, G., Liu, Y., & Li, C. (2019). An optimized method for extraction and characterization of phenolic compounds in Dendranthema indicum var. aromaticum Flower. Scientific Reports, 9, 7745. https://doi.org/10.1038/s41598-019-44102-9

Zhu, F., Du, B., Zheng, L., & Li, J. (2015). Advance on the bioactivity and potential applications of dietary fibre from grape pomace. Food Chemistry, 186, 207–212. https://doi.org/10.1016/j.foodchem.2014.07.057

Zhu, Y., Zhang, M., Law, C. L., Wang, Y., & Liu, K. (2023). Optimization of ultrasonic-assisted enzymatic hydrolysis to extract soluble substances from edible fungi by-products. Food and Bioprocess Technology, 16, 167–184. https://doi.org/10.1007/s11947-022-02930-0

Złotek, U., Mikulska, S., Nagajek, M., & Świeca, M. (2016). The effect of different solvents and number of extraction steps on the polyphenol content and antioxidant capacity of basil leaves (Ocimum basilicum L.) extracts. Saudi Journal of Biological Sciences, 23, 628–633. https://doi.org/10.1016/j.sjbs.2015.08.002

Funding

Open access funding provided by Università degli Studi di Perugia within the CRUI-CARE Agreement.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. All authors read and approved the final manuscript. Luciano Mangiapelo: investigation, data curation, formal analysis; Francesca Blasi: methodology, writing — review and editing; Federica Ianni: conceptualization, investigation, methodology, writing — original draft; Chiara Suvieri: investigation, formal analysis; Roccaldo Sardella: writing — review and editing; Claudia Volpi: investigation, writing — review and editing; Lina Cossignani: conceptualization, methodology, writing — review and editing, supervision.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mangiapelo, L., Blasi, F., Ianni, F. et al. Optimization of a Simple Analytical Workflow to Characterize the Phenolic Fraction from Grape Pomace. Food Bioprocess Technol (2023). https://doi.org/10.1007/s11947-023-03249-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11947-023-03249-0