Abstract

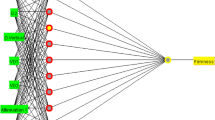

Plant-based food materials (PBFMs) such as fruits and vegetables contain various irregular cellular compartments. Like other engineering materials, the characterisation of micromechanical properties (MMPs) of PBFMs is intensely important for accurately estimating the functionality of dried food products. The application of a machine learning (ML)–based approach to characterise the MMPs is a promising idea. However, no intensive research in this regard has been attempted yet. Therefore, we proposed an ML-based modelling framework to characterise the MMPs of PBFMs during drying. A feed-forward artificial neural network (ANN) model with a backpropagation algorithm was developed and optimised with a genetic algorithm (GA)–based optimisation tool for characterising PBFMs, specifically carrots. Moreover, the accuracy of the ANN model was compared with a multiple nonlinear regression (MNLR) model. It was found that the developed network model agreed very well with the experimental data when predicting the elastic modulus, stiffness and hardness, with an accuracy of the goodness of fit (R2) values of 0.992, 0.993 and 0.802, respectively. It is expected that the developed model has incredible potential to characterise the MMPs of similar food products.

Similar content being viewed by others

Data Availability

All the weights and biases of the model and the MATLAB code developed by the author can be obtained from the corresponding author upon request.

References

Abadi, M., Barham, P., Chen, J., Chen, Z., Davis, A., Dean, J., & Isard, M. (2016). Tensorflow: A system for large-scale machine learning. In 12th USENIX symposium on operating systems design and implementation (OSDI 16) (pp. 265–283).

Aghbashlo, M., Kianmehr, M. H., Nazghelichi, T., & Rafiee, S. (2011). Optimization of an artificial neural network topology for predicting drying kinetics of carrot cubes using combined response surface and genetic algorithm. Drying Technology, 29(7), 770–779.

Attoh-Okine, N. O. (1999). Analysis of learning rate and momentum term in backpropagation neural network algorithm trained to predict pavement performance. Advances in Engineering Software, 30(4), 291–302.

Çakmak, G., & Yıldız, C. (2011). The prediction of seedy grape drying rate using a neural network method. Computers and Electronics in Agriculture, 75(1), 132–138.

Cárdenas-Pérez, S., Chanona-Pérez, J., Méndez-Méndez, J., Calderón-Domínguez, G., López-Santiago, R., & Arzate-Vázquez, I. (2016). Nanoindentation study on apple tissue and isolated cells by atomic force microscopy, image and fractal analysis. Innovative Food Science & Emerging Technologies, 34, 234–242.

Cárdenas-Pérez, S., Méndez-Méndez, J., Chanona-Pérez, J., Zdunek, A., Güemes-Vera, N., Calderón-Domínguez, G., & Rodríguez-González, F. (2017). Prediction of the nanomechanical properties of apple tissue during its ripening process from its firmness, color and microstructural parameters. Innovative Food Science & Emerging Technologies, 39, 79–87.

Clevert, D. -A., Unterthiner, T., & Hochreiter, S. (2015). Fast and accurate deep network learning by exponential linear units (elus). arXiv preprint. arXiv:1511.07289. Accessed 22 February 2016.

Cuq, B., Gonçalves, F., François Mas, J., Vareille, L., & Abecassis, J. (2003). Effects of moisture content and temperature of spaghetti on their mechanical properties. Journal of Food Engineering, 59(1), 51–60. https://doi.org/10.1016/S0260-8774(02)00430-2

Dintwa, E., Jancsók, P., Mebatsion, H., Verlinden, B., Verboven, P., Wang, C., & Nicolaï, B. (2011). A finite element model for mechanical deformation of single tomato suspension cells. Journal of Food Engineering, 103(3), 265–272.

Fathi, M., Mohebbi, M., & Razavi, S. M. A. (2011). Application of image analysis and artificial neural network to predict mass transfer kinetics and color changes of osmotically dehydrated kiwifruit. Food and Bioprocess Technology, 4(8), 1357–1366.

Fazaeli, M., Emam-Djomeh, Z., Omid, M., & Kalbasi-Ashtari, A. (2013). Prediction of the physicochemical properties of spray-dried black mulberry (Morus nigra) juice using artificial neural networks. Food and Bioprocess Technology, 6(2), 585–590.

