Abstract

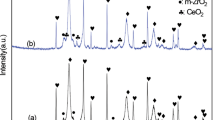

In-situ nanostructured FeAl2O4 composite coatings were prepared using plasma spraying of Al/Fe2O3 composite powders applying different spraying powers. The effects of plasma-spraying powers on microstructure and property of FeAl2O4 composite coatings were investigated. The results indicated the composite coatings had the microstructure with thin lamellar splats rich in FeAl2O4 as matrix, and dispersed granules rich in Fe and thin lamellar splats rich in Al2O3 as second phases. The reaction degree of Al/Fe2O3 composite powders increased while applying spraying power of 25-30 kW and then decreased while applying spraying power of 30-40 kW, which first resulted in the increase and then in the decrease of the Al2O3 content. The coating prepared by applying spraying power of 30 kW had the maximum microhardness, which was attributed to the maximum Al2O3 content present in the coating and the most uniform microstructure of the coating.

Similar content being viewed by others

References

V. Viswanathan, T. Laha, K. Balani, A. Agarwal, and S. Seal, Challenges and Advances in Nanocomposite Processing Techniques, Mater. Sci. Eng. R, 2006, 54, p 121-285

Y. Wang, W. Tian, and Y. Yang, Thermal Shock Behavior of Nanostructured and Conventional Al2O3/13 wt.%TiO2 Coatings Fabricated by Plasma Spraying, Surf. Coat. Technol., 2007, 201, p 7746-7754

F. Kikkawa, H. Tamura, and K. Kondo, Ti-B-C Composite Coating Produced by Electrothermally Exploded Powder-Spray Technique, J. Therm. Spray Technol., 2006, 15(1), p 92-96

M. Shahien, M. Yamada, T. Yasui, and M. Fukumoto, Cubic Aluminum Nitride Coating Through Atmospheric Reactive Plasma Nitriding, J. Therm. Spray Technol., 2010, 19(3), p 635-641

P. Bansal, N.P. Padture, and A.L. Vasiliev, Improved Interfacial Mechanical Properties of Al2O3-13 wt.%TiO2 Plasma-Sprayed Coatings Derived from Nanocrystalline Powders, Acta Mater., 2003, 51(10), p 2959-2970

Y. Wang, C.G. Li, W. Tian, and Y. Yang, Laser Surface Remelting of Plasma Sprayed Nanostructured Al2O3-13%TiO2 Coatings on Titanium Alloy, Appl. Surf. Sci., 2009, 255, p 8603-8610

W. Wang, F.Y. Hou, H. Wang, and H.T. Guo, Fabrication and Characterization of Ni-ZrO2 Composite Nano-Coatings by Pulse Electrodeposition, Scr. Mater., 2005, 53, p 613-618

Y.T. Pei, K.P. Shaha, C.Q. Chen, R. Hulst, A.A. Turkin, D.I. Vainshtein, and J.Th.M. De Hosson, Growth of Nanocomposite Films: From Dynamic Roughening to Dynamic Smoothening, Acta Mater., 2009, 57, p 5156-5164

Y. Yang, D.R. Yan, Y.C. Dong, X.G. Chen, L. Wang, J.X. Zhang, and J.N. He, Formation of Nanocrystalline FeAl2O4 Matrix Coating by Plasma Spraying, Surf. Eng., 2012, 28(5), p 333-337

J.S. Kim, Y.S. Kwon, O.I. Lomovsky, D.V. Dudina, V.F. Kosarev, S.V. Klinkov, D.H. KWon, and I. Smurov, Cold Spraying of In Situ Produced TiB2-Cu Nanocomposite Powders, Compos. Sci. Technol., 2007, 67, p 2292-2296

L. Pawlowski, Finely Grained Nanometric and Submicrometric Coatings by Thermal Spraying: A Review, Surf. Coat. Technol., 2008, 202, p 4318-4328

H. Wang, S. Zhang, J. Zhu, J. Huang, H. Liu, and H. Zhang, In Situ TiC-Reinforced Ni-Based Composite Coating Prepared by Flame Spraying Using Sucrose as the Source of Carbon, J. Therm. Spray Technol., 2009, 18(1), p 103-109

Y. Yang, D.R. Yan, Y.C. Dong, L. Wang, X.G. Chen, J.X. Zhang, J.N. He, and X.Z. Li, In Situ Nanostructured Ceramic Matrix Composite Coating Prepared by Plasma Spraying Composite Powders, J. Alloys Compd., 2011, 509, p L90-L94

L. Duraes, B.F.O. Costa, R. Santos, A. Correia, J. Campos, and A. Portugal, Fe2O3/Aluminum Thermite Reaction Intermediate and Final Products Characterization, Mater. Sci. Eng. A, 2007, 465, p 199-210

J. Mei, R.D. Halldearn, and P. Xiao, Mechanisms of the Al-Iron Oxide Thermite Reaction, Scr. Mater., 1999, 41, p 541-548

X.G. Chen, Y. Yang, D.R. Yan, Y.C. Dong, L. Wang, J.X. Zhang, J.N. He, and X.Z. Li, Microstructure and Properties of In Situ Nanostructured Ceramic Matrix Composite Coating Prepared by Plasma Spraying, J. Mater. Sci., 2011, 46, p 7369-7376

D.R. Yan, Y.C. Dong, Y. Yang, L. Wang, X.G. Chen, J.N. He, and J.X. Zhang, Microstructure Characterization of the FeAl2O4-Based Nanostructured Composite Coating Synthesized by Plasma Spraying Fe2O3/Al Powders, J. Therm. Spray Technol., 2011, 20, p 1269-1277

L. Pawlowski, The Science and Engineering of Thermal Spray Coatings, 2nd ed., Wiley, Chichester, 2008, p 167-521

Acknowledgments

The authors gratefully acknowledge the financial supports of the National Natural Science Foundation of China (51072045, 51102074 and 51272065); China Postdoctoral Science Foundation (20110490979) and Project (20101317120005) supported by Doctoral Program Specialized Research Foundation for Universities, China; and Outstanding Youth Fund for Science and Technology Research of Universities in Hebei Province (Y2012003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, Y., Yan, Dr., Dong, Yc. et al. Effects of Plasma-spraying Powers on Microstructure and Microhardness of In-Situ Nanostructured FeAl2O4 Composite Coatings. J Therm Spray Tech 22, 1002–1006 (2013). https://doi.org/10.1007/s11666-013-9944-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-013-9944-5