Abstract

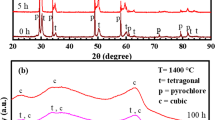

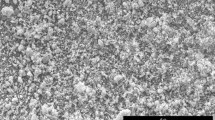

7-8 wt.% Yttria-stabilized zirconia (YSZ) is the standard thermal barrier coating (TBC) material used by the gas turbines industry due to its excellent thermal and thermo-mechanical properties up to 1200 °C. The need for improvement in gas turbine efficiency has led to an increase in the turbine inlet gas temperature. However, above 1200 °C, YSZ has issues such as poor sintering resistance, poor phase stability and susceptibility to calcium magnesium alumino silicates (CMAS) degradation. Gadolinium zirconate (GZ) is considered as one of the promising top coat candidates for TBC applications at high temperatures (>1200 °C) due to its low thermal conductivity, good sintering resistance and CMAS attack resistance. Single-layer 8YSZ, double-layer GZ/YSZ and triple-layer GZdense/GZ/YSZ TBCs were deposited by suspension plasma spray (SPS) process. Microstructural analysis was carried out by scanning electron microscopy (SEM). A columnar microstructure was observed in the single-, double- and triple-layer TBCs. Phase analysis of the as-sprayed TBCs was carried out using XRD (x-ray diffraction) where a tetragonal prime phase of zirconia in the single-layer YSZ TBC and a cubic defect fluorite phase of GZ in the double and triple-layer TBCs was observed. Porosity measurements of the as-sprayed TBCs were made by water intrusion method and image analysis method. The as-sprayed GZ-based multi-layered TBCs were subjected to erosion test at room temperature, and their erosion resistance was compared with single-layer 8YSZ. It was shown that the erosion resistance of 8YSZ single-layer TBC was higher than GZ-based multi-layered TBCs. Among the multi-layered TBCs, triple-layer TBC was slightly better than double layer in terms of erosion resistance. The eroded TBCs were cold-mounted and analyzed by SEM.

Similar content being viewed by others

References

R.A. Miller, Thermal Barrier Coatings for Aircraft Engines: History and Directions, J. Therm. Spray Technol., 1997, 6(1), p 35-42

D. Stöver and C. Funke, Directions of the Development of Thermal Barrier Coatings in Energy Applications, J. Mater. Process. Technol., 1999, 92–93, p 195-202

J.M. Drexler, C.-H. Chen, A.D. Gledhill, K. Shinoda, S. Sampath, and N.P. Padture, Plasma Sprayed Gadolinium Zirconate Thermal Barrier Coatings That are Resistant to Damage by Molten Ca–Mg–Al–Silicate Glass, Surf. Coat. Technol., 2012, 206(19–20), p 3911-3916

A.D. Gledhill, K.M. Reddy, J.M. Drexler, K. Shinoda, S. Sampath, and N.P. Padture, Mitigation of Damage from Molten Fly Ash to Air-Plasma-Sprayed Thermal Barrier Coatings, Mater. Sci. Eng. A, 2011, 528(24), p 7214-7221

L. Li, N. Hitchman, and J. Knapp, Failure of Thermal Barrier Coatings Subjected to CMAS Attack, J. Therm. Spray Technol., 2009, 19(1–2), p 148-155

A. Aygun, A.L. Vasiliev, N.P. Padture, and X. Ma, Novel Thermal Barrier Coatings that are Resistant to High-Temperature Attack by Glassy Deposits, Acta Mater., 2007, 55(20), p 6734-6745

A. Cipitria, I.O. Golosnoy, and T.W. Clyne, A Sintering Model for Plasma-Sprayed Zirconia TBCs. Part I: Free-Standing Coatings, Acta Mater., 2009, 57(4), p 980-992

S. Krämer, J. Yang, and C.G. Levi, Infiltration-Inhibiting Reaction of Gadolinium Zirconate Thermal Barrier Coatings with CMAS Melts, J. Am. Ceram. Soc., 2008, 91(2), p 576-583

S. Krämer, J. Yang, C.G. Levi, and C.A. Johnson, Thermochemical Interaction of Thermal Barrier Coatings with Molten CaO–MgO–Al2O3–SiO2 (CMAS) Deposits, J. Am. Ceram. Soc., 2006, 89(10), p 3167-3175

R. Vaßen, M.O. Jarligo, T. Steinke, D.E. Mack, and D. Stöver, Overview on Advanced Thermal Barrier Coatings, Surf. Coat. Technol., 2010, 205(4), p 938-942

N.P. Padture, M. Gell, and E.H. Jordan, Thermal Barrier Coatings for Gas-Turbine Engine Applications, Science, 2002, 296(5566), p 280-284

S. Mahade, N. Curry, S. Björklund, N. Markocsan, and P. Nylén, Thermal Conductivity and Thermal Cyclic Fatigue of Multilayered Gd2Zr2O7/YSZ Thermal Barrier Coatings Processed by Suspension Plasma Spray, Surf. Coat. Technol., 2015, 283, p 329-336

