Abstract

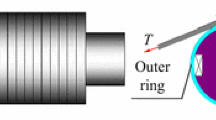

A high-precision shape detecting system of cold rolling strip is developed to meet industrial application, which mainly consists of the shape detecting roller, the collecting ring, the digital signal processing (DSP) shape signal processing board and the shape control model. Based on the shape detecting principle, the shape detecting roller is designed with a new integral structure for improving the precision of shape detecting and avoiding scratching strip surface. Based on the DSP technology, the DSP shape signal processing circuit board is designed and embedded in the shape detecting system for the reliability and stability of shape signal processing. The shape detecting system was successfully used in Angang 1 250 mm HC 6-high reversible cold rolling mill. The precision of shape detecting is 0.2 I and the shape deviation is controlled within 6 I after the close loop shape control is input.

Similar content being viewed by others

References

XU Le-jiang. Shape control and mill type selection of cold mill strip [M]. Beijing: Metallurgical Industry Press, 2007: 100–124.

WANG Guo-dong. Shape control and shape theory [M]. Beijing: Metallurgical Industry Press, 1986: 41–97.

LIAN Jia-chuang, LIU Hong-min. Control of strip thickness and shape [M]. Beijing: Enginery Industry Publishing Company, 1996: 10–49.

WANG Jun-sheng, BAI Jin-lan, LIU Xiang-hua. Theory and process control of cold strip rolling [M]. Beijing: Science Press, 2009: 1–25.

YANG Li-hong, YAN Fei, MA Zhao-hui. Research and development of pre-coated steel for automotive industry [J]. Iron and Steel, 2009, 44(12): 1–7.

ZHAI Bo, SUN Rong-sheng, SUN Jian-lin. Application of sheet shape control technology on continuous rolling mills in Angang [J]. Aisc Techniques, 2009, 355(1): 49–52.

HU Guo-dong, WANG Qi, ZOU Ben-you. Differential output shape meter of mageto-elastic transformer for cold rolling strip [J]. Iron and Steel, 1994, 29(4): 56–59.

XU Shi-min, YU Bing-qiang, HU Guo-dong. Shape meter of pressing magnetic type for cold rolling strip to applicating 4-roller reversible rolling mill [J]. Metallurgical Equipment, 2004, 147(5): 39–40.

ZHAO Qi-lin, WANG Jun-sheng, WANG Guo-dong. Development and application of a measured flatness value processing method [J]. Journal of Materials and Metallurgy, 2009, 8(4): 294–296.

WANG Jun-sheng, JIANG Zheng-yi. A flying gauge change model in tandem cold strip mill [J]. Journal of Materials Processing Technology, 2008, 201(1/2/3): 152–161.

LIU Jian, WANG Yi-qun, HU Xiao-jun. Dynamic calibration of pneumatic strip shape measuring rolls and phase correction compensation method of system circumferential error [J]. Steel Rolling, 2009, 26(1): 26–29.

SUN Xu-guang, WANG Yi-qun, YIN Guo-fang. Main technical performance of pneumatic strip shape measuring roll [J]. Journal of Iron and Steel Research, 2006, 18(12): 47–49.

LIU Hong-min, DING Kai-rong, LI Xing-dong. Theoretical computational method of shape standard curve [J]. Chinese Journal of Mechanical Engineering, 2008, 44(8): 137–142.

LIU Hong-min, HE Hai-tao, SHAN Xiu-ying. Flatness control based on dynamic effective matrix for cold strip mills [J]. Chinese Journal of Mechanical Engineering, 2009, 22(2): 287–296.

SUN Ya-bo, LIU Hong-min, PENG Yan. Influence of variation of the on_line shape of cold rolled strip on shape measuring and controlling system and its compensating measures [C]// Proceedings of Second International Conference on Modeling and Simulation. Liverpool, UK, 2009: 212–219.

YU Bing-qiang, LIU Hong-min, YANG Li-po. A new type of contact shape meter and its industry application [C]// International Conference on Measuring Technology and Mechatronics Automation (ICMTMA2009). Zhangjiajie, China, 2009: 1058–1061.

LI Zhi-ming, PENG Yan, YU Bing-qiang. A shape measurement system for cold-rolled steel strip based on DSP [C]// 2009 WASE International Conference on Information Engineering. Dalian, China, 2009: 257–260.

LIU Hong-min, YANG Li-po, YU Bing-qiang. Entire-inlayed-block-intelligence-type shape meter [P]. Chinese Patent: CN101694368A, 2010-04-07. (in Chinese)

YU Bing-qiang, YANG Li-po, LIU Hong-min. Development and industry application of contact shape meter with new structure [J]. Chinese Journal of Scientific Instrument, 2010, 31(4): 904–911.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(2009AA04Z143) supported by the National High Technology Research and Development Program of China; Project (E2011203004) supported by Natural Science Foundation of Hebei Province, China; Projects(2011BAF15B03, 2011BAF15B02) supported by the National Science Plan of China

Rights and permissions

About this article

Cite this article

Yang, Lp., Yu, Bq., Ding, D. et al. Industrial shape detecting system of cold rolling strip. J. Cent. South Univ. Technol. 19, 994–1001 (2012). https://doi.org/10.1007/s11771-012-1102-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-012-1102-6