Abstract

Growing applications of additive manufacturing (AM) have now been adopted for metal castings via indirect hybrid AM, i.e., 3D sand printing (3DSP). A comprehensive study on the thermo-physical properties of 3DSP molds based on 3DSP processing conditions and their effects on materials and mechanical properties of resulting aluminum castings is presented. The effect of furan binder content (i.e., 1–3%) on as-printed 3DSP molds is evaluated to determine changes in dimensional accuracy, density (helium pycnometry), actual binder content (loss on ignition) and mechanical strength (three-point bending and tensile testing) and thermal properties (transient plane source technique and casting runs). Pore network characterization via mercury intrusion porosimetry does not reveal any significant differences in the morphology of pore structures due to varying binder concentrations. However, bulk permeability is reduced with increasing binder content. Thermal analysis shows a reduction in conductivity and heat capacity due to binder degradation. Findings from this study will enable the optimum selection of binder content for functional grading of 3DSP molds/cores for adequate degassing and mechanical strength, which is ready for adoption by both foundries and 3DSP service providers.

Similar content being viewed by others

References

Grand View Research, Aluminum Casting Market Worth $86.5 Billion by 2025 (Grand View Research, 2019). https://www.grandviewresearch.com/press-release/global-aluminum-casting-market. Accessed 21 May 2019.

E.S. Almaghariz, B.P. Conner, L. Lenner, R. Gullapalli, G.P. Manogharan, B. Lamoncha, and M. Fang, Int. J. Metalcast. 10, 240 (2016).

D. Strong, I. Sirichakwal, G.P. Manogharan, and T. Wakefield, Rapid Prototyp. J. 23, 577 (2017).

E.S. Almaghariz, MSc Thesis, Youngstown State University (2015).

J. Wang, S.R. Sama, and G. Manogharan, Int. J Metalcast. 13, 2 (2019).

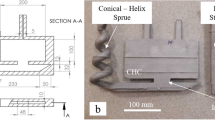

S.R. Sama, J. Wang, and G. Manogharan, J. Manuf. Process. 34, 765 (2018).

S.R. Sama, T. Badamo, P. Lynch, and G. Manogharan, Addit. Manuf. 25, 563 (2019).

C. Weller, R. Kleer, and F.T. Piller, Int. J. Prod. Econ. 164, 43 (2015).

D. Snelling, Q. Li, N. Meisel, C.B. Williams, R.C. Batra, and A.P. Druschitz, Adv. Eng. Mater. 17, 923 (2015).

P. Hackney and R. Wooldridge, Procedia Manuf. 11, 457 (2017).

B. Rooks, Assem. Autom. 22, 40 (2002).

A. Bernard, J.C. Delplace, N. Perry, and S. Gabriel, Rapid Prototyp. J. 9, 327 (2012).

S. Mitra, A. Rodríguez de Castro, and M. El Mansori, Int. J. Adv. Manuf. Technol. 97, 1241 (2018).

K. Nyembwe, M. Mashila, P.J.M. van Tonder, D.J. de Beer, and E. Gonya, S. Afr. J. Ind. Eng. 27, 136 (2016).

T. Sivarupan, M. El Mansori, K. Daly, M.N. Mavrogordato, and F. Pierron, Rapid Prototyp. J. 25, 404 (2019).

A.V. Adedayo, J. Braz. Soc. Mech. Sci. Eng. 32, 171 (2010).

A.V. Adedayo, B. Aremo, and P. Si, J. Miner. Mater. Charact. Eng. 10, 387 (2011).

C. Saikaew and S. Wiengwiset, Appl. Clay Sci. 67–68, 26 (2012).

C.Y. Deng, J.W. Kang, H.L. Shangguan, T. Huang, X.P. Zhang, Y.Y. Hu, and T. Huang, China Foundry 15, 37 (2018).

C. Deng, J. Kang, H. Shangguan, Y. Hu, T. Huan, and Z. Liu, J. Mater. Process. Technol. 255, 516 (2018).

H. Shangguan, J. Kang, C. Deng, J. Yi, Y. Hu, and T. Huang, Int. J. Adv. Manuf. Technol. 96, 2175 (2018).

P.M. Hackney and R. Wooldridge, Rapid Prototyp. J. 23, 7 (2017).

S. Mitra, A. Rodríguez de Castro, and M. El Mansori, J. Manuf. Process. 42, 202 (2019).

AFS, Procedure 5100-00-S, Mold Core Test Handbook, 3rd ed. (Shaumburg-IL: AFS, 2001).

A. Gardziella, L. Pilato, and A. Knop, Phenolic Resins—Chemistry, Applications, Standardization, Safety and Ecology, 2nd ed. (Berlin: Springer, 2000).

I. Chatzis and F.A.L. Dullien, Int. Chem. Eng. 25, 47 (1985).

H.H. Yuan and B.F. Swanson, SPE Form. Eval. 4, 17 (1989).

M.M. Labani, R. Rezaee, A. Saeedi, and A. Al Hinai, J. Pet. Sci. Eng. 112, 7 (2013).

R.A. Cook and K.C. Hover, Cem. Concr. Res. 29, 933 (1999).

A.B. Abell, K.L. Willis, and D.A. Lange, J. Colloid Interface Sci. 211, 39 (1999).

C. Gallé, Cem. Concr. Res. 31, 1467 (2001).

A.B. Selkirk and D. Ganderton, J. Pharm. Pharmacol. 22, 79S (1970).

F. Carli and A. Motta, J. Pharm. Sci. 73, 197 (1984).

A.M. Juppo, Int. J. Pharm. 129, 1 (1996).

