Abstract

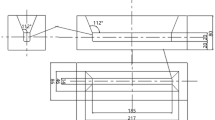

A combined multipass hot and cold drawing process was implemented to manufacture ultra-thin wires of the magnesium alloy MgCa0.8 with a final diameter of 0.05 mm. Numerical simulations were applied to design the drawing process of 40 passes regarding the microstructure evolution. To parametrize the model, in situ tensile tests were performed. Analysis of the MgCa0.8 wires featuring diameters below 0.1 mm revealed no intergranular crack initiation. The grain size of the ultra-thin wires is within the range of 30–500 nm with grains elongated in the drawing direction. The fine-grained microstructure provides high mechanical strength properties.

Similar content being viewed by others

References

J.M. Seitz, E. Wulf, P. Freytag, D. Bormann, and F.-W. Bach, Adv. Eng. Mater. 12, 1099 (2010).

F. Witte, J. Fischer, J. Nellesen, H.-A. Crostack, V. Kaese, A. Pisch, F. Beckmann, and H. Windhagen, Biomaterials 27, 1013 (2006).

J. Eickemeyer, A. Guth, M. Falter and R. Opitz, in Magnesium: Proceedings of the 6th International Conference on Magnesium alloys and their Applications, ed. K.U. Keiner. (Weinheim: WILEY-VCH Verlag GmbH & Co. KGaA, 2003) pp. 318–323.

K. Yoshida, Steel GRIPS 2, 199 (2004).

A. Milenin and P. Kustra, Arch. Metall. Mater. 58, 55 (2013).

A. Milenin and P. Kustra, Steel Research International Special edition the 14th International Conference on Metal Forming, ed. J. Kusiak, J. Majta and D. Szeliga, (Weinheim: Wiley-VCH Verlag GmbH & Co. KGaA 2012) pp. 839–842.

A. Milenin, P. Kustra, and D.J. Byrska-Wójcik, Arch. Metall. Mater. 57, 1117 (2012).

A. Milenin, P. Kustra, and D. Byrska-Wójcik, Adv. Eng. Mater. 16, 202 (2014).

A. Milenin, P. Kustra, and M. Pietrzyk, Key Eng. Mater. 622–623, 651 (2014).

A. Milenin, D.J. Byrska, and O. Grydin, Comput. Struct. 89, 1038 (2011).

A. Milenin, D.J. Byrska, O. Grydin, and M. Shaper, Comput. Methods Mater. Sci. 10, 61 (2010).

H.E. Friedrich and B.L. Mordike, Magnesium Technology, 1st ed. (Berlin: Springer, 2006).

A. Milenin, P. Kustra, and M. Paćko, Comput. Methods Mater. Sci. 10, 69 (2010).

C.M. Sellars, in Proceedings of International Conference on Hot Working and Forming Processes, (Metals Society 1979), pp. 3–15.

L.P. Karjalainen and J. Perttula, ISIJ Int. 36, 729 (1996).

A. Milenin, P. Kustra, D. Byrska-Wójcik, and M. Pietrzyk, Comput. Methods Mater. Sci. 15, 481 (2015).

A. Milenin and P. Kustra, Method and Apparatus for Performing of Wire Drawing Process of the Hardly Deformable Magnesium Alloys, Poland; Patent PL 221561 B1; publ. 2016-04-29.

Acknowledgements

The work was performed within the Project AGH No. 11.11.110.291 under the support of the Ministry of Science and High Education of Poland.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Milenin, A., Kustra, P., Byrska-Wójcik, D. et al. Analysis of Microstructure and Damage Evolution in Ultra-Thin Wires of the Magnesium Alloy MgCa0.8 at Multipass Drawing. JOM 68, 3063–3069 (2016). https://doi.org/10.1007/s11837-016-2127-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-016-2127-3