Abstract

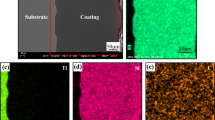

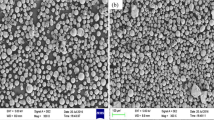

The effect of surface finish and annealing treatment on the oxidation behavior of Ti-48Al-8Cr-2Ag (molar fraction, %) alloy was investigated at 900 and 1 000 °C, respectively in air. Thermal gravimetric analysis (TGA) was conducted for the characterization of oxidation kinetics. The microstructures of oxide scales were studied by scanning electron microscopy (SEM) and transmission election microscopy (TEM) techniques. Unfavorable effect of the annealing treatment on the oxidation behavior of the coating was also investigated. The results indicate that the oxidation behavior of the alloy is influenced by surface finish and annealing treatment. The oxidation rate of ground sample is lower than that of the polished alloy at 1 000 °C in air. The former forms a scale of merely Al2O3, and the latter forms a scale of the mixture of Al2O3 and TiO2. Annealing can improve the formation of TiO2.

Similar content being viewed by others

References

ZHU Ming, LI Mei-shuan, DUO Shu-wang, ZHOU Yan-chun. Improvement on the oxidation resistance of a Ti3Al based alloy by Cr1−xAlxN (0≤x≤0.47) coating [J]. J Mater Sci Technol A, 2007, A23(3): 373–379.

FUKUMOTO M, HARA M, NAGATAKI T. Effect of Al electrodeposition treatment using molten salt on the high-temperature oxidation of TiAl [J]. Oxidation of Metals, 2004, 61(1/2): 1–6.

XIONG Yu-ming, ZHU Sheng-long, WANG Fu-hui, LEE Chang-hee. Effect of vitreous enamel coating on the oxidation behavior of Ti6Al4V and TiAl alloys at high temperatures [J]. J Coat Technol Res, 2008, 5(1): 93–98.

BECKER S, RAHMEL A, SCHORR M, SCHUTZE M. Mechanism of isothermal oxidation of the intermetallic TiAl and of TiAl alloys [J]. Oxid Met, 1992, 38: 425–429.

DETTENWANGER F, SCHUMANN E, RUHLE M, RAKOWSKI J J, MERIER G H. Microstructure study of oxidized γ-TiAl [J]. Oxid Met, 1998, 50: 269–275.

XIANG Z D, ROSE S R, DATTA P K. Codeposition of Al and Si to form oxidation-resistant coatings on TiAl by the pack cementation process [J]. Mater Chem Phi, 2003, 80: 482–489.

NISHIMOTO T, IZUMI T, SHIGENARI, SHIGENARI, NATITA T. Two-step Cr and Al diffusion coating on TiAl at high temperatures [J]. Intermetallics, 2003, 11: 225–235.

NISHIMOTO T, IZUMI T, SHIGENARI, SHIGENARI, NATITA T. Effect of coating layer structures and surface treatments on the oxidation behavior of a Ti-50 at.%Al alloy [J]. Intermetallics, 2003, 11: 459–466.

MARIE-PIERRE B, BENOIT G, PIEERE J, CATHERINE R. MCrAlY coating developed via a new electroless-like route: Influence of deposition parameters [J]. Surf Coat Technol, 2003, 162:248–260.

WANG F, LOU H, WU W. The oxidation resistance of a sputtered microcrystalline TiAl intermetallic-compound film [J]. Oxid Met 1995, 43: 395–409.

TANG Z, WANG F, WU W. Effect of a sputtered TiAlCr coating on the oxidation resistance of TiAl intermetallic compound [J]. Oxid Met, 1997, 48: 511–525.

XI Yan-jun, WANG Fu-hui, HE Lian-long. Oxidation and hot-corrosion behavior of sputtered Ti-48Al-8Cr-2Ag nanocrystalline coating [J]. Mater Sci Forum, 2004, 461: 1181–1187.

BRADY M P, SMIALEK J L, SMITH J. The role of Cr promoting protective aluminia scale formation by γ-based Ti-Al-Cr alloys: Compatibility with alumina and oxidation behavior in oxygen [J]. Acta Metall Meter, 1997, 45: 2357–2369.

BRADY M P, SMIALEK J L, HUMPHRAY D L. The role of Cr in promotion protective alumina scale formation by γ-based Ti-Al-Cr alloys—Oxidation behavior in air [J]. Acta Metall Meter, 1997, 45:2371–2382.

TANG Z, SHEMET V, NIEWOLAK L, QUADAKKERS W J. Intermetallics: Effect of Cr addition on oxidation behavior of Ti-48Al-2Ag alloys [J]. Intermetallics, 2003, 11: 1–8.

MURRIS I, JACOB Y P, HAANAPPEL V A C, STROOSNIJDER M F. High-temperature oxidation behavior of chromium: Effect of different batches [J]. Oxid Met, 2001, 55: 307–331.

LEYENS C, SCHMIDT M, PETERS M, KAYSSER W A. Sputtered intermetallic Ti-Al-X coatings: Phase formation and oxidation behavior [J]. Meter Sci Eng A, 1997, 239/240: 680–687.

XI Yan-jun, LU Wei, GUO Chang-you, HE Lian-long, WANG Fu-hui. Microstructure of oxide scale formed on Ti-48Al-8Cr-2Ag alloy in air at 900–1 000 °C [J]. Oxid Met, 2005, 63(3): 229–239.

PERKINS R A, CHIANG KT, MEIER G H. Formation of alumina on Ti-Al alloys [J]. Scripta Metallurgica, 1987, 21(11): 1505–1510.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(2007430028) supported by the Science and Technique Foundation of Henan Educational Committee, China

Rights and permissions

About this article

Cite this article

Xi, Yj., Liu, Yj. Influence of surface finish and annealing treatment on oxidation behavior of Ti-48Al-8Cr-2Ag alloy. J. Cent. South Univ. Technol. 16, 541–545 (2009). https://doi.org/10.1007/s11771-009-0090-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-009-0090-7