Gulati, T., & Datta, A. K. (2015). Mechanistic understanding of case-hardening and texture development during drying of food materials. Journal of Food Engineering, 166, 119–138. https://doi.org/10.1016/j.jfoodeng.2015.05.031

Ho, Q. T., Carmeliet, J., Datta, A. K., Defraeye, T., Delele, M. A., Herremans, E., & van der Sman, R. (2013). Multiscale modeling in food engineering. Journal of Food Engineering, 114(3), 279–291.

Hobani, A. I., Thottam, A. M., & Ahmed, K. A. (2003). Development of a neural network classifier for date fruit varieties using some physical attributes. King Saud University-Agricultural Research Center.

Holland, J. H. (1992). Genetic Algorithms. Scientific American, 267(1), 66–73.

Hornik, K., Stinchcombe, M., & White, H. (1989). Multilayer feedforward networks are universal approximators. Neural Networks, 2(5), 359–366.

Jena, S., & Sahoo, A. (2013). ANN modeling for diffusivity of mushroom and vegetables using a fluidized bed dryer. Particuology, 11(5), 607–613.

Kaveh, M., Rasooli Sharabiani, V., Amiri Chayjan, R., Taghinezhad, E., Abbaspour-Gilandeh, Y., & Golpour, I. (2018). ANFIS and ANNs model for prediction of moisture diffusivity and specific energy consumption potato, garlic and cantaloupe drying under convective hot air dryer. Information Processing in Agriculture, 5(3), 372–387. https://doi.org/10.1016/j.inpa.2018.05.003

Keras, C. (2015). Theano-based deep learning libraryCode. https://github.com/fchollet. Documentation. http://keras.io. Accessed 22 February 2016.

Khan, M. I. H., Farrell, T., Nagy, S., & Karim, M. (2018). Fundamental understanding of cellular water transport process in bio-food material during drying. Scientific Reports, 8(1), 15191.

Khan, M. I. H., & Karim, M. (2017). Cellular water distribution, transport, and its investigation methods for plant-based food material. Food Research International, 99, 1–14.

Khan, M. I. H., Patel, N., Mahiuddin, M., & Karim, M. A. (2021). Characterisation of mechanical properties of food materials during drying using nanoindentation. Journal of Food Engineering, 291, 110306. https://doi.org/10.1016/j.jfoodeng.2020.110306

Khan, M. I. H., Sablani, S. S., Joardder, M. U. H., & Karim, M. A. (2020). Application of machine learning-based approach in food drying: Opportunities and challenges. Drying Technology, 40(6), 1051–1067. https://doi.org/10.1080/07373937.2020.1853152

Khan, M. I. H., Sablani, S. S., Nayak, R., & Gu, Y. (2022). Machine learning-based modeling in food processing applications: State of the art. Comprehensive Reviews in Food Science and Food Safety, 21(2), 1409–1438. https://doi.org/10.1111/1541-4337.12912

Khan, M. I. H., Wellard, R. M., Nagy, S. A., Joardder, M. U. H., & Karim, M. A. (2016). Investigation of bound and free water in plant-based food material using NMR T2 relaxometry. Innovative Food Science & Emerging Technologies, 38, 252–261. https://doi.org/10.1016/j.ifset.2016.10.015

Kotsiantis, S. B., Kanellopoulos, D., & Pintelas, P. E. (2006). Data preprocessing for supervised leaning. International Journal of Computer Science, 1(2), 111–117.

Kozioł, A., Cybulska, J., Pieczywek, P. M., & Zdunek, A. (2017). Changes of pectin nanostructure and cell wall stiffness induced in vitro by pectinase. Carbohydrate Polymers, 161, 197–207.

Krokida, M., & Maroulis, Z. (2000). Quality changes during drying of food materials. Drying Technology in Agriculture and Food Sciences, 4(2), 61–68.

Lewicki, P. P., & Jakubczyk, E. (2004). Effect of hot air temperature on mechanical properties of dried apples. Journal of Food Engineering, 64(3), 307–314. https://doi.org/10.1016/j.jfoodeng.2003.10.014

Mariani, V. C., Barbosa de Lima, A. G., & dos Santos Coelho, L. (2008). Apparent thermal diffusivity estimation of the banana during drying using inverse method. Journal of Food Engineering, 85(4), 569–579. https://doi.org/10.1016/j.jfoodeng.2007.08.018

Martynenko, A., & Janaszek, M. A. (2014). Texture changes during drying of apple slices. Drying Technology, 32(5), 567–577. https://doi.org/10.1080/07373937.2013.845573

Mohebbi, M., Fathi, M., & Shahidi, F. (2011). Genetic algorithm–artificial neural network modeling of moisture and oil content of pretreated fried mushroom. Food and Bioprocess Technology, 4(4), 603–609.