P.A. Webb, An Introduction to the Physical Characterization of Materials by Mercury Intrusion Porosimetry with Emphasis on Reduction and Presentation of Experimental Data (Micromeritics Inst Corp, 2001), https://www.micromeritics.com/pdf/app_articles/mercury_paper.pdf. Accessed 21 May 2019.

P.K. Krajewski, J.S. Suchy, G. Piwowarski, and W.K. Krajewski, Arch. Foundry Eng. 15, 47 (2015).

P.K. Krajewski, G. Piwowarski, and J.S. Suchy, Arch. Foundry Eng. 14, 67 (2014).

Y. Xu and D. Chung, Cem. Concr. Res. 30, 59 (2000).

T.J. Williams, MSc Thesis, University of Iowa, 2016.

T.J. Williams, R.A. Hardin, and C. Beckermann, in Proceedings of the 68th SFSA Technical and Opererating Conference, Paper No. 4.6 (2014).

M.T. Sun and C.H. Chang, J. Heat Transf. 129, 1119 (2007).

R. Coquard, E. Coment, G. Flasquin, and D. Baillis, Int. J. Therm. Sci. 65, 242 (2013).

S.E. Gustafsson, Rev. Sci. Instrum. 62, 797 (1991).

T. Log and S.E. Gustafsson, Fire Mater. 19, 43 (1995).

P. Jelinek and T. Elbel, Arch. Foundry Eng. 10, 77 (2010).

N. Chvorinov, Proc. Inst. Br. Foundrym 32, 229 (1938).

P. Beeley, Foundry Technology, 2nd ed. (Oxford: Butterworth-Heinemann, 2001).

S. Atre, K. Kate, and J. Porter, in European Congress and Exhibition on Powder Metallurgy. European PM Conference Proceedings (2016), p. 1.

D. Hong, D.T. Chou, O.I. Velikokhatnyi, A. Roy, B. Lee, I. Swink, I. Issaev, H.A. Kuhn, and P.N. Kumta, Acta Biomater. 45, 375 (2016).

B. Yun and C. Williams, Rapid Prototyp. J. 21, 177 (2015).

AFS, Procedure 3301-08-S, Mold Core Test Handbook, 3rd ed. (Shaumburg-IL: AFS, 2001).

B. Primkulov, J. Chalaturnyk, R. Chalaturnyk, and G. Zambrano Narvaez, 3D Print Addit. Manuf. 4, 149 (2017).

AFS, Procedure 5224-13-S, Mold Core Test Handbook, 3rd ed. (Shaumburg-IL: AFS, 2001).

VDG, Biegefestigkeit von warmhärtenden, kunstharzgebundenen feuchten Formstoffen (Düsseldorf, 1999).

ASTM E290-09, Standard Test Methods for Bend Testing of Material for Ductility (West Choshohocken: ASTM E290-09, 2009).

E.W. Washburn, Phys. Rev. 17, 273 (1921).

G.F. Vander Voort, Metallography—Principles and Practice (Materials Park: ASM International, 1999).

P. Sirivimonpa and N. Osothsilp, Key Eng. Mater. 765, 255 (2018).

H. Khandelwal and B. Ravi, Mater. Manuf. Process. 30, 1465 (2015).

N. Coniglio, T. Sivarupan, and M. El Mansori, Int. J. Adv. Manuf. Technol. 94, 2175 (2018).

K.J. Hodder and R.J. Chalaturnyk, Addit. Manuf. 28, 649 (2019).

S. Tamas and B. Dermot, in Solid Free Fabrication Symposium Proceedings (2007), p. 470.

D. Snelling, C.B. Williams, and A.P. Druschitz, in Solid Free Fabrication Symposium Proceedings (2014), p. 197.

O. Tsumura, H. Narita, D. Tomigashi, M. Okino, and K. Miyauchi, Jpn. Foundry Eng. Soc. 81, 77 (2009).

H. Khandelwal and B. Ravi, J. Manuf. Process. 22, 127 (2016).

EnvisionTEC, “Viridis3D” (EnvisionTEC), https://envisiontec.com/3d-printers/robotic-additive-manufacturing/. Accessed 24 Sept 2019.

J. Thole and C. Beckermann, Int. J. Metalcast. 4, 7 (2010).

B.J. Stauder, H. Kerber, and P. Schumacher, J. Mater. Process. Technol. 237, 188 (2016).

K. Meyer and P. Klobes, Fresenius J. Anal. Chem. 363, 174 (1999).

C. Gau and R. Viskanta, J. Heat Transf. 108, 174 (1986).

L.J. Williams and H. Abdi, Fisher’s least significant difference (LSD) test.Encyclopedia of Research Design, ed. N. Salkind (Thousand Oaks: Sage, 2010),

D. Stefanescu and R. Ruxanda, Solidification structure of aluminum alloys, in ASM Handbook Volume 9—Metallography and Microstructures (Novelty, ASM International, 2004), p. 107.

D. Stefanescu, Science and Engineering of Casting Solidification (New York: Springer, 2002).

Acknowledgements

The authors thank Dr. Robert Voigt for his expert advice and Chris Anderson and Travis Richner for helping with casting trials. This work was partially funded by a PA Manufacturing Fellows Grant from the PA Department of Community and Economic Development.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Martinez, D., Bate, C. & Manogharan, G. Towards Functionally Graded Sand Molds for Metal Casting: Engineering Thermo-mechanical Properties Using 3D Sand Printing. JOM 72, 1340–1354 (2020). https://doi.org/10.1007/s11837-019-03975-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03975-x