Abstract

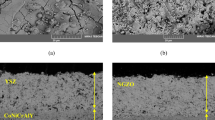

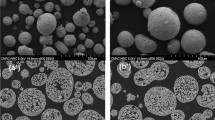

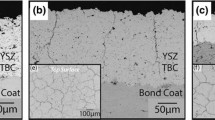

The higher operating temperatures in gas-turbine engines made possible by thermal barrier coatings (TBCs) are engendering a new problem: environmentally ingested airborne silicate particles (sand, ash) melt on the hot TBC surfaces and form calcium-magnesium-alumino-silicate (CMAS) glass deposits. The molten CMAS glass degrades the TBCs, leading to their premature failure. Here, we demonstrate the use of a commercially manufactured feedstock powder, in conjunction with air plasma spray process, to deposit CMAS-resistant yttria-stabilized zirconia-based TBCs containing Al3+ and Ti4+ in solid solution. Results from the characterization of these new TBCs and CMAS/TBCs interaction experiments are presented. The CMAS mitigation mechanisms in these new TBCs involve the crystallization of the anorthite phase. Raman microscopy is used to generate large area maps of the anorthite phase in the CMAS-interacted TBCs demonstrating the potential usefulness of this method for studying CMAS/TBCs interactions. The ubiquity of airborne sand/ash particles and the ever-increasing demand for higher operating temperatures in future high efficiency gas-turbine engines will necessitate CMAS resistance in all hot-section components of those engines. In this context, the versatility, ease of processing, and low cost offered by the process demonstrated here could benefit the development of these new CMAS-resistant TBCs.

Similar content being viewed by others

References

N.P. Padture, M. Gell, and E.H. Jordan, Thermal Barrier Coatings for Gas-Turbine Engine Applications, Science, 2002, 296(5566), p 280-284

A.G. Evans, D.R. Clarke, and C.G. Levi, The Influence of Oxides on the Performance of Advanced Gas Turbines, J. Eur. Ceram. Soc., 2008, 28(7), p 1405-1419

D.R. Clarke, M. Oechsner, and N.P. Padture, Thermal-Barrier Coatings for More Efficient Gas-Turbine Engines, MRS Bull., 2012, 37(10), p 891-898

J. Kim, M.G. Dunn, A.J. Baran, D.P. Wade, and E.L. Tremba, Deposition of Volcanic Materials in the Hot Sections of Two Gas Turbine Engines, J. Eng. Gas Turbines Power, 1993, 115(3), p 641-651

D.J. DeWet, R. Taylor, and F.H. Stott, Corrosion Mechanisms of ZrO2-Y2O3 Thermal Barrier Coatings in the Presence of Molten Middle-East Sand, J. Phys. IV., 1993, 3(C9), p 655-663

J.L. Smialek, F.A. Archer, and R.G. Garlick, Turbine Airfoil Degradation in the Persian Gulf War, JOM, 1994, 46(12), p 39-41

F.H. Stott, D.J. DeWet, and R. Taylor, Degradation of Thermal Barrier Coatings at Very High Temperatures, MRS Bull., 1994, 19(10), p 46-49

M.P. Borom, C.A. Johnson, and L.A. Peluso, Role of Environmental Deposits and Operating Surface Temperature in Spallation of Air Plasma Sprayed Thermal Barrier Coatings, Surf. Coat. Technol., 1996, 86-87, p 116-126

S. Krämer, J. Yang, C.G. Levi, and C.A. Johnson, Thermochemical Interaction of Thermal Barrier Coatings with Molten CaO-MgO-Al2O3-SiO2 (CMAS) Deposits, J. Am. Ceram. Soc., 2006, 89(10), p 3167-3175

A. Aygun, A.L. Vasiliev, N.P. Padture, and X. Ma, Novel Thermal Barrier Coatings that are Resistant to High-Temperature Attack by Glassy Deposits, Acta. Mater., 2007, 55(20), p 6734-6745

A.G. Evans and J.W. Hutchinson, The Mechanics of Coating Delamination in Thermal Gradients, Surf. Coat. Technol., 2007, 201(18), p 7905-7916

J.P. Bons, J. Crosby, J.E. Wammack, B.I. Bentley, and T.H. Fletcher, High Pressure Turbine Deposition in Land-Based Gas Turbines with Various Synfuels, J. Eng. Gas Turbines Power, 2005, 129(1), p 135-143

