Abstract

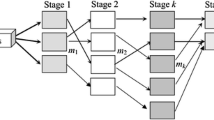

In the flow shop rescheduling literature, many papers consider unlimited buffer capacities between successive machines. In real fact, these capacities may be limited, or no store may exist. Thus, a blocking situation is inducted. Diverse types of blocking constraints are studied in the flow shop scheduling problems. However, in dynamic environments, only few papers deal with these kinds of constraints. The aim of this paper is to investigate a problem of rescheduling the jobs in a flowshop environment and mixed blocking as a constraint, considering simultaneously schedule efficiency and stability as a performance measure, and job arrival as a disruption. An iterative methodology based on the predictive–reactive strategy is implemented for dealing with this rescheduling problem. The problem has first been modeled as a Mixed Integer Linear Programing (MILP) model. Experimental results show that the MILP resolution is only possible for small-sized instances. Hence, inspired by NEH algorithm, we proposed four heuristics for solving large-sized instances of this problem. Eventually, we discussed the performance of the proposed heuristics for different blocking situations, both in terms of solution efficiency and resolution time.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author, AT, upon reasonable request.

References

Akkan C (2015) Improving schedule stability in single-machine rescheduling for new operation insertion. Comput Oper Res 64:198–209

Akyol Ozer E, Sarac T (2019) MIP models and a matheuristic algorithm for an identical parallel machine scheduling problem under multiple copies of shared resources constraints. TOP 27(1):94–124

Auer P, Dósa G, Dulai T, Fügenschuh A, Näser P, Ortner R, Werner-Stark Á (2021) A new heuristic and an exact approach for a production planning problem. CEJOR 29(3):1079–1113

Bautista-Valhondo J, Alfaro-Pozo R (2020) Mixed integer linear programming models for Flow Shop Scheduling with a demand plan of job types. CEJOR 28(1):5–23

Braune R, Gutjahr WJ, Vogl P (2022) Stochastic radiotherapy appointment scheduling. CEJOR 30(4):1239–1277

De La Vega J, Moreno A, Morabito R, Munari P (2023) A robust optimization approach for the unrelated parallel machine scheduling problem. TOP 31(1):31–66

Druetto A, Pastore E, Rener E (2022) Parallel batching with multi-size jobs and incompatible job families. Top 31(2):440–458

Guo Y, Xie X (2017) Two mixed integer programming formulations on single machine to reschedule repaired jobs for minimizing the total waiting-time. Chinese Automation Congress (CAC), IEEE, pp 2129–2133

Gürel S, Körpeoğlu E, Aktürk MS (2010) An anticipative scheduling approach with controllable processing times. Comput Oper Res 37(6):1002–1013

Hall NG, Potts CN (2004) Rescheduling for new orders. Oper Res 52(3):440–453

Haroune M, Dhib C, Neron E, Soukhal A, Mohamed Babou H, Nanne MF (2022) Multi-project scheduling problem under shared multi-skill resource constraints. Top 31(1):194–235

He X, Dong S, Zhao N (2020) Research on rush order insertion rescheduling problem under hybrid flow shop based on NSGA-III. International journal of production research 58(4):1161–1177

Herrmann JW (2006) Rescheduling strategies, policies, and methods. Handbook of production scheduling. Springer, Boston, pp 135–148

Kacem A, Dammak A (2021) Multi-objective scheduling on two dedicated processors. TOP 29(3):694–721

Kan AR (1976) Problem formulation. Machine scheduling problems. Springer, Boston, pp 5–29

Katragjini K, Vallada E, Ruiz R (2013) Flow shop rescheduling under different types of disruption. Int J Prod Res 51(3):780–797

Kecman P, Corman F, D’Ariano A, Goverde RM (2013) Rescheduling models for railway traffic management in large-scale networks. Public Transp 5(1–2):95–123

Kovalyov MY, Kress D, Meiswinkel S, Pesch E (2019) A parallel machine schedule updating game with compensations and clients averse to uncertain loss. Comput Oper Res 103:148–157

Li Y, Carabelli S, Fadda E, Manerba D, Tadei R, Terzo O (2020) Machine learning and optimization for production rescheduling in Industry 4.0. Int J Adv Manuf Technol 110(9):2445–2463

Liu Z, Ro YK (2014) Rescheduling for machine disruption to minimize makespan and maximum lateness. J Sched 17(4):339–352

Liu L, Zhou H (2013) Open shop rescheduling under singular machine disruption. Comput Integr Manuf Syst 10:12

Lodree E Jr, Jang W, Klein CM (2004) A new rule for minimizing the number of tardy jobs in dynamic flow shops. Eur J Oper Res 159(1):258–263

Machado-Dominguez LF, Paternina-Arboleda CD, Vélez JI, Barrios-Sarmiento A (2022) An adaptative bacterial foraging optimization algorithm for solving the MRCPSP with discounted cash flows. TOP 30(2):221–248

Manzini M, Demeulemeester E, Urgo M (2022) A predictive–reactive approach for the sequencing of assembly operations in an automated assembly line. Robot Comput-Integr Manuf 73:102201

Martinez S, Dauzère-Pérès S, Gueret C, Mati Y, Sauer N (2006) Complexity of flowshop scheduling problems with a new blocking constraint. Eur J Oper Res 169(3):855–864

Mohan J, Lanka K, Rao NA, Manupati VK (2022) Sustainable flexible job shop scheduling: a systematic literature review. In: Global congress on manufacturing and management. Springer, Cham, pp 227–246

Mula J, Bogataj M (2021) OR in the industrial engineering of Industry 4.0: experiences from the Iberian Peninsula mirrored in CJOR. Central Eur J Oper Res 29(4):1163–1184

