Abstract

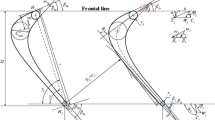

Residual stress and distortion are inevitable during metal selective laser melting (SLM) process due to the high thermal gradient. Based on an experimental investigation and a numerical simulation, this paper studied the effect of geometric size and structural feature on the residual stress and distortion of hollow Ti-alloy blades fabricated using SLM. The results indicated that the distortion of blades increased with the increase in height and torsion angle of the blades. However, distortion obviously decreased when the stiffened plates were set inside the blades and the blade thickness increased. When the number of stiffened plates increased from zero to three and the blade thickness increased from 0.5 to 2 mm, the distortion value was reduced by the biggest rate of 38 and 35%, respectively. In addition, the residual stress along the building direction was found to play a dominant role in inducing the distortion. This study showed a new viewpoint to reduce the distortion by optimizing the geometric size and structural feature of a metal part.

Similar content being viewed by others

References

Y.M. Wang, T. Voisin, J.T. Mckeown, J. Ye, N.P. Calta, Z. Li, Z. Zeng, Y. Zhang, W. Chen and T.T. Roehling, Additively Manufactured Hierarchical Stainless Steels with High Strength and Ductility, Nat. Mater., 2017, 17, p 1.

W. Jin, C. Zhang, S. Jin, Y. Tian, D. Wellmann and W. Liu, Wire Arc Additive Manufacturing of Stainless Steels: A Review, Appl. Sci., 2020, 10(5), p 1563.

D. Herzog, V. Seyda, E. Wycisk and C. Emmelmann, Additive Manufacturing of Metals, Acta Mater., 2016, 117, p 371–392.

T. DebRoy, H.L. Wei, J.S. Zuback, T. Mukherjee, J.W. Elmer, J.O. Milewski, A.M. Beese, A. Wilson-Heid, A. De and W. Zhang, Additive Manufacturing of Metallic Components: Process, Structure and Properties, Prog. Mater. Sci., 2018, 92, p 112–224.

L. Zai, C. Zhang, Y. Wang, W. Guo, D. Wellmann, X. Tong and Y. Tian, Laser Powder Bed Fusion of Precipitation-Hardened Martensitic Stainless Steels: A Review, Metals, 2020, 10(2), p 255.

W.E. Frazier, Metal Additive Manufacturing: A Review, J. Mater. Eng. Perform., 2014, 23(6), p 1917–1928.

Y. Yang, C. Zhang, D. Wang, L. Nie, D. Wellmann and Y. Tian, Additive Manufacturing of WC-Co Hardmetals: A Review, Int. J. Adv. Manuf. Technol., 2020, 108, p 1653–1673.

J.H. Martin, B.D. Yahata, J.M. Hundley, J.A. Mayer, T.A. Schaedler and T.M. Pollock, 3D Printing of High-Strength Aluminium Alloys, Nature, 2017, 549(7672), p 365.

T. Voisin, N.P. Calta, S.A. Khairallah, J.-B. Forien, L. Balogh, R.W. Cunningham, A.D. Rollett and Y.M. Wang, Defects-Dictated Tensile Properties of Selective Laser Melted Ti–6Al–4V, Mater. Des., 2018, 158, p 113–126.

C. Li, C.H. Fu, Y.B. Guo and F.Z. Fang, Fast Prediction and Validation of Part Distortion in Selective Laser Melting, Proc. Manuf., 2015, 1, p 355–365.

D. Buchbinder, N. Pirch, K. Wissenbach, J. Schrage and W. Meiners, Investigation on Reducing Distortion by Preheating During Manufacture of Aluminum Components Using Selective Laser Melting, J. Laser Appl., 2014, 26(1), p 012004.

A.S. Wu, D.W. Brown, M. Kumar, G.F. Gallegos and W.E. King, An Experimental Investigation into Additive Manufacturing-Induced Residual Stresses in 316L Stainless Steel, Metallurg. Mater. Trans. A, 2014, 45(13), p 6260–6270.

J.-P. Kruth, J. Deckers, E. Yasa and R. Wauthlé, Assessing and Comparing Influencing Factors of Residual Stresses in Selective Laser Melting Using a Novel Analysis Method, Proc. Inst. Mech. Eng. Pt. B J. Eng. Manuf., 2012, 226(6), p 980–991.