J.M. Crosby, S. Lewis, J.P. Bons, W.G. Ali, and T.H. Fletcher, Effects of Temperature and Size on Deposition in Land Based Turbines, J. Eng. Gas Turbines Power, 2008, 130(5), p 051503(1-9)

S. Krämer, J. Yang, and C.G. Levi, Infiltration-Inhibiting Reaction of Gadolinium Zirconate Thermal Barrier Coatings with CMAS Melts, J. Am. Ceram. Soc., 2008, 91(2), p 576-583

S. Krämer, S. Faulhaber, M. Chambers, D.R. Clarke, C.G. Levi, J.W. Hutchinson, and A.G. Evans, Mechanisms of Cracking and Delamination within Thick Thermal Barrier Systems in Aero-Engines Subject to Calcium-Magnesium-Alumino-Silicate (CMAS) Penetration, Mater. Sci. Eng., 2008, A 490(1-2), p 26-35

Z. Xue, A.G. Evans, and J.W. Hutchinson, Delamination Susceptibility of Coatings Under High Thermal Flux, J. App. Mech. Trans. ASME, 2009, 76(4), p 041008(1-7)

J.M. Drexler, A. Aygun, D. Li, R. Vaßen, T. Steinke, and N.P. Padture, Thermal-Gradient Testing of Thermal Barrier Coatings Under Simultaneous Attack by Molten Glassy Deposits and its Mitigation, Surf. Coat. Technol., 2010, 204(16-17), p 2683-2688

R. Wellman, G. Whitman, and J.R. Nicholls, CMAS Corrosion of EB-PVD TBCs: Identifying the Minimum Level to Initiate Damage, Int. J. Refract. Met., 2010, 28(1), p 124-132

J.M. Drexler, K. Shinoda, A.L. Ortiz, D. Li, A.L. Vasiliev, A.D. Gledhill, S. Sampath, and N.P. Padture, Air-Plasma-Sprayed Thermal Barrier Coatings that are Resistant to High-Temperature Attack by Glassy Deposits, Acta. Mater., 2010, 58(20), p 6835-6844

P. Mechnich, W. Braue, and U. Schulz, High-Temperature Corrosion of EB-PVD Yttria Partially Stabilized Thermal Barrier Coatings with an Artificial Volcanic Ash Overlay, J. Am. Ceram. Soc., 2011, 94(3), p 925-931

J. Wu, H.-B. Guo, Y.-Z. Gao, and S.-K. Gong, Microstructure and Thermo-Physical Properties of Yttria Stabilized Zirconia Coatings with CMAS Deposits, J. Eur. Ceram. Soc, 2011, 31(10), p 1881-1888

C.G. Levi, J.W. Hutchinson, M.-H. Vidal-Setif, and C.A. Johnson, Environmental Degradation of Thermal-Barrier Coatings by Molten Deposits, MRS Bull., 2012, 37(10), p 932-941

J. Webb, B. Casaday, B. Barker, J.P. Bons, A.D. Gledhill, and N.P. Padture, Coal Ash Deposition on Nozzle Guide Vanes—Part I: Experimental Characteristics of Four Coal Ash Types, J. Turbomach, 2013, 135(2), p 021033

P. Mohan, T. Patterson, B. Yao, and Y. Sohn, Degradation of Thermal Barrier Coatings by Fuel Impurities and CMAS: Thermochemical Interactions and Mitigation Approaches, J. Therm. Spray Technol., 2010, 19(1-2), p 156-167

J.M. Drexler, A.D. Gledhill, K. Shinoda, A.L. Vasiliev, K.M. Reddy, S. Sampath, and N.P. Padture, Jet Engine Coatings for Resisting Volcanic Ash Damage, Adv. Mater., 2011, 23(21), p 2419-2424

J.M. Drexler, A.L. Ortiz, and N.P. Padture, Composition Effects of Thermal Barrier Coating Ceramics on Their Interaction with Molten Ca-Mg-Al-Silicate (CMAS) Glass, Acta. Mater., 2012, 60(15), p 5437-5447

M. Freling, M.J. Maloney, D.A. Litton, K.W. Schlichting, J.G. Smeggil, and D.B. Snow, Thermal Barrier Coating Compositions, Processes for Applying Same and Articles Coated with Same, U.S. Patent No., 7,455,913 (2008)

