Abstract

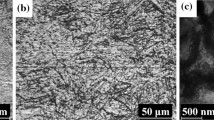

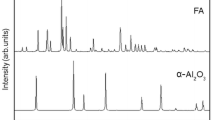

To correlate fluorapatite thin films’ morphology to their stability and bioactivity for temporary bioimplant applications, fluorapatite is ultrasonically spray-deposited on different substrates using chemical precursors. Mechanical agitation in phosphate-buffered saline solution is used to investigate the stability of the films aided with X-ray diffraction and electron microscopy for films’ morphology and thickness. For bioactivity, the cell adhesion to the fluorapatite thin films is evaluated by growing HaCaT cells on the film surface. The films deposited on titanium are pure and polycrystalline. Agitation in solution leads to a thickness reduction of 18.3%, and 30.5% for the films deposited on alumina. However, the persistence of the films after agitation suggests partial degradability. The improved stability of fluorapatite on titanium is attributed to the layer plus island-like morphology that offers a reduced contact area with the surrounding solution compared with the island-like morphology of fluorapatite on alumina. These different morphologies can be understood in the context of a smaller lattice mismatch between the substrate and the film which results in the layer plus island-like morphology. HaCaT cell adhesion on Ti-fluorapatite film surfaces is better than the titanium reference and alumina-fluorapatite suggesting its bioactivity and the promise of spray-deposited FAP for orthopedic applications.

Similar content being viewed by others

References

M. Iafisco, R. Bosco, S.C.G. Leeuwenburgh, J.J.J.P. van den Beucken, J.A. Jansen, M. Prat, and N. Roveri, Adv. Eng. Mater. 14, B13 https://doi.org/10.1002/adem.201180062 (2012).

K.A. Bhadang, and K.A. Gross, Biomaterials 25, 4935 https://doi.org/10.1016/j.biomaterials.2004.02.043 (2004).

K. de Groot, J.G.C. Wolke, and J.A. Jansen, Proc. Inst. Mech. Eng. Part H J. Eng. Med. 212, 137 https://doi.org/10.1243/0954411981533917 (1998).

S.V. Dorozhkin, World J. Methodol. 2, 1 https://doi.org/10.5662/wjm.v2.i1.1 (2012).

C.F. Dunne, B. Twomey, C. Kelly, J.C. Simpson, and K.T. Stanton, J. Mater. Sci.: Mater. Med. 26, 22 https://doi.org/10.1007/s10856-014-5347-5 (2015).

D. Haverty, S.A.M. Tofail, K.T. Stanton, and J.B. McMonagle, Phys. Rev. B 71, 094103 https://doi.org/10.1103/PhysRevB.71.094103 (2005).

S. Overgaard, M. Lind, K. Josephsen, A.B. Maunsbach, C. Bünger, and K. Søballe, J. Biomed. Mater. Res. 39, 141 (1998).

L. Shi, Y. Bai, J. Su, W. Ma, and R.-L. Jia, Int. J. Appl. Ceram. Technol. 14, 1088 https://doi.org/10.1111/ijac.12712 (2017).

H.O. Simila, N. Karpukhina, and R.G. Hill, Dent. Mater. 34, e1 https://doi.org/10.1016/j.dental.2017.10.005 (2018).

B. Ranjkesh, J. Chevallier, H. Salehi, F. Cuisinier, F. Isidor, and H. Løvschall, Acta Biomater. Odontol. Scand. 2, 68 https://doi.org/10.1080/23337931.2016.1178583 (2016).

Y. Huang, G. Song, X. Chang, Z. Wang, X. Zhang, S. Han, Z. Su, H. Yang, D. Yang, and X. Zhang, Int. J. Nanomed. 13, 2665 https://doi.org/10.2147/IJN.S162558 (2018).

Y. Bai, Y. Bai, J. Gao, W. Ma, J. Su, and R. Jia, J. Alloys Compd. 688, 657 https://doi.org/10.1016/j.jallcom.2016.07.006 (2016).

