Abstract

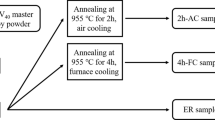

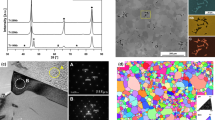

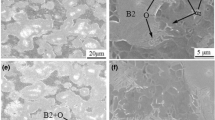

Ultra-high strength and ductile powder metallurgy (PM) binary Ti-20at.%Ta alloy has been fabricated via sintering from elemental Ti and Ta powders and subsequent hot swaging and annealing. The microstructural evolution and mechanical properties in each stage were evaluated. Results show that inhomogeneous microstructures with Ti-rich and Ta-rich areas formed in the as-sintered Ti-Ta alloys due to limited diffusion of Ta. In addition, Kirkendall porosity was observed as a result of the insufficient diffusion of Ta. Annealing at 1000°C for up to 24 h failed to eliminate the pores. Hot swaging eliminated the residual sintering porosity and created a lamellar microstructure, consisting of aligned Ta-enriched and Ti-enriched phases. The hot-swaged and annealed PM Ti-20Ta alloy achieved an ultimate tensile strength of 1600 MPa and tensile elongation of more than 25%, due to its unique lamellar microstructure including the high toughness of Ta-enriched phases, the formation of α phase in the β matrix and the refined lamellae.

Similar content being viewed by others

Change history

15 May 2018

The editors and authors have retracted the article, “Ultra-High Strength and Ductile Lamellar-Structured Powder Metallurgy Binary Ti-Ta Alloys” by Yong Liu, Shenghang Xu, Xin Wang, Kaiyang Li, Bin Liu, Hong Wu, and Huiping Tang (https://doi.org/10.1007/s11837-015-1801-1).

References

X. Xu and P. Nash, Mater. Sci. Eng. A 607, 409 (2014).

E. Delvat, D.M. Gordin, T. Gloriant, J.L. Duval, and M.D. Nagel, J. Mech. Behav. Biomed. Mater. 1, 345 (2008).

F. Xie, X. He, S. Cao, M. Mei, and X. Qu, Electrochim. Acta 105, 121 (2013).

V.A. Baheti, S. Roy, R. Ravi, and A. Paul, Intermetallics 33, 87 (2013).

O. Minho, G. Vakanas, N. Moelans, M. Kajihara, and W. Zhang, Microelectron. Eng. 120, 133 (2014).

S. Zhou, Y. Fan, Y. He, and N. Xu, J. Membr. Sci. 325, 546 (2008).

H. Gao, Y. He, P. Shen, J. Zou, N. Xu, Y. Jiang, B. Huang, and C.T. Liu, Intermetallics 17, 1041 (2009).

H.X. Dong, Y.H. He, Y. Jiang, L. Wu, J. Zou, N.P. Xu, B.Y. Huang, and C.T. Liu, Mater. Sci. Eng. A 528, 4849 (2011).

H.S. Park, K.L. Park, and S.K. Hwang, Mater. Sci. Eng. A 50, 329 (2002).

P.D. Edwards and M. Ramulu, J. Mater. Process. Technol. 218, 107 (2015).

W.F. Ho, C.P. Ju, and C. Lin, Biomaterials 20, 2115 (1999).

D.R. Correa, F.B. Vicente, T.A. Donato, V.E. Arana-Chavez, M.A. Buzalaf, and C.R. Grandini, Mater. Sci. Eng. C Mater. Biol. Appl. 34, 354 (2014).

H.Y. Kim, Y. Ikehara, J.I. Kim, H. Hosoda, and S. Miyazaki, Acta Mater. 54, 2419 (2006).

Y.L. Zhou, M. Niinomi, T. Akahori, H. Fukui, and H. Toda, Mater. Sci. Eng. A 398, 28 (2005).

Y.L. Zhou, M. Niinomi, and T. Akahori, Mater. Sci. Eng. A 384, 92 (2004).

Y.-L. Zhou and M. Niinomi, J. Alloys Compd. 466, 535 (2008).

R.J. Talling, R.J. Dashwood, M. Jackson, and D. Dye, Acta Mater. 57, 1188 (2009).

Y. Liu, K. Li, H. Wu, M. Song, W. Wang, N. Li, and H. Tang, J. Mech. Behav. Biomed. Mater. 51, 302 (2015).

W. Xu, M. Brandt, S. Sun, J. Elambasseril, Q. Liu, K. Latham, K. Xia, and M. Qian, Acta Mater. 85, 74 (2015).

B. Zhang, X. Li, and D. Li, Calphad 43, 7 (2013).

H. Wangyu, Q. Weihong, and Z. Bangwei, J. Hunan Univ. 26, 10 (1999).

M.-H. Cai, C.-Y. Lee, S. Kang, and Y.-K. Lee, Scr. Mater. 64, 1098 (2011).

Y.L. Zhou, M. Niinomi, and T. Akahori, Mater. Sci. Eng. A 371, 283 (2004).

W. Kochmann, M. Reibold, R. Goldberg, W. Hauffe, A.A. Levin, D.C. Meyer, T. Stephan, H. Müller, A. Belger, and P. Paufler, J. Alloys Compd. 372, L15 (2004).

Acknowledgements

The authors gratefully acknowledge the financial support from the National High Technology Research and Development Program of China (863 Program) (No. 2013AA031103), Shenzhen Municipal Science and Technology Plan (CXY201107010187A), and the Project of Innovation-driven Plan in Central South University (2015CX004).

Author information

Authors and Affiliations

Corresponding author

Additional information

The editors and authors have retracted this article. Following publication, the authors found that the data reported in Figure 11 is incorrect due to a hidden problem with their testing instrument. As a result of the error, a significant portion of the published article is incorrect. All authors agree to this retraction

About this article

Cite this article

Liu, Y., Xu, S., Wang, X. et al. RETRACTED ARTICLE: Ultra-High Strength and Ductile Lamellar-Structured Powder Metallurgy Binary Ti-Ta Alloys. JOM 68, 899–907 (2016). https://doi.org/10.1007/s11837-015-1801-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1801-1