M. Freling, K.W. Schlichting, M.J. Maloney, D.A. Litton, J.G. Smeggil, and D.B. Snow, CMAS Resistant Thermal Barrier Coating, U.S. Patent No., 7,785,722 (2010)

D.A. Litton, K.W. Schlichting, M. Freling, J.G. Smeggil, D.B. Snow, and M.J. Maloney, Durable Reactive Thermal Barrier Coatings, U.S. Patent No., 7,662,489 (2010)

A.D. Gledhill, K.M. Reddy, J.M. Drexler, K. Shinoda, S. Sampath, and N.P. Padture, Mitigation of Damage from Molten Fly Ash to Air-Plasma-Sprayed Thermal Barrier Coatings, Mater. Sci. Eng. A, 2011, 528(24), p 7214-7221

J.M. Drexler, C.-H. Chen, A.D. Gledhill, K. Shinoda, S. Sampath, and N.P. Padture, Plasma Sprayed Gadolinium Zirconate Thermal Barrier Coatings that are Resistant to Damage by Molten Ca-Mg-Al-Silicate Glass, Surf. Coat. Technol., 2012, 206(19-20), p 3911-3916

A.M. Alper and G.H. Stewart, Science of Ceramics, Vol 3, Academic Press, London, 1967

A. Vaidya, V. Srinivasan, T. Streibl, M. Friis, W. Chi, and S. Sampath, Process Maps for Plasma Spraying of Yttria-Stabilized Zirconia: An Integrated Approach to Design, Optimization and Reliability, Mater. Sci. Eng. A, 2008, 497(1-2), p 239-253

W. Chi, S. Sampath, and H. Wang, Microstructure-Thermal Conductivity Relationships for Plasma-Sprayed Yttria-Stabilized Zirconia Coatings, J. Am. Ceram Soc., 2008, 91(8), p 2636-2645

S. Sampath, V. Srinivasan, A. Valarezo, A. Vaidya, and T. Streibl, Sensing, Control and In situ Measurement of Coating Properties: An Integrated Approach Towards Establishing Process-Property Correlations, J. Therm. Spray. Technol., 2009, 18(2), p 243-255

R.A. Young, The Rietveld Method, Oxford University Press, Oxford, 1993

L.B. McCusker, R.B.V. Dreele, D.E. Cox, D. Louer, and P. Scardi, Reitveld Refinement Guidelines, J. Appl. Cryst., 1999, 32(1), p 36-50

T. Roisel and J. Rodriguez-Carvajal, WinPLOTR: A Windows Tool for Powder Diffraction Pattern Analysis, Mater. Sci. Forum, 2011, 378-381, p 118-123

R.L. Parc, B. Champagnon, J. Dianoux, P. Jarry, and V. Martinez, Anorthite and CaAl2Si2O8 Glass: Low Frequency Raman Spectroscopy and Neutron Scattering, J. Non-Cryst. Solids, 2003, 323(1-3), p 155-161

Z.C. Ling, A. Wang, and B.L. Jolliff, Mineralogy and Geochemistry of Four Lunar Soils by Laser-Raman Study, Icarus, 2011, 211(1), p 101-113

H. Wang, R.B. Dinwiddie, and W.D. Porter, Development of a Thermal Transport Database for Air Plasma Sprayed ZrO2-Y2O3 Thermal Barrier Coatings, J. Therm. Spray Technol., 2010, 19(5), p 879-883

S. Lakiza, O. Fabrichnaya, M. Zinkevich, and F. Aldinger, On the Phase Relations in the ZrO2-YO1.5-AlO1.5 System, J. Alloys Compd., 2006, 420(1-2), p 237-245

Acknowledgements

We thank Ms. J. Freese, Ms. A. Krause, Dr. W.B. Choi, and Mr. T. Wentz for experimental assistance, and Dr. J. Liu (Sulzer-Metco) for developing and supplying the YSZ + Al + Ti feedstock powders. We are grateful to the Office of Naval Research for supporting this research (Grant No. N00014-12-10175, monitored by Dr. D. Shifler).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Senturk, B.S., Garces, H.F., Ortiz, A.L. et al. CMAS-Resistant Plasma Sprayed Thermal Barrier Coatings Based on Y2O3-Stabilized ZrO2 with Al3+ and Ti4+ Solute Additions. J Therm Spray Tech 23, 708–715 (2014). https://doi.org/10.1007/s11666-014-0077-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-014-0077-2