B.T. Bennett, J.P. Beck, K. Papangkorn, J.S. Colombo, K.N. Bachus, J. Agarwal, J.F. Shieh, and S. Jeyapalina, Mater. Sci. Eng. C 100, 665 https://doi.org/10.1016/j.msec.2019.03.025 (2019).

C.J. Pendegrass, A.E. Goodship, and G.W. Blunn, Biomaterials 27, 4183 https://doi.org/10.1016/j.biomaterials.2006.03.041 (2006).

D. Isackson, L.D. McGill, and K.N. Bachus, Med. Eng. Phys. 33, 418 https://doi.org/10.1016/j.medengphy.2010.11.007 (2011).

V. Mooney, S.A. Schwartz, A.M. Roth, and M.J. Gorniowsky, Ann. Biomed. Eng. 5, 34 https://doi.org/10.1007/BF02409337 (1977).

A. Alhilou, T. Do, L. Mizban, B.H. Clarkson, D.J. Wood, and M.G. Katsikogianni, ACS Omega 1, 264 https://doi.org/10.1021/acsomega.6b00080 (2016).

N. Guha-Chowdhury, A.G. Clark, and C.H. Sissons, Oral Microbiol. Immunol. 12, 91 https://doi.org/10.1111/j.1399-302X.1997.tb00623.x (1997).

R.E. Marquis, Can. J. Microbiol. 41, 955 https://doi.org/10.1139/m95-133 (1995).

N. Iqbal, M.R.A. Kadir, N.H.B. Mahmood, S. Iqbal, D. Almasi, F. Naghizadeh, H.R. Balaji, and T. Kamarul, Ceram. Int. 41, 6470 https://doi.org/10.1016/j.ceramint.2015.01.086 (2015).

S. Shadanbaz, and G.J. Dias, Acta Biomater. 8, 20 https://doi.org/10.1016/j.actbio.2011.10.016 (2012).

K. Jamuna-Thevi, M.J. Suleiman, and S.N. Sabri, Macromol. Symp. 371, 101 https://doi.org/10.1002/masy.201600048 (2017).

K. Jamuna-Thevi, N.M. Daud, M.R.A. Kadir, and H. Hermawan, Ceram. Int. 40, 1001 https://doi.org/10.1016/j.ceramint.2013.06.097 (2014).

C. Lindahl, W. Xia, J. Lausmaa, and H. Engqvist, Biomed. Mater. 7, 045018 https://doi.org/10.1088/1748-6041/7/4/045018 (2012).

N. Johari, M.H. Fathi, M.A. Golozar, E. Erfani, and A. Samadikuchaksaraei, J. Mater. Sci. Mater. Med. 23, 763 https://doi.org/10.1007/s10856-011-4528-8 (2012).

Y. Huang, X. Zhang, H. Qiao, M. Hao, H. Zhang, Z. Xu, X. Zhang, X. Pang, and H. Lin, Ceram. Int. 42, 1903 https://doi.org/10.1016/j.ceramint.2015.09.160 (2016).

V. Stanić, A.S. Radosavljević-Mihajlović, V. Živković-Radovanović, B. Nastasijević, M. Marinović-Cincović, J.P. Marković, and M.D. Budimir, Appl. Surf. Sci. 337, 72 https://doi.org/10.1016/j.apsusc.2015.02.065 (2015).

C.-S. Chien, Y.-S. Ko, T.-Y. Kuo, T.-Y. Liao, H.-C. Lin, T.-M. Lee, and T.-F. Hong, J. Med. Biolo. Eng. 35, 357 https://doi.org/10.1007/s40846-015-0048-1 (2015).

M. Ganjali, S. Mousavi, S. Nikzamir, P.B. Milan, and M. Mozafari, Mater. Technol. 37, 829 https://doi.org/10.1080/10667857.2021.1898716 (2022).

C.S. Chien, Z.Y. Liao, T.F. Hong, T.Y. Kuo, C.H. Chang, M.L. Yeh, and T.M. Lee, J. Med. Biolo. Eng. 34, 109 https://doi.org/10.5405/jmbe.1379 (2014).

