Abstract

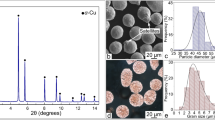

The sintering of free-standing plasma sprayed TBCs has been modeled, based on variational principles of free energy minimization and comparisons are made with experimental results. Predictions of through-thickness shrinkage and changing pore surface area are compared with the experimental data obtained by dilatometry and BET analysis, respectively. The sensitivity of the predictions to initial pore architecture and material properties is assessed. The model can be used to predict the evolution of the contact area between overlying splats. This is in turn related to the through-thickness thermal conductivity, using a previously developed analytical model (I.O. Golosnoy, et al. J. Therm. Spray Technol., 2005, 14(2), p 205-214).

Similar content being viewed by others

Abbreviations

- A s :

-

Total free surface area, m2

- A gb :

-

Total grain boundary area, m2

- D 0 :

-

Diffusivity, m2 s−1

- E :

-

Young’s modulus, Pa

- \(\overline{G}\) :

-

Free energy per unit volume, J m−3

- h :

-

Height from the centre of the bridge to the centre of the splat, m

- J :

-

Volumetric flux per unit depth, m3 m−1 s−1

- k :

-

Thermal conductivity, W m−1 K−1

- k B :

-

Boltzman constant, J atom−1 K−1

- M :

-

Atomic mobility, m2 J−1 s−1

- N s :

-

Number of grains within a splat

- Q :

-

Activation energy, J mol−1

- r b :

-

Radius of contact between splats, m

- r g :

-

Grain size (side of hexagonal prism), m

- r s :

-

Radius of the splat, m

- R :

-

Universal gas constant, J mol−1 K−1

- T :

-

Absolute temperature, K

- Vol:

-

Volume of material corresponding to a unit cell, m3

- \(v_\bot\) :

-

Migration velocity of an interface, m s−1

- y b :

-

Half open-pore dimension, m

- y s :

-

Half-height of the splat, m

- \(\updelta\) :

-

Thickness of the layer, through which diffusion takes place, m

- \(\upgamma_{\rm s}\) :

-

Specific surface energy, J m−2

- \(\upgamma_{\rm gb}\) :

-

Specific grain boundary energy, J m−2

- \(\overline{\Uppsi}\) :

-

Rate of energy dissipation per unit volume, J s−1 m−3

- \(\Upomega \) :

-

Atomic volume, m3

References

A. Needleman, J.R. Rice, Plastic Creep Flow Effects in the Diffusive Cavitation of Grain Boundaries. Acta Metall. 28, 1315-1332 (1980)

J. Pan, A.C.F. Cocks, A Numerical Technique for the Analysis of Coupled Surface and Grain-Boundary Diffusion. Acta Metall. Mater. 43(4), 1395-1406 (1995)

A.C.F. Cocks, Variational Principles, Numerical Schemes and Bounding Theorems for Deformation by Nabarro-Herring Creep. J. Mech. Phys. Solids 44(9), 1429-1452 (1996)

A.C.F. Cocks, S.P.A. Gill, A Variational Approach to Two Dimensional Grain Growth - I. Theory. Acta Mater. 44(12), 4765-4775 (1996)

Z. Suo, W. Wang, Diffusive Void Bifurcation in Stressed Solid. J. Appl. Phys. 76(6), 3410-3421 (1994)

J. Svoboda, et al., Diffusion in Multi-Component Systems with No or Dense Sources and Sinks for Vacancies. Acta Mater. 50, 1369-1381 (2002)

R.G. Hutchinson, N.A. Fleck, A.C.F. Cocks, A Sintering Model for Thermal Barrier Coatings. Acta Mater. 54(5), 1297-1306 (2006)

J. Svoboda, H. Riedel, Quasi-Equilibrium Sintering for Coupled Grain-Boundary and Surface Diffusion. Acta Metall. Mater. 43(2), 499-506 (1995)

B. Sun, Z. Suo, A.C.F. Cocks, A Global Analysis of Structural Evolution in a Row of Grains. J. Mech. Phys. Solids 44(4), 559-581 (1996)