Nawaz M, Enscore EE Jr, Ham I (1983) A heuristic algorithm for the m-machine, n-job flow-shop sequencing problem. Omega 11(1):91–95

Ozolins A (2021) Dynamic programming approach for solving the open shop problem. CEJOR 29(1):291–306

Pitombeira-Neto AR, Prata BDA (2020) A matheuristic algorithm for the one-dimensional cutting stock and scheduling problem with heterogeneous orders. TOP 28(1):178–192

Prata BDA, de Abreu LR, Lima JYF (2021) Heuristic methods for the single-machine scheduling problem with periodical resource constraints. TOP 29(2):524–546

Rahmani D, Ramezanian R (2016) A stable reactive approach in dynamic flexible flow shop scheduling with unexpected disruptions: a case study. Comput Ind Eng 98:360–372

Sauvey C, Sauer N (2020) Two NEH heuristic improvements for flowshop scheduling problem with makespan criterion. Algorithms 13(5):112

Sauvey C, Trabelsi W, Sauer N (2020) Mathematical model and evaluation function for conflict-free warranted makespan minimization of mixed blocking constraint job-shop problems. Mathematics 8(1):121

Sayed SI, Contreras I, Diaz JA, Luna DE (2020) Integrated cross-dock door assignment and truck scheduling with handling times. TOP 28(3):705–727

Şenyiğit E, Atici U, Şenol MB (2022) Effects of OCRA parameters and learning rate on machine scheduling. Central Eur J Oper Res 30:941–959

Serrano-Ruiz JC, Mula J, Poler R (2021) Smart manufacturing scheduling: a literature review. J Manuf Syst 61:265–287

Serrano-Ruiz JC, Mula J, Poler R (2022) Development of a multidimensional conceptual model for job shop smart manufacturing scheduling from the Industry 4.0 perspective. J Manuf Syst 63:185–202

Tao Z, Liu X (2019) Dynamic scheduling of dual-resource constrained blocking job shop. In: International conference on intelligent robotics and applications. Springer, Cham, pp 447–456

Tighazoui A, Sauvey C, Sauer N (2020) New efficiency-stability criterion in a rescheduling problem with dynamic jobs weights. In: 2020 7th International Conference on Control, Decision and Information Technologies (CoDIT), vol 1, IEEE, pp 475–480

Tighazoui A, Sauvey C, Sauer N (2021a) Predictive-reactive strategy for flowshop rescheduling problem: minimizing the total weighted waiting times and instability. J Syst Sci Syst Eng 30:253–275

Tighazoui A, Sauvey C, Sauer N (2021b) Predictive-reactive strategy for identical parallel machine rescheduling. Comput Oper Res 134:105372

Trabelsi W, Sauvey C, Sauer N (2011) Complexity and mathematical model for flowshop problem subject to different types of blocking constraint. IFAC Proc Vol 44(1):8183–8188

Trabelsi W, Sauvey C, Sauer N (2012) Heuristics and metaheuristics for mixed blocking constraints flowshop scheduling problems. Comput Oper Res 39(11):2520–2527

Uhlmann IR, Zanella RM, Frazzon EM (2022) Hybrid flow shop rescheduling for contract manufacturing services. Int J Prod Res 60(3):1069–1085

Valledor P, Gomez A, Puente J, Fernandez I (2022) Solving rescheduling problems in dynamic permutation flow shop environments with multiple objectives using the hybrid dynamic non-dominated sorting genetic II algorithm. Mathematics 10(14):2395

Vieira GE, Herrmann JW, Lin E (2003) Rescheduling manufacturing systems: a framework of strategies, policies, and methods. J Sched 6(1):39–62

Wang L, Zhang L, Zheng DZ (2006) An effective hybrid genetic algorithm for flow shop scheduling with limited buffers. Comput Oper Res 33(10):2960–2971

Wu Q, Xie N, Zheng S, Bernard A (2022) Online order scheduling of multi 3D printing tasks based on the additive manufacturing cloud platform. J Manuf Syst 63:23–34

Xiao J, Osterweil LJ, Wang Q, Li M (2010) Dynamic resource scheduling in disruption-prone software development environments. International conference on fundamental approaches to software engineering. Springer, Berlin, pp 107–122

Yan P, Liu SQ, Sun T, Ma K (2018) A dynamic scheduling approach for optimizing the material handling operations in a robotic cell. Comput Oper Res 99:166–177

Yuan K, Sauer N, Sauvey C (2009) Application of EM algorithm to hybrid flow shop scheduling problems with a special blocking. In: 2009 IEEE conference on emerging technologies & factory automation, IEEE, pp 1–7. https://doi.org/10.1109/ETFA.2009.5347066

Zhang L, Gao L, Li X (2013) A hybrid intelligent algorithm and rescheduling technique for job shop scheduling problems with disruptions. Int J Adv Manuf Technol 65(5):1141–1156

Zhang L, Hu Y, Wang C, Tang Q, Li X (2022a) Effective dispatching rules mining based on near-optimal schedules in intelligent job shop environment. J Manuf Syst 63:424–438

Zhang X, Lin WC, Wu CC (2022b) Rescheduling problems with allowing for the unexpected new jobs arrival. J Comb Optim 43(3):630–645

Acknowledgements

This work is supported by the Urban Community of Sarreguemines-France and the Grand Est Region-France.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tighazoui, A., Sauvey, C. & Sauer, N. Heuristics for flow shop rescheduling with mixed blocking constraints. TOP (2023). https://doi.org/10.1007/s11750-023-00662-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11750-023-00662-8