Abstract

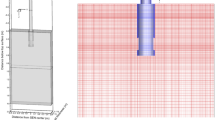

A coupled three-dimensional model, including Large Eddy Simulation model, Lagrangian Discrete Phase Model and VOF multiphase model was developed to investigate the transient two-phase flow and bubble distribution in continuous casting strand. A two-way coupling model including the effect of the drag force, lift force, virtual mass force and pressure gradient force was adopted. The lift force was added via user defined function. A Rosin–Rammler bubble size distribution base on the water model was employed. The results show that the effect of the lift force cannot be ignored during the calculation of the steel and argon gas two-phase flow. Only the bubbles smaller than 2 mm would be brought to near the narrow face. With the increase of the argon flow rate, the transformation of the flow pattern from the double roll to complex flow and single roll was successfully predicted.

Similar content being viewed by others

References

L. Zhang, S. Yang, K. Cai, J. Li, X. Wan, and B.G. Thomas, Metall. Mater. Trans. B 38, 63 (2007).

R. Sánchez-Perez, R.D. Morales, M. Díaz-Cruz, O. Olivares-Xometl, and J. Palafox-Ramos, ISIJ Int. 43, 637 (2003).

Q. Yuan, B. Zhao, S.P. Vanka, and B.G. Thomas, Steel Res. Int. 76, 33 (2005).

B.G. Thomas and L. Zhang, ISIJ Int. 41, 1181 (2001).

B.G. Thomas, Steel Res. Int. (2018). https://doi.org/10.1002/srin.201700312.

E. Olmos, C. Gentric, C. Vial, G. Wild, and N. Midoux, Chem. Eng. Sci. 56, 6359 (2001).

M.E. Díaz, A. Iranzo, D. Cuadra, R. Barbero, F.J. Montes, and M.A. Galán, Chem. Eng. J. 139, 363 (2008).

H.A. Jakobsen, Chem. Eng. Sci. 56, 1049 (2001).

M.V. Tabib, S.A. Roy, and J.B. Joshi, Chem. Eng. J. 139, 589 (2008).

D. Zhang, N.G. Deen, and J.A.M. Kuipers, Chem. Eng. Sci. 61, 7593 (2006).

V. Singh, S.K. Dash, J.S. Sunitha, S.K. Ajmani, and A.K. Das, ISIJ Int. 46, 210 (2006).

Z. Liu, B. Li, M. Jiang, and F. Tsukihashi, ISIJ Int. 53, 484 (2013).

Z. Liu, B. Li, M. Jiang, L. Zhang, and G. Xu, Acta Metall. Sin. 49, 513 (2013).

Z. Liu and B. Li, Metall. Mater. Trans. B 48, 1833 (2017).

H. Bai and B.G. Thomas, Metall. Mater. Trans. B 32, 707 (2001).

H. Bai and B.G. Thomas, Metall. Mater. Trans. B 32, 269 (2001).

H. Bai and B.G. Thomas, Metall. Mater. Trans. B 32, 253 (2001).

B.G. Thomas, L.J. Mika, and F.M. Najjar, Metall. Mater. Trans. B 21, 387 (1990).

T. Toh, H. Hasegawa, and H. Harada, ISIJ Int. 41, 1245 (2001).

C. Pfeiler, M. Wu, and A. Ludwig, Mater. Sci. Eng., A 413–414, 115 (2005).

K. Jin, B.G. Thomas, and X. Ruan, Metall. Mater. Trans. B 47, 548 (2016).

C. Liu, Z. Luo, T. Zhang, S. Deng, N. Wang, and Z. Zou, J. Iron. Steel Res. Int. 21, 403 (2014).

Q. Cao and L. Nastac, Metall. Mater. Trans. B 49, 1388 (2018).

S.W.P. Cloete, J.J. Eksteen, and S.M. Bradshaw, Prog. Comput. Fluid Dyn. 9, 345 (2009).

P.E. Ramirez Lopez, P.N. Jalali, J. Björkvall, U. Sjöström, and C. Nilsson, ISIJ Int. 54, 342 (2014).

W. Chen and L. Zhang, ICS 2018, Venice, Italy (2018).

W. Chen and L. Zhang, STEELSIM 2017 (China: Qingdao, 2017).

D. Shangguan, S. Ahuja, and D.M. Stefanescu, Metall. Mater. Trans. A 23, 669 (1992).

W. Chen, Y. Ren, and L. Zhang, Steel Res. Int. (2018). https://doi.org/10.1002/srin.201800287.

M.M. Salazar-Campoy, R.D. Morales, A. Nájera-Bastida, V. Cedillo-Hernández, and J.C. Delgado-Pureco, Metall. Mater. Trans. B 48, 1376 (2017).

P.S. Srinivas, A. Singh, J.M. Korath, and A.K. Jana, ISIJ Int. 57, 1553 (2017).

Z. Liu, B. Li, F. Qi, and S.C.P. Cheung, Powder Technol. 319, 139 (2017).

Acknowledgements

The authors are grateful for support from the National Science Foundation China (Grant Nos. 51725402 and 51504020), the Fundamental Research Funds for the Central Universities (Grant Nos. FRF-TP-15-001C2 and 2015021642901), Beijing Key Laboratory of Green Recycling and Extraction of Metals (GREM) and the High Quality steel Consortium (HQSC) at the School of Metallurgical and Ecological Engineering at University of Science and Technology Beijing (USTB), China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, W., Ren, Y., Zhang, L. et al. Numerical Simulation of Steel and Argon Gas Two-Phase Flow in Continuous Casting Using LES + VOF + DPM Model. JOM 71, 1158–1168 (2019). https://doi.org/10.1007/s11837-018-3255-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-3255-8