M.F. Zaeh and G. Branner, Investigations on Residual Stresses and Deformations in Selective Laser Melting, Prod. Eng., 2009, 4(1), p 35–45.

E. Mirkoohi, D.E. Sievers, H. Garmestani, K. Chiang and S.Y. Liang, Three-Dimensional Semi-Elliptical Modeling of Melt Pool Geometry Considering Hatch Spacing and Time Spacing in Metal Additive Manufacturing, J. Manuf. Process., 2019, 45, p 532–543.

R. Liu, S. Xu, X. Shao, Y. Wen, X. Shi, L. Huang, M. Hong, J. Hu and Z. Yang, Defect-Engineered NiCo-S Composite as a Bifunctional Electrode for High-Performance Supercapacitor and Electrocatalysis, ACS Appl. Mater. Interf., 2021, 13(40), p 47717–47727.

A. Vasinonta, J.L. Beuth and M. Griffith, Process Maps for Predicting Residual Stress and Melt Pool Size in the Laser-Based Fabrication of Thin-Walled Structures, J. Manuf. Sci. Eng., 2007, 129(1), p 101–109.

K. Dai and L. Shaw, Distortion minimization of laser-processed components through control of laser scanning patterns, Rapid Prototyp. J., 2002, 8(5), p 270–276.

H. Ali, H. Ghadbeigi and K. Mumtaz, Effect of scanning strategies on residual stress and mechanical properties of selective laser melted Ti6Al4V, Mater. Sci. Eng. A, 2018, 712, p 175–187.

M. Masoomi, S.M. Thompson and N. Shamsaei, Laser powder bed fusion of Ti–6Al–4V parts: thermal modeling and mechanical implications, Int. J. Mach. Tools Manuf., 2017, 118–119, p 73–90.

Z. Tian, C. Zhang, D. Wang, W. Liu, X. Fang, D. Wellmann, Y. Zhao and Y. Tian, A review on laser powder bed fusion of inconel 625 nickel-based alloy, Appl. Sci., 2019, 10, p 81.

Z. Li, R. Xu, Z. Zhang and I. Kucukkoc, The influence of scan length on fabricating thin-walled components in selective laser melting, Int. J. Mach. Tools Manuf., 2018, 126, p 1–12.

T. Mukherjee, W. Zhang and T. Debroy, An Improved Prediction of Residual Stresses and Distortion in Additive Manufacturing, Comput. Mater. Sci., 2017, 126, p 360–372.

J. Cao, M.A. Gharghouri and P. Nash, Finite-element analysis and experimental validation of thermal residual stress and distortion in electron beam additive manufactured Ti–6Al–4V build plates, J. Mater. Process. Technol., 2016, 237, p 409–419.

Y. Zhang, L. Yu, Z. Fang, N.N. Xiong, L. Zhang and H. Tian, An End-to-End Deep Learning Model for Robust Smooth Filtering Identification, Fut. Gener. Comput. Syst., 2022, 127, p 263–275.

D. Gu and B. He, Finite Element Simulation and Experimental Investigation of Residual Stresses in Selective Laser Melted Ti–Ni Shape Memory Alloy, Comput. Mater. Sci., 2016, 117, p 221–232.

R. Liu, S. Xu, X. Shao, Y. Wen, X. Shi, J. Hu and Z. Yang, Carbon Coating on Metal Oxide Materials for Electrochemical Energy Storage, Nanotechnology, 2021, 32(50), p 502004.

M. Bugatti and Q. Semeraro, Limitations of the inherent strain method in simulating powder bed fusion processes, Addit. Manuf., 2018, 23, p 329–346.

L. Bass, J. Milner, T. Gnäupel-Herold, S. Moylan, Residual Stress in Additive Manufactured Nickel Alloy 625 Parts, J. Manuf. Sci. Eng. 140(6) (2018).

S. Afazov, W.A. Denmark, B.L. Toralles, A. Holloway and A. Yaghi, Distortion Prediction and Compensation in Selective Laser Melting, Addit. Manuf., 2017, 17, p 15–22.

G. Shuang, Z. Tan, L. Lan and B. He, Effects of geometrical size and structural feature on the shape-distortion behavior of hollow Ti-alloy blade fabricated by additive manufacturing process, J. Laser Appl., 2020, 32, p 032005.