Pan, H., Yang, J., Shi, Y., & Li, T. (2015). BP neural network application model of predicting the apple hardness. Journal of Computational and Theoretical Nanoscience, 12(9), 2802–2807.

Pascua, Y., Koç, H., & Foegeding, E. A. (2013). Food structure: Roles of mechanical properties and oral processing in determining sensory texture of soft materials. Current Opinion in Colloid & Interface Science, 18(4), 324–333.

Rahman, M. S. (2001). Toward prediction of porosity in foods during drying: A brief review. Drying Technology, 19(1), 1–13.

Sablani, S. S., Baik, O. -D., & Marcotte, M. (2002). Neural networks for predicting thermal conductivity of bakery products. Journal of Food Engineering, 52(3), 299–304.

Sablani, S. S., & Rahman, M. S. (2003). Using neural networks to predict thermal conductivity of food as a function of moisture content, temperature and apparent porosity. Food Research International, 36(6), 617–623. https://doi.org/10.1016/S0963-9969(03)00012-7

Saeidirad, M. H., Rohani, A., & Zarifneshat, S. (2013). Predictions of viscoelastic behavior of pomegranate using artificial neural network and Maxwell model. Computers and Electronics in Agriculture, 98, 1–7.

Thussu, S., & Datta, A. K. (2012). Texture prediction during deep frying: A mechanistic approach. Journal of Food Engineering, 108(1), 111–121.

Vahedi Torshizi, M., Khojastehpour, M., Tabarsa, F., Ghorbanzadeh, A., & Akbarzadeh, A. (2020). Investigation of physical properties changes of kiwi fruit during different loadings, storage, and modeling with artificial neural network. International Journal of Fruit Science, 1–19.

Vasighi-Shojae, H., Gholami-Parashkouhi, M., Mohammadzamani, D., & Soheili, A. (2020). Predicting mechanical properties of golden delicious apple using ultrasound technique and artificial neural network. Food Analytical Methods, 13(3), 699–705.

Wang, C., Pritchard, J., & Thomas, C. (2006). Investigation of the mechanics of single tomato fruit cells. Journal of Texture Studies, 37(5), 597–606.

Wang, C., Wang, L., & Thomas, C. (2004). Modelling the mechanical properties of single suspension-cultured tomato cells. Annals of Botany, 93(4), 443–453.

Welsh, Z., Simpson, M. J., Khan, M. I. H., & Karim, M. A. (2018). Multiscale modeling for food drying: State of the art. Comprehensive Reviews in Food Science and Food Safety, 17(5), 1293–1308. https://doi.org/10.1111/1541-4337.12380

Xi, X., Kim, S. H., & Tittmann, B. (2015). Atomic force microscopy based nanoindentation study of onion abaxial epidermis walls in aqueous environment. Journal of Applied Physics, 117(2), 024703.

Xiaoyu, L., Xiaofang, W., Wei, W., & Jun, Z. (2007). Estimation of apple storage quality properties based on the mechanical properties with BP neural network. Transactions of the Chinese Society of Agricultural Engineering, 23(5), 150–153.

Zdunek, A., Kozioł, A., Cybulska, J., Lekka, M., & Pieczywek, P. M. (2016). The stiffening of the cell walls observed during physiological softening of pears. Planta, 243(2), 519–529.

Zdunek, A., & Kurenda, A. (2013). Determination of the elastic properties of tomato fruit cells with an atomic force microscope. Sensors, 13(9), 12175–12191.

Acknowledgements

The authors would like to thank the Energy & Drying Research Group at the Queensland University of Technology for supporting the drying experiments. We would also like to acknowledge Mr Nishane Patel and the Central Analytical Research Facility at the Queensland University of Technology for their support with the nano-indentation experimentation.

Funding

This research work was partially funded by the Australian Research Council (ARC) Discovery Grant (Grant ID: DP180103009).

Author information

Authors and Affiliations

Contributions

Md Imran H. Khan, conceptualization, methodology, data analysis, writing–review and editing; Duval longa, methodology, writing–review and editing; Shyam S. Sablani, methodology, writing–review and editing; YuanTong Gu, conceptualization; funding acquisition, resources supervision, writing–review and editing.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Khan, M.I.H., Longa, D., Sablani, S.S. et al. A Novel Machine Learning–Based Approach for Characterising the Micromechanical Properties of Food Material During Drying. Food Bioprocess Technol 16, 420–433 (2023). https://doi.org/10.1007/s11947-022-02945-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-022-02945-7