J.K. Bibby, N.L. Bubb, D.J. Wood, and P.M. Mummery, J. Mater. Sci. Mater. Med. 16, 379 https://doi.org/10.1007/s10856-005-6975-6 (2005).

H.F. Ghorbel, A. Guidara, Y. Danlos, J. Bouaziz, and C. Coddet, Mater. Lett. 185, 268 https://doi.org/10.1016/j.matlet.2016.08.034 (2016).

H.F. Ghorbel, A. Guidara, Y. Danlos, J. Bouaziz, and C. Coddet, Mater. Sci. Eng. C 71, 1090 https://doi.org/10.1016/j.msec.2016.11.024 (2017).

M.H. Fathi, E.M. Zahrani, and A. Zomorodian, Mater. Lett. 63, 1195 https://doi.org/10.1016/j.matlet.2009.02.040 (2009).

O.A. Markelova, and S.Y. Pichkhidze, Glass Ceram. 77, 473 https://doi.org/10.1007/s10717-021-00335-7 (2021).

J.L. Ong, L.A. Harris, L.C. Lucas, W.R. Lacefield, and D. Rigney, J. Am. Ceram. Soc. 74, 2301 https://doi.org/10.1111/j.1151-2916.1991.tb08301.x (1991).

S. Loher, W.J. Stark, M. Maciejewski, A. Baiker, S.E. Pratsinis, D. Reichardt, F. Maspero, F. Krumeich, and D. Günther, Chem. Mater. 17, 36 https://doi.org/10.1021/cm048776c (2005).

I. Denry, and J.A. Holloway, Dent. Mater. 30, 112 https://doi.org/10.1016/j.dental.2013.10.009 (2014).

E. Ciliberto, and G. Spoto, Chem. Commun. https://doi.org/10.1039/A703318D (1997).

K. Cheng, W. Weng, H. Qu, P. Du, G. Shen, G. Han, J. Yang, and J.M.F. Ferreira, J. Biomed. Mater. Res. Part B Appl. Biomater. 69B, 33 https://doi.org/10.1002/jbm.b.20027 (2004).

L. Borkowski, A. Przekora, A. Belcarz, K. Palka, G. Jozefaciuk, T. Lübek, M. Jojczuk, A. Nogalski, and G. Ginalska, Mater. Sci. Eng. C 116, 111211 https://doi.org/10.1016/j.msec.2020.111211 (2020).

J. Ballarre, and S.M. Ceré, J. Sol-Gel Sci. Technol. 102, 96 https://doi.org/10.1007/s10971-021-05658-z (2022).

J.M. Ferreira, V. Rajendran, G. Simonelli, A.C.M. Silva, L.C.L. Santos, S. Mattedi, L.A.M. Pontes, I. Costa, J.L. Rossi, and M.A. Baker, Appl. Surf. Sci. 505, 144393 https://doi.org/10.1016/j.apsusc.2019.144393 (2020).

H. Chen, Z. Tang, J. Liu, K. Sun, S.R. Chang, M.C. Peters, J.F. Mansfield, A. Czajka-Jakubowska, and B.H. Clarkson, Adv. Mater. 18, 1846 https://doi.org/10.1002/adma.200502401 (2006).

R.T.A. Elghazel, J. Bouaziz, S. Charfi, H. Keskes, Scaffolds in tissue Eng. Mater., Technol. Clin. Appl., (IntechOpen, Croatia, 2017), pp 129–144.

F.F. Feagin, Calc. Tissue Res. 8, 154–164 https://doi.org/10.1007/bf02010132 (1971).

F.B. Ayed, J. Bouaziz, and K. Bouzouita, J. Eur. Ceram. Soc. 20, 1069 https://doi.org/10.1016/S0955-2219(99)00272-1 (2000).

D. Veilleux, N. Barthelemy, J.-C. Trombe, and M. Verelst, J. Mater. Sci. 36, 2245 (2001).

L.T. de Jonge, S.C.G. Leeuwenburgh, J.G.C. Wolke, and J.A. Jansen, Pharm. Res. 25, 2357 https://doi.org/10.1007/s11095-008-9617-0 (2008).

