Abstract

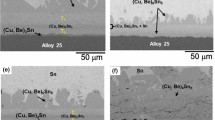

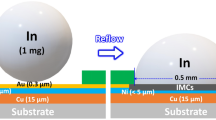

The liquid/solid interfacial reactions of Sn, Sn-(3.0 wt.% to 0.5 wt.%)Cu (SAC), and Sn-9.0 wt.%Zn (SZ) solders with Ni-xPd-yCo substrates at 240°C, 270°C, and 300°C for 0.5 h to 5 h have been investigated. The Ni-xPd-yCo alloys were prepared with x = 0.5 wt.% and 1.5 wt.% and y = 0.5 wt.%, 1.5 wt.%, and 3.0 wt.%. The intermetallic compound (IMC) Ni3Sn4 formed in the Sn/Ni-xPd-yCo reaction couples at 240°C, 270°C, and 300°C. Although (Cu,Ni)6Sn5 and (Ni,Cu)3Sn4 phases appeared at the interface of the SAC/Ni-xPd-yCo couples after 0.5 h to 2 h at 240°C, only (Ni,Cu)3Sn4 phase formed after 5 h at 240°C or 0.5 h to 5 h at 270°C or 300°C in the SAC/Ni-xPd-yCo systems. The SZ/Ni-xPd-yCo interfacial reactions at three different temperatures formed the Ni5Zn21 phase, but when the reaction time was extended to 5 h, Ni5Zn21, Sn, and δ phases were also observed. The thickness of the IMCs was measured and used to calculate the reaction rate constant and activation energy. The interfacial reactions between the lead-free solders (Sn, SAC, and SZ) and Ni-xPd-yCo substrates were determined to be diffusion controlled.

Similar content being viewed by others

References

Y.W. Wang, Y.W. Lin, C.T. Tu, and C.R. Kao, J. Alloys Compd. 478, 121 (2009).

H. Nishikawa, A. Komatsu, and T. Takemoto, Mater. Trans. 49, 1518 (2008).

D.H. Kim, M.G. Cho, S.-K. Seo, and H.M. Lee, J. Electron. Mater. 38, 39 (2009).

G. Ghosh, Acta Mater. 48, 3719 (2000).

H. Nishikawa, A. Komatsu, and T. Takemoto, J. Electron. Mater. 36, 1137 (2007).

C.-F. Tseng, T.-K. Lee, G. Ramakrishna, K.-C. Liu, and J.-G. Duh, Mater. Lett. 65, 3216 (2011).

Y.-H. Chao, S.-W. Chen, C.-H. Chang, and C.-C. Chen, Metall. Mater. Trans. A 39, 477 (2008).

Y.-T. Chen, Y.-T. Chan, and C.-C. Chen, J. Alloys Compd. 507, 419 (2010).

H.-F. Lin, Y.-C. Chang, and C.-C. Chen, J. Electron. Mater. 43, 3333 (2014).

P. Nash and A. Nash, Bull. Alloy Phase Diagr. 6, 350 (1985).

S.-W. Chen, C.-M. Chen, and W.-C. Liu, J. Electron. Mater. 27, 1193 (1998).

C.M. Chen and S.W. Chen, Acta Mater. 50, 2461 (2002).

Y.-S. Li, Master’s Degree, National Taiwan University of Science and Technology (2014).

C.-Y. Ho and J.-G. Duh, Mater. Lett. 92, 278 (2013).

C.-H. Lin, S.-W. Chen, and C.-H. Wang, J. Electron. Mater. 31, 907 (2002).

C.E. Ho, R.Y. Tsai, Y.L. Lin, and C.R. Kao, J. Electron. Mater. 31, 584 (2002).

C.E. Ho, Y.W. Lin, S.C. Yang, C.R. Kao, and D.S. Jiang, J. Electron. Mater. 35, 1017 (2006).

S.-W. Chen, C.-M. Hsu, C.-Y. Chou, and C.-W. Hsu, Prog. Nat. Sci. Mater. Int. 21, 386 (2011).

B.F. Dyson, T.R. Anthony, and D. Turnbull, J. Appl. Phys. 38, 3408 (1967).

C.-H. Wang, H.-H. Chen, and P.-Y. Li, Mater. Chem. Phys. 136, 325 (2012).

Acknowledgements

The authors acknowledge financial support from the Ministry of Science and Technology, Taiwan, R.O.C. (Grant No. MOST 104-2628-E-011-001-MY3) and the Applied Research Center for Thin-Film Metallic Glass from The Featured Areas Research Center Program within the framework of the Higher Education Sprout Project by the Ministry of Education (MOE) in Taiwan. The authors are also grateful for help from Mr. S. C. Laiw, who works at National Taiwan University of Science and Technology, for SEM–EDS operation and Mr. C. Y. Kao, who works at National Taiwan University, and Mrs. Tsai, who works at National Tsing Hua University, for carrying out the EPMA analysis.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yen, YW., Hsiao, HM., Chen, KJ. et al. Interfacial Reactions Between Lead-Free Solders and Ni-Pd-Co Alloys. JOM 71, 3031–3040 (2019). https://doi.org/10.1007/s11837-019-03625-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03625-2