Abstract

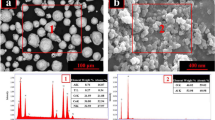

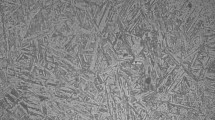

High-efficiency gas turbines require high-temperature sealing by use of abradable porous ceramic coatings to increase engine efficiency. In this study, porous Al2O3 coatings were deposited by flame spraying; the coatings were applied in a semi-molten state by controlled melting of the sprayed powder particles. The effects of the degree of melting of the sprayed particles, which depends on spraying conditions, on coating microstructure and porosity were investigated. The degree of melting of the sprayed particles was characterized by use of 3D confocal laser microscopy. The porosity of the coating was estimated by image analysis. The results showed that the degree of melting of alumina particles can be changed from 70 to 30%, and thus coating porosity can be increased from 30% up to over 70%. The standard hardness test yielded no useful data for porous coatings deposited by use of sprayed particles with a degree of melting <60%, and a hardness of 32–75 HR15Y for Al2O3 coatings deposited by use of sprayed particles with a degree of melting >60%. Pin-on-disk abrasion tests, performed at room temperature by use of an Inconel 738 (IN738) nickel-based superalloy pin with a spherical tip 5 mm in diameter, were conducted on the porous alumina coating to evaluate its abrasion behavior. It was found that for coatings of hardness <32 HR15Y and porosity >40% the wear weight loss of the IN738 pin was negligible despite the high rate of wear of the coating. It is evident that flame-sprayed porous alumina coatings of high porosity prepared by this approach have potential for use as abradable coatings for gas turbines operating at high temperatures.

Similar content being viewed by others

References

M. Dorfman, Challenges and Strategies for the Growth of Thermal Spray Markets: The Six-Pilar-Plans, J. Therm. Spray. Technol., 2013, 22, p 559-563

C.U. Hardwicke and Y.C. Lau, Advances in Thermal Spray Coatings for Gas Turbines and Energy Generation: A Review, J. Therm. Spray. Technol., 2013, 22, p 564-576

D.R. Clarke, M. Oechsner, and N.P. Padture, Thermal-Barrier Coatings for More Efficient Gas Turbine Engines, MRS Bull., 2012, 37, p 891-898

S.B. Lattime and B.M. Steinetz, High-Pressure-Turbine Clearance Control Systems: Current Practices and Future Directions, J. Propuls. Power, 2004, 20, p 302-331

J.R. Davis, Handbook of Thermal Spray Technology, ASM International, Materials Park, OH, 2004, p 178

H.I. Faraoun, T. Grosdidier, J.-L. Seichepine, D. Goran, H. Aourag, and C. Coddet, Improvement of Thermally Sprayed Abradable Coatings by Microstructure Control, Surf. Coat. Technol., 2006, 201, p 2303-2312

J. Matejicek, B. Kolman, J. Dubsky, K. Neufuss, N. Hopkins, and J. Zwick, Alternative Methods for Determination of Composition and Porosity in Abradable Materials, Mater. Charact., 2006, 57, p 17-29

E. Irissou, A. Dadouche, and R.S. Lima, Tribological Characterization of Plasma Sprayed CoNoCrAlY-BN Abradabe Coatings, J. Thermal Spray Technol., 2014, 23, p 252-261

Y. Nava, Z. Mutasim, and M. Coe, Ceramic Abradable Coatings for Applications up to 1100 °C, Thermal Spray 2001: New Surfaces for a New Millennium, C.C. Berndt, K.A. Khor, and E.F. Lugscheider, Ed., ASM International, Materials Park, 2001, p 119-126

A. Ang, N. Sanpo, M.L. Sesso, S.Y. Kim, and C.C. Berndt, Thermal Spray Maps: Materials Genomics of Processing Technology, J. Therm. Spray. Technol., 2013, 22, p 1170-1183

U. Bardi, C. Giolli, A. Scrivani, G. Rizzi, F. Borgiolli, K. Partes, T. Seefeld, D. Sporer, and A. Refke, Development and Investigation on New Composite and Ceramic Coatngs as Possible Abradable Seals, J. Therm. Spray. Technol., 2008, 17, p 805-811

S. Ebert, R. Mucke, D. Mack, R. Vasen, D. Stove, T. Wobst, and S. Gebhard, Failure Mechanisms of Magnesia Spinel Abradable Coatings Under Thermal Cyclic Loading, J. Eur. Ceram. Soc., 2013, 33, p 3335-3343

D. Sporer, M. Dorfman, L. Xie, R. Refke, I. Giovannetti, and M. Giannozzi, Processing and Properties of Advanced Abradable Ceramic Coatings, Thermal Spray 2007: Global Coatings Solutions, B.R. Marple, M.M. Hyland, Y.C. Lau, C.-J. Li, R.S. Lima, and G. Montavon, Ed., ASM International, Materials Park, OH, 2007, p 495-500

A. Scrivani, G. Rizzi, and C.C. Berndt, Enhanced Thick Thermal Barrier Coatings That Exhibit Varying Porosity, Mater. Sci. Eng. A, 2008, 476, p 1-7