J.-M. Choi, H.-E. Kim, and I.-S. Lee, Biomaterials 21, 469 https://doi.org/10.1016/S0142-9612(99)00186-6 (2000).

Y. Hashimoto, M. Kawashima, R. Hatanaka, M. Kusunoki, H. Nishikawa, S. Hontsu, and M. Nakamura, J. Mater. Sci. Mater. Med. 18, 1457 https://doi.org/10.1007/s10856-006-0118-6 (2007).

P. Cheang, and K.A. Khor, Biomaterials 17, 537 https://doi.org/10.1016/0142-9612(96)82729-3 (1996).

L.G. Ellies, D.G.A. Nelson, and J.D.B. Featherstone, Biomaterials 13, 313 https://doi.org/10.1016/0142-9612(92)90055-S (1992).

J.S. Cho, J.-C. Lee, and S.-H. Rhee, J. Biomed. Mater. Res. Part B Appl. Biomater. 104, 422 https://doi.org/10.1002/jbm.b.33406 (2016).

M. Honda, Y. Kawanobe, K. Ishii, T. Konishi, M. Mizumoto, N. Kanzawa, M. Matsumoto, and M. Aizawa, Mater. Sci. Eng. C 33, 5008 https://doi.org/10.1016/j.msec.2013.08.026 (2013).

Ceramic Materials: Science and Engineering, ed. C.B. Carter and M.G. Norton (Springer New York, New York, NY, 2007), pp 400–411.

R. Azari, H.R. Rezaie, and A. Khavandi, Ceram. Int. 45, 17545 https://doi.org/10.1016/j.ceramint.2019.05.317 (2019).

M. Chambard, O. Marsan, C. Charvillat, D. Grossin, P. Fort, C. Rey, F. Gitzhofer, and G. Bertrand, Surf. Coat. Technol. 371, 68 https://doi.org/10.1016/j.surfcoat.2019.01.027 (2019).

S. Leeuwenburgh, J. Wolke, J. Schoonman, and J. Jansen, J. Biomed. Mater. Res. Part A 66A, 330 https://doi.org/10.1002/jbm.a.10590 (2003).

L. Müller, E. Conforto, D. Caillard, and F.A. Müller, Biomol. Eng. 24, 462 https://doi.org/10.1016/j.bioeng.2007.07.011 (2007).

P. Ducheyne, S. Radin, M. Heughebaert, and J.C. Heughebaert, Biomaterials 11, 244 https://doi.org/10.1016/0142-9612(90)90005-B (1990).

G. Bonel, J.-C. Heughebaert, M. Heughebaert, J.L. Lacout, and A. Lebugle, Ann. NY Acad. Sci. 523, 115 (1988).

S. Ban, and S. Maruno, J. Biomed. Mater. Res. 42, 387 (1998).

G. Berger, U. Ploska, and G. Willmann, Key Eng. Mater. 192–195, 111 (2000).

E. Park, R.A. Condrate, D.T. Hoelzer, and G.S. Fischman, J. Mater. Sci. Mater. Med. 9, 643 (1998).

D. Zaouk, Y. Zaatar, A. Khoury, C. Llinares, J.P. Charles, and J. Bechara, Microelectron. Eng. 51–52, 627 (2000).

A. Boyd, M. Akay, and B.J. Meenan, Surf. Interface Anal. 35, 188 https://doi.org/10.1002/sia.1512 (2003).

H. Monma, J. Mater. Sci. 29, 949 https://doi.org/10.1007/BF00351415 (1994).

T.K. Toivo and J.H. Mark, Aerosol processing of materials, (WILEY-VCH, New York, 1999), pp. 1,8,11–13,15,16,19–23,42,43,45–48,55,62–65,65,66,75–79,85–99,105,129–130,135,136,140,166,170,172,179–182,185–188,218,219,492,494,495,499, 500–504,506, 535,577, 602,603, 606–608, 610,654,655.

