Abstract

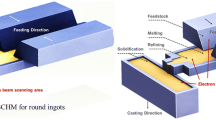

The Electron beam cold hearth remelting (EBCHR) process has emerged as a key process in producing overlength TC4 round ingots. However, the quality of the ingots suffer from inhomogeneous composition segregation which is induced by improper operations. In the present study, a numerical model verified with experimental data from the literature was employed to investigate the finer details of EBCHM process. In order to track temperature evolution on the mold surface, heating by an approximating beam-pattern, user-defined function compiled with C code was added to the calculation. In addition, the evolution of the solid–liquid interface and melt-flow during EBCHM were also investigated under different operation conditions. The recommended pool morphology was found when the inlet velocity was 0.0295 m/s, the temperature of the inlet was maintained at 2173 K, and the mold surface was maintained at 1973 K. In those conditions, stirring inside the pool was strengthened to homogenize the composition, which may optimize the quality of the ingots.

Similar content being viewed by others

References

X. Zhao, C. Reilly, L. Yao, D.M. Maijer, S.L. Cockcroft, and J. Zhu, Appl. Math. Model. 38, 3607 (2014).

H.R. Harker, Vacuum 41, 2154 (1990).

A. Mitchell, Mater. Sci. Eng. A 263, 217 (1999).

J.R. Wood, JOM 54, 56 (2002).

R.E. Shuster, Modeling of Aluminum Evaporation During Electron Beam Cold Hearth Melting of Titanium Alloy Ingots, Masters thesis, The University of British Columbia (2013).

J.P. Bellot, D. Ablitzer, and E. Hess, Metal. Mater. Trans. B 31, 845 (2000).

S.V. Akhonin, N.P. Trigub, V.N. Zamkov, and S.L. Semiatin, Metal. Mater. Trans. B 34, 447 (2003).

A. Powell, J. Wan den Avyle, B. Damkroger, J. Szekely, and U. Pal, Metal. Mater. Trans. B 28, 1227 (1997).

Q. Liu, X. Li, and Y. Jiang, Vacuum 141, 1 (2017).

Q. Liu, X. Li, and Y. Jiang, J. Mater. Res. 32, 1 (2017).

R. Shuster, C. Reilly, D.M. Maijer, and S.L. Cockcroft, IOP Conf. Ser. Mater. Sci. Eng. 33, 1 (2012).

ANSYS Inc. ANSYS Fluent Theory Guide (Release 15.0, 2013). http://www.ansys.com. Accessed Nov 2013.

Z. Zhang, Modeling of Al Evaporation and Marangoni Flow in Electron Beam Button Melting of Ti-6Al-4V, Masters thesis, The University of British Columbia (2013).

K. Vutova, E. Koleva, and G. Mladenov, Int. Rev. Mech. Eng. 5, 257 (2009).

E. Koleva, K. Vutova, and G. Mladenov, Vacuum 62, 189 (2001).

Acknowledgements

The authors are grateful for the financial support of the National Key R&D Program of China (2016YFB0301200). In addition, the comments from Dr. Xiangming Li are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, L., Huang, H., Zhang, Y. et al. Numerical Modeling of EBCHM for Large-Scale TC4 Alloy Round Ingots. JOM 70, 2934–2942 (2018). https://doi.org/10.1007/s11837-018-3048-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-3048-0