Abstract

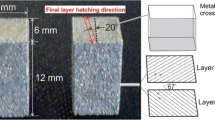

Solidification during selective laser melting (SLM) needs to be better understood. In this work, track formation and how it affects grain growth during SLM of Co-29Cr-6Mo alloy over the laser power range of 180–360 W with other parameters kept constant have been studied. The track shape observed has suggested a conduction mode during SLM consistent with the calculated normalized enthalpy that indicates no significant vaporisation to form keyholes. Increasing the laser power led to increases in the track size with track boundaries remained largely circular arc-shaped. Grain growth direction and size are shown to be affected by track size. Measured values of track size have enabled the estimation of growth rate and, coupled with the measurement of cell size, the thermal gradient has been calculated. These data will be discussed in relation to modes of solidification.

Similar content being viewed by others

References

T. DebRoy, H.L. Wei, J.S. Zuback, T. Mukherjee, J.W. Elmer, J.O. Milewski, A.M. Beese, A. Wilson-Heid, A. De, and W. Zhang, Prog. Mater Sci. 92, 112 (2018).

S.S. Babu, Scr. Mater. 135, 97 (2017).

Y. Kok, X.P. Tan, P. Wang, M.L.S. Nai, N.H. Loh, E. Liu, and S.B. Tor, Mater. Des. 139, 565 (2018).

D. Zhang, S. Sun, D. Qiu, M.A. Gibson, M.S. Dargusch, M. Brandt, M. Qian, and M. Easton, Adv. Eng. Mater. 20, 1700952 (2018).

Z.W. Chen, M.A.L. Phan, and K. Darvish, J. Mater. Sci. 52, 7415 (2017).

K. Darvish, Z.W. Chen, M.A.L. Phan, and T. Pasang, Mater. Charact. 135, 183 (2018).

K. Darvish, Z.W. Chen, and T. Pasang, Mater. Design 112, 357 (2016).

A. Kaplan, The Theory of Laser Materials Processing, ed. J. Dowden (Dordrecht: Springer, 2009), p. 71.

D.B. Hann, J. Iammi, and J. Folkes, J. Phys. D 44, 445401 (2011).

W.E. King, H.D. Barth, V.M. Castillo, G.F. Gallegos, J.W. Gibbs, D.E. Hahn, G. Kamath, and A.M. Rubenchik, J. Mater. Process. Technol. 214, 2915 (2014).

W. Kurz and D.J. Fisher, Fundamentals of Solidification, 4th ed. (Stafa: Trans Tech Publications Ltd, 1998).

K. Harris and S. Sikkenga, In: Proceedings of the 24th BICTA Investment Casting Conference: New Horizons and Process Capabilities, British Investment Casting Trade Association, 1999, p. 8.

M.J. Bermingham, S.D. McDonald, D.H. StJohn, and M.S. Dargusch, J. Mater. Res. 26, 951 (2011).

R.R. Dehoff, M.M. Kirka, W.J. Sames, H. Bilheux, A.S. Tremsin, L.E. Lowe, and S.S. Babu, Mater. Sci. Technol. 31, 931 (2015).

P.A. Kobryn and S.L. Semiatin, J. Mater. Process. Technol. 135, 330 (2003).

Acknowledgements

Teresa Guraya wishes to thank Erasmus Mundus Partnerships “PANTHER” Programme for financially supporting her to conduct additive manufacturing research at Auckland University of Technology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Z.W., Guraya, T., Darvish, K. et al. Solidification During Selective Laser Melting of Co-29Cr-6Mo Alloy. JOM 71, 691–696 (2019). https://doi.org/10.1007/s11837-018-3264-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-3264-7