S. Che, O. Sakurai, K. Shinozaki, and N. Mizutani, J. Aerosol Sci 29, 271 https://doi.org/10.1016/S0021-8502(97)10012-X (1998).

J.M. Bian, X.M. Li, T.L. Chen, X.D. Gao, and W.D. Yu, Appl. Surf. Sci. 228, 297 https://doi.org/10.1016/j.apsusc.2004.01.020 (2004).

X. Fu, G. Wu, S. Song, Z. Song, X. Duo, and C. Lin, Appl. Surf. Sci. 148, 223 https://doi.org/10.1016/S0169-4332(99)00126-9 (1999).

O. Stryckmans, T. Segato, and P.H. Duvigneaud, Thin Solid Films 283, 17 https://doi.org/10.1016/0040-6090(95)08154-2 (1996).

S.Y. Wang, Z.P. Qiao, W. Wang, and Y.T. Qian, J. Alloys Compd. 305, 121 https://doi.org/10.1016/S0925-8388(00)00748-9 (2000).

S. Wang, W. Wang, J. Zuo, and Y. Qian, Mater. Chem. Phys. 68, 246 https://doi.org/10.1016/S0254-0584(00)00357-6 (2001).

S.Y. Wang, W. Wang, Q.C. Liu, M. Zhang, and Y.T. Qian, Solid State Ion. 133, 211 https://doi.org/10.1016/S0167-2738(00)00762-1 (2000).

D. Pavlopoulos, S. Al Khatiab, T.W. Button, and J.S. Abell, J. Phys. Conf. Ser. 97, 012098 (2008).

J.L. Boone, T.P. Van Doren, and A.K. Berry, Thin Solid Films 87, 259 https://doi.org/10.1016/0040-6090(82)90362-5 (1982).

V.M. Nikale, S.S. Shinde, C.H. Bhosale, and K.Y. Rajpure, J. Semicond. 32, 033001 https://doi.org/10.1088/1674-4926/32/3/033001 (2011).

S. Al Khateeb, In Metallurgy and Materials (University of Birmingahm: Birmingham, 2009).

D. Pavlopoulos, (University of Birmingham 2008).

O. Paschos, P. Choi, H. Efstathiadis, and P. Haldar, Thin Solid Films 516, 3796 https://doi.org/10.1016/j.tsf.2007.06.123 (2008).

S.E. Skrabalak, and K.S. Suslick, J. Am. Chem. Soc. 127, 9990 https://doi.org/10.1021/ja051654g (2005).

W.H. Suh, A.R. Jang, Y.H. Suh, and K.S. Suslick, Adv. Mater. 18, 1832 https://doi.org/10.1002/adma.200600222 (2006).

S. Al-Khateeb, D. Pavlopoulos, T.W. Button, and J.S. Abell, J. Supercond. Nov. Magn. 25, 1823 https://doi.org/10.1007/s10948-012-1560-y (2012).

S. Al-Khateeb, D. Pavlopoulos, T.W. Button, and J.S. Abell, J. Supercond. Nov. Magn. 26, 273 https://doi.org/10.1007/s10948-012-1740-9 (2013).

L. Zhang, L. Zhu, and A.V. Virkar, J. Electrochem. Soc. 163, F1358 https://doi.org/10.1149/2.0541613jes (2016).

L.X. Phua, F. Xu, Y.G. Ma, and C.K. Ong, Thin Solid Films 517, 5858 https://doi.org/10.1016/j.tsf.2009.03.065 (2009).

L. Vergnières, P. Odier, F. Weiss, C.E. Bruzek, and J.M. Saugrain, J. Eur. Ceram. Soc. 25, 2951 https://doi.org/10.1016/j.jeurceramsoc.2005.03.169 (2005).

Y.H. Lee, S.H. Im, J.-H. Lee, and S.I. Seok, Electrochim. Acta 56, 2087 https://doi.org/10.1016/j.electacta.2010.11.080 (2011).

