Abstract

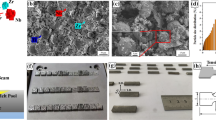

Rectangular Ti6Al4V extralow interstitials (ELI) samples were manufactured by laser powder bed fusion (LPBF) in vertical and horizontal orientations relative to the build platform and subjected to various heat treatments. Detailed analyses of porosity, microstructure, residual stress, tensile properties, fatigue, and fracture surfaces were performed based on x-ray micro-computed tomography, scanning electron microscopy, and x-ray diffraction methods. The types of fracture and the tensile fracture mechanisms of the LPBF Ti6Al4V ELI alloy were also studied. Detailed analysis of the microstructure and the corresponding mechanical properties were compared against standard specifications for conventional Ti6Al4V alloy for use in surgical implant applications. Conclusions regarding the mechanical properties and heat treatment of LPBF Ti6Al4V ELI for biomedical applications are made.

Similar content being viewed by others

References

A. du Plessis, S.G. le Roux, and A. Guelpa, Nucl. Instrum. Methods B 384, 42 (2016).

M. Simonelli, Microstructure Evolution and Mechanical Properties of Selective Laser Melted Ti-6Al-4V, PhD thesis (Loughborough University, UK, 2014)

P. Krakhmalev, G. Fredriksson, I. Yadroitsava, N. Kazantseva, A. du Plessis, and I. Yadroitsev, Phys. Procedia 83, 778 (2016).

F.X.G. Mur, D. Rodriguez, and J.A. Planell, J. Alloys Compd. 234, 287 (1996).

I. Yadroitsava, S. Grewar, D. Hattingh, and I. Yadroitsev, Mater. Sci. Forum 828–829, 305 (2015).

H.K. Rafi, N.V. Karthik, H. Gong, T.L. Starr, and B.E. Stucker, J. Mater. Eng. Perform. 22, 3873 (2015).

P. Edwards and M. Ramulu, Fatig. Fract. Eng. Mater. Struct. 38, 1228 (2015).

N.M. Dhansay, R. Tait, and T. Becker, Adv. Mater. Res. 1019, 248 (2014).

S. Wen, S. Li, Q. Wei, C. Yan, S. Zhang, and Y. Shi, J. Mater. Process. Technol. 214, 2660 (2014).

M.G. Moletsane, P. Krakhmalev, N. Kazantseva, A. du Plessis, I. Yadroitsava, I. Yadroitsev, S. Afr. J. Ind. Eng. 27, 110 (2016).

Acknowledgements

This work is based on research supported by the South African Research Chairs Initiative of the Department of Science and Technology and National Research Foundation of South Africa (Grant No. 97994) and the Collaborative Program in Additive Manufacturing (Contract No. CSIR-NLC-CPAM-15-MOA-CUT-01).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yadroitsev, I., Krakhmalev, P., Yadroitsava, I. et al. Qualification of Ti6Al4V ELI Alloy Produced by Laser Powder Bed Fusion for Biomedical Applications. JOM 70, 372–377 (2018). https://doi.org/10.1007/s11837-017-2655-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-017-2655-5