A. Scrivani, G. Rizzi, U. Bardi, C. Giolli, M. Miranda, S. Ciattini, A. Fossati, and F. Borgioli, Thermal Fatigure Behavior of Thick and Porous Thermal Barrier Coatings Systems, J. Therm. Spray. Technol., 2007, 16, p 816-821

T. Steinke, G. Mauer, R. Vassen, D. Stover, D. Roth-Fagaraseanu, and M. Hancock, Process Design and Monitoring for Plasma Sprayed Abradable Coatings, J. Thermal Spray Technol., 2010, 19, p 756-764

J. Medricky, N. Curry, Z. Para, M. Vilemova, T. Chraska, and J. Johansson, Optimization of High Porosity Thermal Barrier Coatings Generated with a Porosity Former, J. Thermal Spray Technol., 2015, 24, p 622-628

C.-J. Li, G.J. Yang, C.X. Li, A Method to Produce Porous Materials, Chinese Patent, ZL 201210038361.6

C.-J. Li, G.-J. Yang, and C.-X. Li, Development of the Particle Interface Bonding in Thermal Spray Coatings: A Review, J. Thermal Spray Technol., 2013, 22, p 192-206

G.-J. Yang, C.-X. Li, S. Hao, Y.-Z. Xing, E.-J. Yang, and C.-J. Li, Critical Bonding Temperature for the Splat Bonding Formation during Plasma Spraying of Ceramic Materials, Surf. Coat. Technol., 2013, 235, p 841-847

B. Chen, C.-J. Li, G.-J. Yang, J.-T. Yao, H.-B. Huo, and C.-X. Li, Fabrication of Porous Molybdenum by Controlling Spray Particle State, J. Thermal Spray Technol., 2012, 21, p 1032-1104

J.-T. Yao, J.-Q. Ren, H.-B. Huo, G.-J. Yang, C.-X. Li, and C.-J. Li, Characteristics of Porous Metal Alloy Deposition by Flame Spraying of Semi-molten Spray Particles, J. Thermal Spray Technol., 2014, 23, p 991-999

J.-T. Yao, G.-J. Yang, C.-X. Li, and C.-J. Li, Fabrication of Porous Stainless Steel Through Semi-molten Spray Particle Deposition by Flame-Spraying, Mater. Manuf. Process., 2014, 29(10), p 1253-1259

J. Zou, C.-J. Li, H.-B. Huo, B. Chen, C.-X. Li, G.-J. Yang, Formation of Abradable Alumina Ceramic Coatings Through Deposition of Semi-molten Ceramic Particles by Flame Spray, Thermal Spray 2012: Proceedings from the International Thermal Spray Conference and Exposition,May 21-24, 2012, Houston, TX, R.S. Lima, A. Agarwal, M.M. Hyland, Y.-C. Lau, C.-J. Li, A. McDonald, F.-L. Toma, Ed, ASM International, Materials Park, pp. 126-130

S. Hao, C.-J. Li, and G.-J. Yang, Influence of Deposition Temperature on the Microstructures and Properties of Plasma-Sprayed Al2O3 Coatings, J. Thermal Spray Technol., 2011, 20, p 160-169

G.M. Nelson, J.A. Nychka, and A.G. McDonald, Structure, Phases, and Mechanical Response of Ti-Alloy Bioactive Glass Composite Coatings, Mater. Sci. Eng. C, 2014, 36, p 261-276

S.-L. Zhang, C.-J. Li, C.-X. Li, G.-J. Yang, and M. Liu, Deposition mechanism and microstructural evolution of plasma-sprayed superior La0.8Sr0.2Ga0.8Mg0.2O3 electrolyte for intermediate-temperature solid oxide fuel cells, J. Mater. Chem. A, 2015, 3, p 7535-7553

M. Boulos, P. Fauchais, A. Vardelle, and E. Pfender, Fundamentals of Plasma Particle Momentum and Heat Transfer, Plasma Spraying, Theory and Applications, R. Suryanarayanan, Ed., World Scientific Publishing Co, Singapore, 1993, p 3-57

J.M. Houben, Remarks Concerning a Rational Plasma for Thermal Spraying, General Aspect of Thermal Spraying, Proc. 9th Inter. Thermal Spray Conference, The Hague, 19-23 May 1980, Nederlands Instituut voor Lastechniek, Netherland, p 143-154

Acknowledgments

This project was financially supported by the Fund for the Doctoral Program of Higher Education of China (grant no. 20120201130002) and the National Basic Research Program of China (2012CB625100). The authors are grateful for the support from the European Program Marie Curie IPACTS (no. 268696).

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 2015 International Thermal Spray Conference, held May 11–14, 2015, in Long Beach, California, USA, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Li, CJ., Zou, J., Huo, HB. et al. Microstructure and Properties of Porous Abradable Alumina Coatings Flame-Sprayed with Semi-molten Particles. J Therm Spray Tech 25, 264–272 (2016). https://doi.org/10.1007/s11666-015-0287-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-015-0287-2