F. Parhami, et al., A Model for the Sintering and Coarsening of Rows of Spherical Particles. Mech. Mater. 31, 43-61 (1999)

H.H. Yu, Z. Suo, An Axisymmetric Model of Pore-Grain Boundary Separation. J. Mech. Phys. Solids 47, 1131-1155 (1999)

M. Saitou, Analysis of the Initial Stage of Sintering in Pure Materials by Surface Diffusion. Phil. Mag. Letts. 79(5), 257-263 (1999)

M. Saitou, Analysis of Sintering of Two Cylindrical Particles by Lattice or Grain Boundary Diffusion at the Initial Stage. Phil. Mag. Letts. 79(11), 877-885 (1999)

J. Pan, A.C.F. Cocks, S. Kucherenko, Finite Element Formulation of Coupled Grain-Boundary and Surface Diffusion with Grain-Boundary Migration. Proc. Roy. Soc. Lond. A 453, 2161-2184 (1997)

A.C.F. Cocks, S.P.A. Gill, J. Pan, Modeling Microstructure Evolution in Engineering Materials. Adv. Appl. Mech. 36, 81-162 (1999)

J. Pan, Modelling Sintering at Different Length Scales. Int. Mater. Rev. 48(2), 69-85 (2003)

J. Pan and H.N. Ch’ng, Virtual Power Principle and Sintering Models at Particle Scale, Proceedings of the 4th International Conference on Science, Technology and Applications of Sintering, Grenoble, France, 2005

S. Paul, et al., Effects of Impurity Content on the Sintering Characteristics of Plasma Sprayed Zirconia, submitted to J. Therm. Spray Technol., 2007

A.J. Allen, et al., Microstructural Characterization of Yttria-Stabilized Zirconia Plasma-Sprayed Deposits using Multiple Small-Angle Neutron Scattering. Acta Mater. 49, 1661-1675 (2001)

A.M.J. Mayo, Zr Surface Diffusion in Tetragonal Yttria Stabilized Zirconia. J. Mater. Sci. 35, 437-442 (2000)

Y. Sakka, et al., Cation Interdiffusion and Phase Stability in Polycrystalline Tetragonal Ceria-Zirconia-Hafnia Solid Solution. J. Am. Cer. Soc. 74(10), 2610-2614 (1991)

R.N. German, Sintering Theory and Practice, 1st ed., John Wiley & Sons, New York, 1996, p 534

S. Brunauer, P.H. Emmett, E. Teller, Adsorption of Gases in Multimolecular Layers. J. Am. Chem. Soc. 60, 309-319 (1938)

I.O. Golosnoy, S.A. Tsipas, T.W. Clyne, An Analytical Model for Simulation of Heat Flow in Plasma Sprayed Thermal Barrier Coatings. J. Therm. Spray Technol. 14(2), 205-214 (2005)

Acknowledgments

Financial support has come from a Basque Government scholarship (for AC), from EPSRC via Platform Grant and from Sulzer Metco (US) Inc. The authors are also grateful for extensive useful discussions with Sulzer Metco personnel, particularly Mitch Dorfman, Clive Britton, Keith Harrison, Liangde Xie and Jason Doesburg.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 2007 International Thermal Spray Conference and has been expanded from the original presentation. It is simultaneously published in Global Coating Solutions, Proceedings of the 2007 International Thermal Spray Conference, Beijing, China, May 14-16, 2007, Basil R. Marple, Margaret M. Hyland, Yuk-Chiu Lau, Chang-Jiu Li, Rogerio S. Lima, and Ghislain Montavon, Ed., ASM International, Materials Park, OH, 2007.

Rights and permissions

About this article

Cite this article

Cipitria, A., Golosnoy, I. & Clyne, T. Sintering Kinetics of Plasma-Sprayed Zirconia TBCs. J Therm Spray Tech 16, 809–815 (2007). https://doi.org/10.1007/s11666-007-9080-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-007-9080-1