G. Moskal, L. Swadźba, M. Hetmańczyk, B. Witala, B. Mendala, J. Mendala, and P. Sosnowy, Characterization of Microstructure and Thermal Properties of Gd2Zr2O7-Type Thermal Barrier Coating, J. Eur. Ceram. Soc., 2012, 32(9), p 2025-2034

G. Mauer, M.O. Jarligo, D.E. Mack, and R. Vaßen, Plasma-Sprayed Thermal Barrier Coatings: New Materials, Processing Issues, and Solutions, J. Therm. Spray Technol., 2013, 22, p 646-658

R.M. Leckie, S. Krämer, M. Rühle, and C.G. Levi, Thermochemical Compatibility Between Alumina and ZrO2–GdO3/2 Thermal Barrier Coatings, Acta Mater., 2005, 53(11), p 3281-3292

E. Bakan, D.E. Mack, G. Mauer, and R. Vaßen, Gadolinium Zirconate/YSZ Thermal Barrier Coatings: Plasma Spraying, Microstructure, and Thermal Cycling Behavior, J. Am. Ceram. Soc., 2014, 97(12), p 4045-4051

X. Zhong, H. Zhao, C. Liu, L. Wang, F. Shao, X. Zhou, S. Tao, and C. Ding, Improvement in Thermal Shock Resistance of Gadolinium Zirconate Coating by Addition of Nanostructured Yttria Partially-Stabilized Zirconia, Ceram. Int., 2015, 41(6), p 7318-7324

K.S. Lee, D.H. Lee, and T.W. Kim, Microstructure Controls in Gadolinium Zirconate/YSZ Double Layers and Their Properties, J. Ceram. Soc. Jpn., 2014, 122(1428), p 668-673

J.R. Nicholls, M.J. Deakin, and D.S. Rickerby, A Comparison Between the Erosion Behaviour of Thermal Spray and Electron Beam Physical Vapour Deposition Thermal Barrier Coatings, Wear, 1999, 233–235, p 352-361

R.G. Wellman and J.R. Nicholls, A Review of the Erosion of Thermal Barrier Coatings, J. Phys. Appl. Phys., 2007, 40(16), p R293

P. Sokołowski, S. Kozerski, L. Pawłowski, and A. Ambroziak, The key Process Parameters Influencing Formation of Columnar Microstructure in Suspension Plasma Sprayed Zirconia Coatings, Surf. Coat. Technol., 2014, 260, p 97-106

N. Curry, Z. Tang, N. Markocsan, and P. Nylén, Influence of Bond Coat Surface Roughness on the Structure of Axial Suspension Plasma Spray Thermal Barrier Coatings—Thermal and Lifetime Performance, Surf. Coat. Technol., 2015, 268, p 15-23

N. Curry, K. VanEvery, T. Snyder, and N. Markocsan, Thermal Conductivity Analysis and Lifetime Testing of Suspension Plasma-Sprayed Thermal Barrier, Coatings, 2014, 4(3), p 630-650

S. Mahade, R. Li, N. Curry, S. Björklund, N. Markocsan, and P. Nylén, Isothermal Oxidation Behavior of Gd2Zr2O7/YSZ Multilayered Thermal Barrier Coatings, Int. J. Appl. Ceram. Technol., 2016, 13(3), p 443-450

C.S. Ramachandran, V. Balasubramanian, and P.V. Ananthapadmanabhan, Erosion of Atmospheric Plasma Sprayed Rare Earth Oxide Coatings Under Air Suspended Corundum Particles, Ceram. Int., 2013, 39(1), p 649-672

V. Viswanathan, G. Dwivedi, and S. Sampath, Multilayer, Multimaterial Thermal Barrier Coating Systems: Design, Synthesis, and Performance Assessment, J. Am. Ceram. Soc., 2015, 98(6), p 1769-1777

“ISO 18754:2013—Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)—Determination of Density and Apparent Porosity,” ISO. [Online]. http://www.iso.org/iso/iso_catalogue/catalogue_tc/catalogue_detail.htm?csnumber=55448

“ImageJ,” Softonic. [Online]. http://imagej.en.softonic.com/

N.A. Fleck and T. Zisis, The Erosion of EB-PVD Thermal Barrier Coatings: The Competition Between Mechanisms, Wear, 2010, 268(11–12), p 1214-1224

Acknowledgments

The authors would like to acknowledge financial support from KK foundation (Dnr 20140130), Sweden. The authors would also like to thank Mr. Martin Tandler from Institute of Energy and Climate Research (IEK-1), Forschungszentrum Jülich GmbH, for carrying out the erosion test.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 2016 International Thermal Spray Conference, held May 10-12, 2016, in Shanghai, P. R. China, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Mahade, S., Curry, N., Björklund, S. et al. Erosion Performance of Gadolinium Zirconate-Based Thermal Barrier Coatings Processed by Suspension Plasma Spray. J Therm Spray Tech 26, 108–115 (2017). https://doi.org/10.1007/s11666-016-0479-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-016-0479-4