S.A. Khateeb, Int. J. Mater. Res. 104, 301 https://doi.org/10.3139/146.110855 (2013).

D. Perednis, and L. Gauckler, J. Electroceram. 14, 103 https://doi.org/10.1007/s10832-005-0870-x (2005).

H. Liu, C. Song, Y. Tang, J. Zhang, and J. Zhang, Electrochim. Acta 52, 4532 https://doi.org/10.1016/j.electacta.2006.12.056 (2007).

S.A. Khateeb, A.G. Lind, R. Santos-Ortiz, N.D. Shepherd, and K.S. Jones, J. Electrochem. Soc. 162, A1667 https://doi.org/10.1149/2.0021509jes (2015).

L. Min, L. Danmin, Z. Meiling, Z. Yue, G. Xin, and L. Jinxia, Supercond. Sci. Technol. 17, 676 (2004).

S. Al Khateeb, T.W. Button, and J.S. Abell, Supercond. Sci. Technol. 23, 095001 https://doi.org/10.1088/0953-2048/23/9/095001 (2010).

D.S. Jung, T.H. Hwang, S.B. Park, and J.W. Choi, Nano Lett. 13, 2092 https://doi.org/10.1021/nl400437f (2013).

S. Al-Khateeb, and T.D. Sparks, J. Mater. Res. 34, 2456 https://doi.org/10.1557/jmr.2019.208 (2019).

S. Al Khateeb, and T.D. Sparks, J. Mater. Sci. 54, 4089 https://doi.org/10.1007/s10853-018-3055-0 (2019).

S. Al-khateeb, A.G. Lind, R. Santos-Ortiz, N.D. Shepherd, and K.S. Jones, J. Mater. Sci. 50, 5174 https://doi.org/10.1007/s10853-015-9062-5 (2015).

R. Santos-Ortiz, T. Rojhirunsakool, J.K. Jha, S. Al Khateeb, R. Banerjee, K.S. Jones, and N.D. Shepherd, Solid State Ion. 303, 103 https://doi.org/10.1016/j.ssi.2017.02.009 (2017).

R.R. Chamberlin, and J.S. Skarman, J. Electrochem. Soc. 113, 86 (1966).

S.D. Gunjal, Y.B. Khollam, S.R. Jadkar, T. Shripathi, V.G. Sathe, P.N. Shelke, M.G. Takwale, and K.C. Mohite, Sol. Energy 106, 56 https://doi.org/10.1016/j.solener.2013.11.029 (2014).

K.V. Krishna, V. Dutta, and K.S.R.K. Rao, Phys. Status Solidi A 198, 443 https://doi.org/10.1002/pssa.200306639 (2003).

S.D. Gunjal, Y.B. Khollam, R.R. Udawant, S.R. Jadkar, P.N. Shelke, J.V. Sali and K.C. Mohite, In Advanced Nanomaterials and Emerging Engineering Technologies (ICANMEET), 2013 International Conference on, (2013), pp 360–362.

H.B. Serreze, S. Lis, M.R. Squillante, R. Turcotte, M. Talbot and G. Entine, In Photovoltaic Specialists Conference, (Institute of Electrical and Electronics Engineers, Inc.: Florida, 1981), pp 1068–1072

P.S. Patil, Mater. Chem. Phys. 59, 185 https://doi.org/10.1016/S0254-0584(99)00049-8 (1999).

A. Gurav, T. Kodas, T. Pluym, and Y. Xiong, Aerosol Sci. Technol. 19, 411 https://doi.org/10.1080/02786829308959650 (1993).

M.J. Toivo TK, Aerosol processing of materials, (WILEY-VCH, New York, 1999), pp. 1–15, 492–493, 577, 1,8,11–13,15,16,19–23,42,43,45–48,55,62–65,65,66,75–79,85–99,105,129–130,135,136,140,166,170,172,179–182,185–188,218,219,492,494,495,499, 500–504,506, 535,577, 602,603, 606–608, 610,654,655.

