Abstract

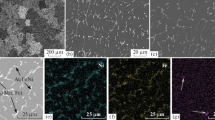

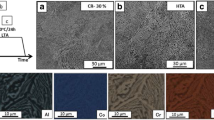

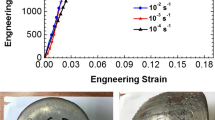

A cast AlCoCrCuFeNi high-entropy alloy was multiaxially forged at 950°C to produce a fine homogeneous mixture of grains/particles of four different phases with the average size of ~2.1 μm. The forged alloy exhibited unusual superplastic behavior accompanied by a pronounced softening stage, followed by a steady-state flow stage, during tensile deformation at temperatures of 800°C–1000°C and at strain rates of 10−4–10−1 s−1. Despite the softening stage, no noticeable strain localization was observed and a total elongation of up to 1240% was obtained. A detailed analysis of the phase composition and microstructure of the alloy before and after superplastic deformation was conducted, the strain rate and temperature dependences of the flow stress were determined at different stages of the superplastic deformation, and the relationships between the microstructure and properties were identified and discussed.

Similar content being viewed by others

References

J.-W. Yeh, S.-K. Chen, S.-J. Lin, J.-Y. Gan, T.-S. Chin, T.T. Chun, C.H. Tsau, and S.-Y. Chang, Adv. Eng. Mater. 6, 299 (2004).

J.-W. Yeh, Ann. Chim. Sci. Mater. 31, 633 (2006).

J.-W. Yeh, Y.-L. Chen, S.-J. Lin, and S.-K. Chen, Mater. Sci. Forum 560, 1 (2007).

Y.J. Zhou, Y. Zhang, Y.L. Wang, and G.L. Chen, Mater. Sci. Eng. A 454–455, 260 (2007).

Y.J. Zhou, Y. Zhang, Y.L. Wang, and G.L. Chen, Appl. Phys. Lett. 90, 180904 (2007).

Y.J. Zhou, Y. Zhang, F.J. Wang, Y.L. Wang, and G.I. Chen, J. Alloys Compd. 466, 201 (2008).

Y.P. Wang, B.S. Li, M.X. Ren, C. Yang, and H.Z. Fu, Mater. Sci. Eng. A 491, 154 (2008).

F.J. Wang and Y. Zhang, Mater. Sci. Eng. A 496, 214 (2008).

L.H. Wen, H.C. Kou, J.S. Li, H. Chang, X.Y. Xue, and L. Zhou, Intermetallics 17, 266 (2009).

C.W. Tsai, M.H. Tsai, J.W. Yeh, and C.C. Yang, J. Alloys Compd. 490, 160 (2010).

J.M. Zhu, H.M. Fu, H.F. Zhang, A.M. Wang, H. Li, and Z.H. Hu, Mater. Sci. Eng. A 527, 6975 (2010).

O.N. Senkov, G.B. Wilks, J.M. Scott, and D.B. Miracle, Intermetallics 19, 698 (2011).

O.N. Senkov, J.M. Scott, S.V. Senkova, D.B. Miracle, and C.F. Woodwart, J. Alloys Compd. 509, 6043 (2011).

S. Singh, N. Wanderka, B.S. Murty, U. Glatzel, and J. Banhart, Acta Mater. 50, 182 (2011).

T.T. Shun, C.-H. Hung, and C.-F. Lee, J. Alloys Compd. 493, 105 (2010).

Y.P. Wang, B.S. Li, and H.Z. Fu, Adv. Eng. Mater. 11, 641 (2009).

C.-W. Tsai, Y.-L. Chen, M.-H. Tsai, J.-W. Yeh, T.-T. Shun, and S.K. Chen, J. Alloys Compd. 486, 427 (2009).

O.N. Senkov, G.B. Wilks, D.B. Miracle, C.P. Chuang, and P.K. Liaw, Intermetallics 18, 1758 (2010).

A.V. Kuznetsov, D.G. Shaysultanov, N.D. Stepanov, G.A. Salishchev, and O.N. Senkov, Mater. Sci. Eng. A 533, 107 (2012).

A.V. Kuznetsov, D.G. Shaysultanov, N.D. Stepanov, G.A. Salishchev, and O.N. Senkov, Mater. Sci. Forum 735, 146 (2013).

