Abstract

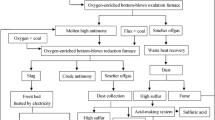

A pyrometallurgical process for the direct reduction of molten high-lead smelting slag obtained by the Shuikoushan (SKS) method was reported in this article using solid anthracite as the fuel and reductant. The chemical composition, the lead phase composition, and the physical properties of the molten high-lead slag were examined. The effects of the process parameters on the recovery rate of valued metals were investigated in the laboratory. According to the experimental results, a new efficient bottom blow reduction furnace was employed in the pilot-scale test for high-lead slag reduction. The results showed the average recovery rate of lead was more than 96.0% with lower Pb and high Zn content of the reducing slag under the condition of reduction temperature 1100–1200°C, coal ratio 5.5–7.5%, reduction time 90–150 min, CaO/SiO2 ratio 0.35–0.45, and FeO/SiO2 ratio 1.4–1.55. Moreover, nearly 250 kg of standard coal per ton of crude Pb output was reduced compared with the blast furnace reduction process.

Similar content being viewed by others

References

X.F. Zhu, L. Li, X.J. Sun, D.N. Yang, L.X. Gao, J.W. Liu, R. Vasant Kumar, and J.K. Yang, Hydrometallurgy 117, 24 (2012).

A.G. Matyas and P.J. Mackey, JOM 28, 10 (1976).

G.P. Ye, Nonferrous Metals (Extractive Metallurgy) 4, 20 (2000).

D.Y. Xu, Nonferrous Metals (Extractive Metallurgy) 6, 11 (2006).

P.E. Queneau, JOM 41, 30 (1989).

P.E. Queneau and A. Siegmund, JOM 48, 38 (1996).

L. Chen, T. Yang, S. Bin, W. Liu, D. Zhang, W. Bin, and L. Zhang, JOM 66, 1664 (2014).

K. Ramus and P. Hawkins, J. Power Sources 42, 299 (1993).

R.B.M. Brew, C.R. Fountain, and J. Pritchard, ISASMELT for Second Lead Smelting, Lead 90: 10th International Lead Conference (The Lead Development Association). 170 (1991).

L. Zhang, G.M. Lin, W.D. Bin, Y.X. Li, and X.B. Li, China Nonferrous Metall. 2, 12 (2012).

Acknowledgements

The authors would like to express sincere thanks to the National High Technology Research and Development Program of China in supporting this research project (2011AA061002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, W., Zhan, J., Fan, Y. et al. Research and Industrial Application of a Process for Direct Reduction of Molten High-Lead Smelting Slag. JOM 69, 784–789 (2017). https://doi.org/10.1007/s11837-016-2236-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-016-2236-z