K. Dai and L.L. Shaw, Finite element analysis of the effect of volume shrinkage during laser densification, Acta Mater., 2005, 53(18), p 4743–4754.

A. Hussein, L. Hao, C. Yan and R.M. Everson, Finite element simulation of the temperature and stress fields in single layers built without-support in selective laser melting, Mater. Des., 2013, 52, p 638–647.

B.S. Yilbas and A.F.M. Arif, Material response to thermal loading due to short pulse laser heating, Int. J. Heat Mass Transf., 2001, 44(20), p 3787–3798.

S.A. Tsirkas, P. Papanikos and T.B. Kermanidis, Numerical simulation of the laser welding process in butt-joint specimens, J. Mater. Process. Technol., 2003, 134(1), p 59–69.

Z. Xiao, C. Chen, Z. Hu, H. Zhu and X. Zeng, Effect of rescanning cycles on the characteristics of selective laser melting of Ti6Al4V, Opt. Laser Technol., 2020, 122, p 105890.

Y.C.S. Shunyu Liu, Additive manufacturing of Ti6Al4V alloy: a review, Mater. Des., 2019, 164, p 1–23.

H. Ali, L. Ma, H. Ghadbeigi and K. Mumtaz, In-situ residual stress reduction, martensitic decomposition and mechanical properties enhancement through high temperature powder bed pre-heating of Selective Laser Melted Ti6Al4V, Mater. Sci. Eng. A, 2017, 695, p 211–220.

S. Gao, Z.J. Tan, L. Lan and B. He, Effects of geometrical size and structural feature on the shape-distortion behavior of hollow Ti-alloy blade fabricated by additive manufacturing process, J. Laser Appl., 2020, 32, p 3.

G. Vastola, G. Zhang, Q. Pei and Y.W. Zhang, Controlling of residual stress in additive manufacturing of Ti6Al4V by finite element modeling, Add. Manuf., 2016, 12, p 231–239.

N.S. Bailey, W. Tan and Y.C. Shin, Predictive modeling and experimental results for residual stresses in laser hardening of AISI 4140 steel by a high power diode laser, Surf. Coat. Technol., 2009, 203(14), p 2003–2012.

P. Mercelis and J. Kruth, Residual stresses in selective laser sintering and selective laser melting, Rapid Prototyp. J., 2006, 12(5), p 254–265.

Y. Liu, Y. Yang and D. Wang, A study on the residual stress during selective laser melting (SLM) of metallic powder, Int. J. Adv. Manuf. Technol., 2016, 87(1), p 647–656.

Z. Wang, E. Denlinger, P. Michaleris, A.D. Stoica, D. Ma and A.M. Beese, Residual stress mapping in Inconel 625 fabricated through additive manufacturing: method for neutron diffraction measurements to validate thermomechanical model predictions, Mater. Des., 2017, 113, p 169–177.

S. Afazov, W.A.D. Denmark, B. Lazaro Toralles, A. Holloway and A. Yaghi, Distortion prediction and compensation in selective laser melting, Addit. Manuf., 2017, 17, p 15–22.

Acknowledgments

This work was supported by the Shanghai Sailing Program [19YF1417500] and Open Project of State Key Laboratory of Advanced Special Steel, Shanghai Key Laboratory of Advanced Ferrometallurgy, Shanghai University (SKLASS2020-10) and the Science and Technology Commission of Shanghai Municipality (No. 19DZ2270200)

Author information

Authors and Affiliations

Contributions

Shuang Gao*: Conceptualization, Methodology, Resources, Writing - review & editing, Supervision. Zhijun Tan: Conceptualization, Methodology, Validation, Formal analysis, Investigation, Data curation, Writing - original draft. Zhenfeng Song: Conceptualization, Formal analysis. Liang Lan: Conceptualization, Formal analysis. Bo He*: Conceptualization, Formal analysis, Project administration, Funding acquisition.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gao, S., Tan, Z., Lan, L. et al. Experimental Investigation and Numerical Simulation of Residual Stress and Distortion of Ti6Al4V Components Manufactured Using Selective Laser Melting. J. of Materi Eng and Perform 31, 8113–8123 (2022). https://doi.org/10.1007/s11665-022-06815-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06815-3