S. Al Khateeb, B.T. Bennett, J.P. Beck, S. Jeyapalina, and T.D. Sparks, J. Mater. Res. 38, 2287 https://doi.org/10.1557/s43578-023-00961-7 (2023).

C. Chaïrat, J. Schott, E.H. Oelkers, J.-E. Lartigue, and N. Harouiya, GeoChim. CosmoChim. Acta 71, 5901 https://doi.org/10.1016/j.gca.2007.08.031 (2007).

J. Milan, Supercond. Sci. Technol. 8, 67 https://doi.org/10.1088/0953-2048/8/2/001 (1995).

G. Blandenet, M. Court, and Y. Lagarde, Thin Solid Films 77, 81 (1981).

L. Xu, X. Li, Y. Chen, and F. Xu, Appl. Surf. Sci. 257, 4031 https://doi.org/10.1016/j.apsusc.2010.11.170 (2011).

W.J. Zhang, Y.M. Chong, I. Bello, and S.T. Lee, J. Phys. D: Appl. Phys. 40, 6159 https://doi.org/10.1088/0022-3727/40/20/S03 (2007).

I. Vydrina, A. Malkov, K. Vashukova, I. Tyshkunova, L. Mayer, A. Faleva, S. Shestakov, E. Novozhilov, and D. Chukhchin, Carbohydr. Polym. Technol. Appl. 5, 100305 https://doi.org/10.1016/j.carpta.2023.100305 (2023).

M. Inoue, and I. Hirasawa, J. Cryst. Growth 380, 169 https://doi.org/10.1016/j.jcrysgro.2013.06.017 (2013).

K.L. Chopra, Thin film phenomena (McGraw-Hill, New York, London, 1969), p224.

M.A. Herman, W. Richter, and H. Sitter, Epitaxy: physical principles and technical implementation (Springer, Berlin, London, 2004), pp6–10.

C.V. Thompson, J. Floro, and H.I. Smith, J. Appl. Phys. 67, 4099 https://doi.org/10.1063/1.344969 (1990).

L.S. Donald, Thin-film deposition principles and practices (McGraw-ill, Newyork, 1995).

D. Krupa, J. Baszkiewicz, J. Zdunek, J. Smolik, Z. Słomka, and J.W. Sobczak, Surf. Coat. Technol. 205, 1743 https://doi.org/10.1016/j.surfcoat.2010.05.015 (2010).

D.V. Vasudev, J.L. Ricci, C. Sabatino, P. Li, and J.R. Parsons, J. Biomed. Mater. Res. Part A 69, 629 https://doi.org/10.1002/jbm.a.30028 (2004).

F. Romero-Gavilán, A. Cerqueira, I. García-Arnáez, M. Azkargorta, F. Elortza, M. Gurruchaga, I. Goñi, and J. Suay, J. Biomed. Mater. Res. Part A 111, 45 https://doi.org/10.1002/jbm.a.37444 (2023).

Acknowledgements

This project was supported by the Department of Defense CDMRP PRORP (award number W81XWH-15-1-0682), USA. This work has been conducted during the sabbatical leave granted to Dr. Shadi Al Khateeb from Al-Balqa Applied University (BAU) during the academic year 2017–2018.

Funding

Congressionally Directed Medical Research Programs, W81XWH-15-1-0682, Sujee Jeyapalina.

Author information

Authors and Affiliations

Contributions

SAK: Conceptualization, Methodology, Validation, Formal analysis, Investigation, Writing—Original Draft, Writing—Review & editing. BTB: Methodology, Investigation. JPB: Validation. SJ: Resources, Funding acquisition. TDS: Conceptualization, Validation, Resources, Writing—Review & editing, Funding acquisition.

Corresponding authors

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Al Khateeb, S., Bennett, B.T., Beck, J.P. et al. Morphological Evolution Effect on the Performance of Spray Pyrolysis-Based Synthesis of Fluorapatite Thin Films for Bioimplant Applications. JOM 75, 3332–3344 (2023). https://doi.org/10.1007/s11837-023-05892-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-05892-6