A.M. Soifer, A. Verdyan, M. Kazakevich, and E. Rabkin, Scr. Mater. 47, 799 (2004).

T. Ohmura, K. Tsuzaki, K. Sawada, and K. Kimura, J. Mater. Res. 21, 1229 (2003).

G.E. Dieter, Mechanical Metallurgy, 3rd ed. (New York, NY: McGraw-Hill, Inc., 1986).

H.J. McQueen and J.J. Jonas, Treatise on Materials Science and Technology, vol. 6, ed. R.J. Arsenault (New York, NY: Academic Press, 1975), pp. 393–493.

J.J. Jonas, C.M. Sellars, and W.J.Mc.G. Tegart, Met Rev. 14, 1 (1969).

G. Effenberg, Landolt–Bornstein. Numerical Data and Functional Relationships in Science and Technology. New Series IV/11A2 (Stuttgart: MSIT Material Science International Team, 2005), pp. 104–126.

T.G. Nieh, J. Wadsworth, and O.D. Sherby, Superplasticity in Metals and Ceramics Cambridge Solid State Science Series (Cambridge, MA: Cambridge University Press, 1997).

C.M. Lin and H.L. Tsai, Mater. Chem. Phys. 128, 50 (2011).

Ch.-Ch. Hsieh and W. Wu, ISRN Metallurgy Article ID 732491 (2012).

Z. Liu, S. Guo, X. Liu, J. Ye, Y. Yang, X.-L. Wang, L. Yang, K. An, and C.T. Liu, Scr. Mater. 64, 868 (2011).

G. Effenberg, Landolt–Bornstein. Numerical Data and Functional Relationships in Science and Technology. New Series IV/11D2 (Stuttgart: MSIT Material Science International Team, 2005), pp. 1–36.

The Stainless Steel information Center, High Temperature Properties, http://www.ssina.com/composition/temperature.html. Accessed 17 Aug 2013.

R. Darolia, JOM 43, 44 (1991).

O.A. Kaibyshev, Superplasticity of Alloys, Intermetallides and Ceramics (Berlin: Springer, 1992).

R.M. Imayev, O.A. Kaibyshev, and G.A. Salishchev, Acta Metall. 40, 581 (1992).

K.Y. Tsai, M.H. Tsai, and J.W. Yeh, Acta Mater. 61, 4887 (2013).

C. Ng, S. Guo, J. Luan, S. Shi, and C.T. Liu, Intermetallics 31, 165 (2012).

C. Zhang, F. Zhang, S. Chen, and W. Cao, JOM 64, 839 (2012).

D.B. Butrymowicz, J.R. Manning, and M.E. Read, J. Phys. Chem. Ref. Data 2, 643 (1973).

M. Sakamoto, J. Phys. Soc. Jpn. 13, 845 (1958).

A.A. Vasilyev, S.F. Sokolov, N.G. Kolbasnikov, and D.F. Sokolov, Phys. Solid State 53, 2194 (2011).

H.J. Frost and M.F. Ashby, Fundamental Aspects of Structural Alloy Design (New York, NY: Plenum Press, 1977).

S. Meagher, R.S. Borch, J. Groza, A.K. Mukherjee, and H.W. Green II, Acta Metall. Mater. 40, 159 (1992).

A. Chaudhuri, Met. Sci. 3, 159 (1969).

J.L. Campbell and C.W. Schulte, J. Appl. Phys. 19, 149 (1979).

W. Ren, J. Guo, G. Li, and J. Wu, Mater. Trans. 42, 1731 (2004).

M.E. Kassner and M.T. Pérez-Prado, Fundamentals of Creep in Metals and Alloys (Amsterdam: Elsevier, 2004).

Acknowledgement

The financial support from the Ministry of Science and Education of Russian Federation through the Grant No. 02.11.740.5184 is kindly appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shaysultanov, D.G., Stepanov, N.D., Kuznetsov, A.V. et al. Phase Composition and Superplastic Behavior of a Wrought AlCoCrCuFeNi High-Entropy Alloy. JOM 65, 1815–1828 (2013). https://doi.org/10.1007/s11837-013-0754-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-013-0754-5